Paint roller case

a roller case and roller technology, applied in the field of roller cases, can solve the problems of wasting the roller case, affecting the quality of the product, and requiring separate tools, etc., and achieve the effect of saving the cost and complexity of the invention, and avoiding the use of separate tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

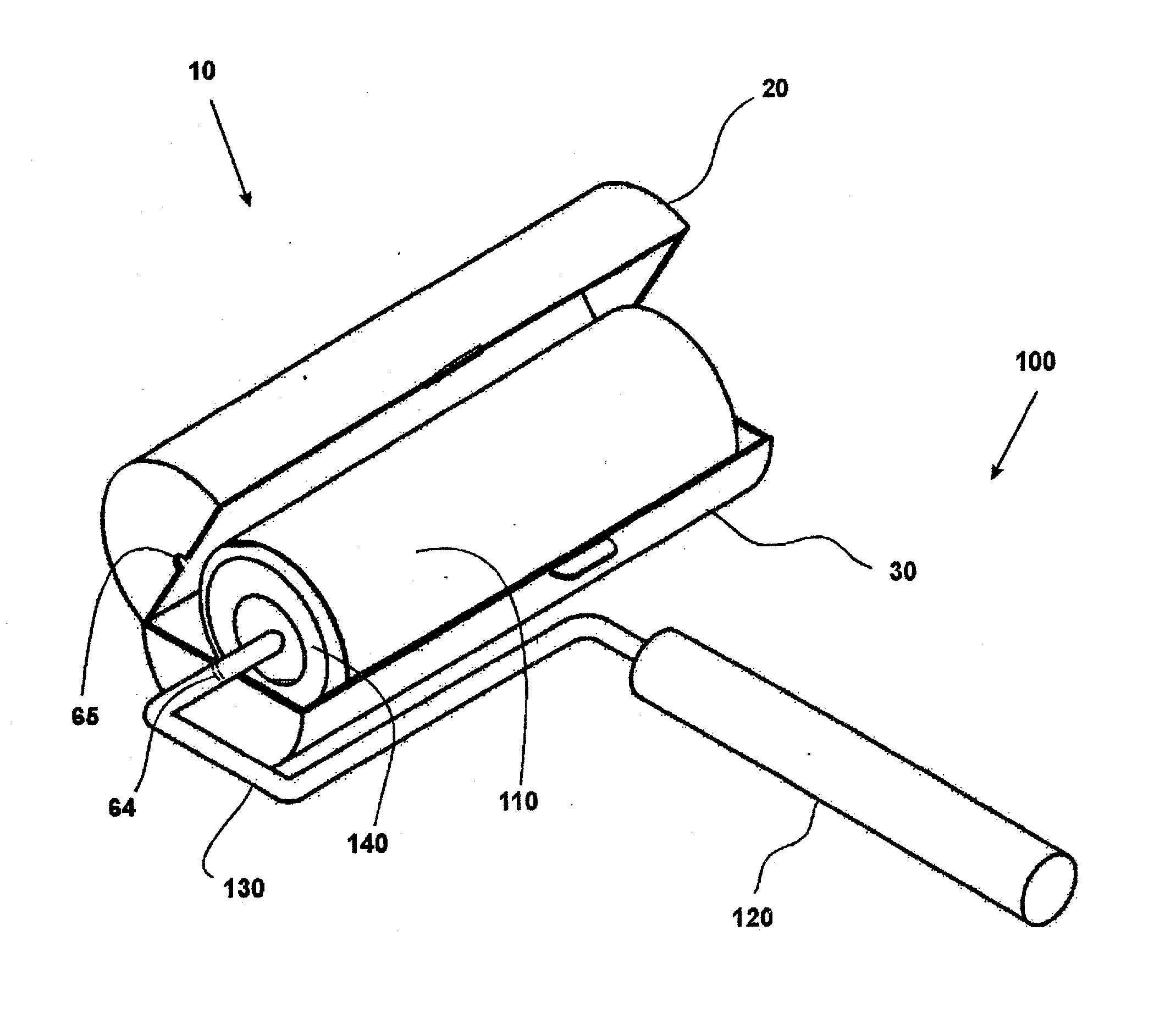

[0017] In accordance with the present invention, FIG. 1 shows a perspective view of the paint roller case 10, and paint roller assembly 100.

[0018] Paint roller assembly 100 comprises roller handle 120, roller shaft 130, roller 140 and roller cover 110. Roller cover 110 is shown inside case bottom 30. Roller shaft 130 protrudes through a hole 64 in case bottom 30. Hole 65 in case top 20 corresponds to the hole 64 in case bottom 30, providing clearance for roller shaft 130.

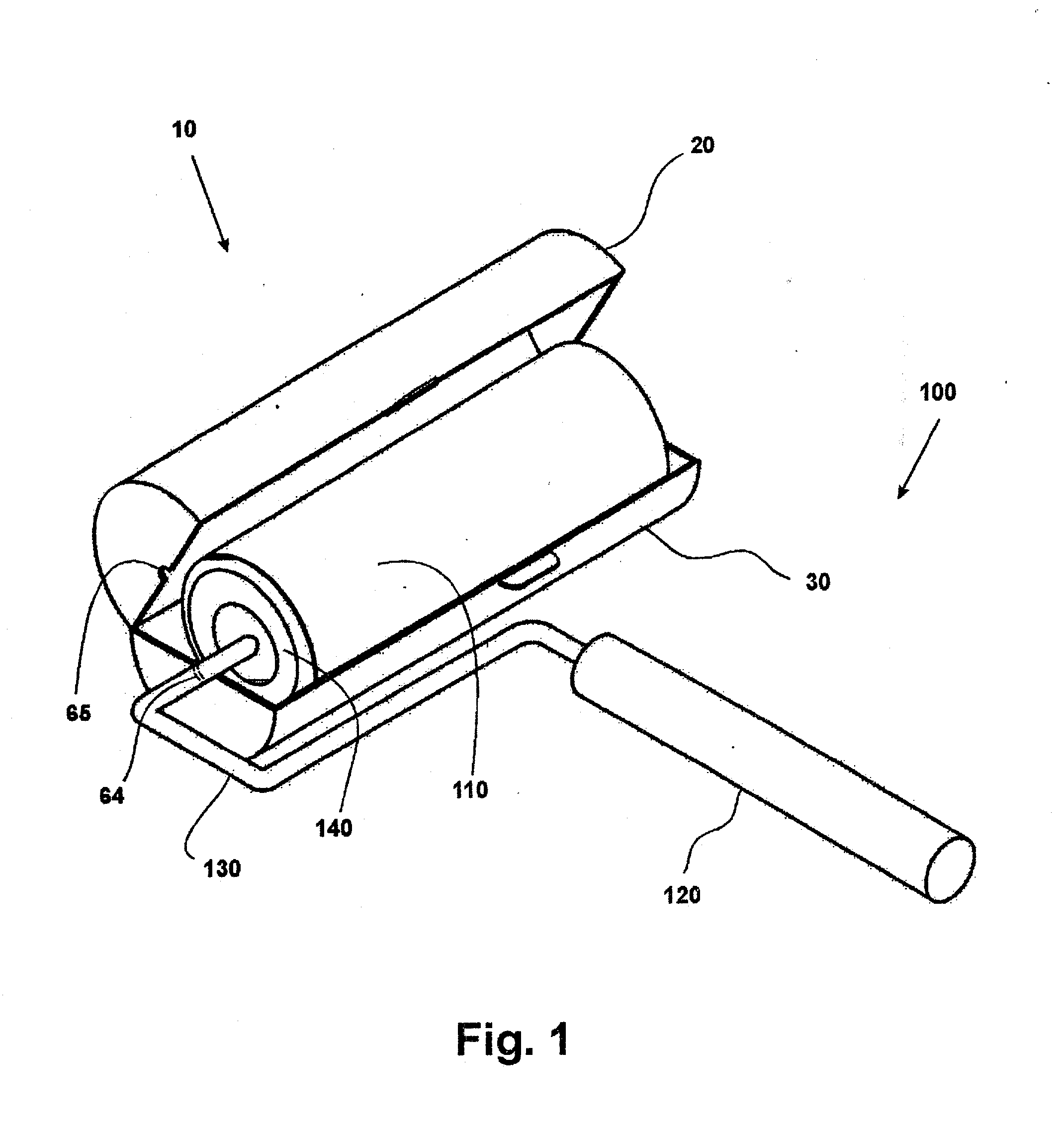

[0019] FIG. 2 shows paint roller case 10 in the closed position. Case bottom 30 is slightly overlapped at 80 by case top 20. This provides for a substantially airtight condition. Case top 20 and case bottom 30 are maintained in the closed position by friction interaction between top latch 40 and bottom latch 50.

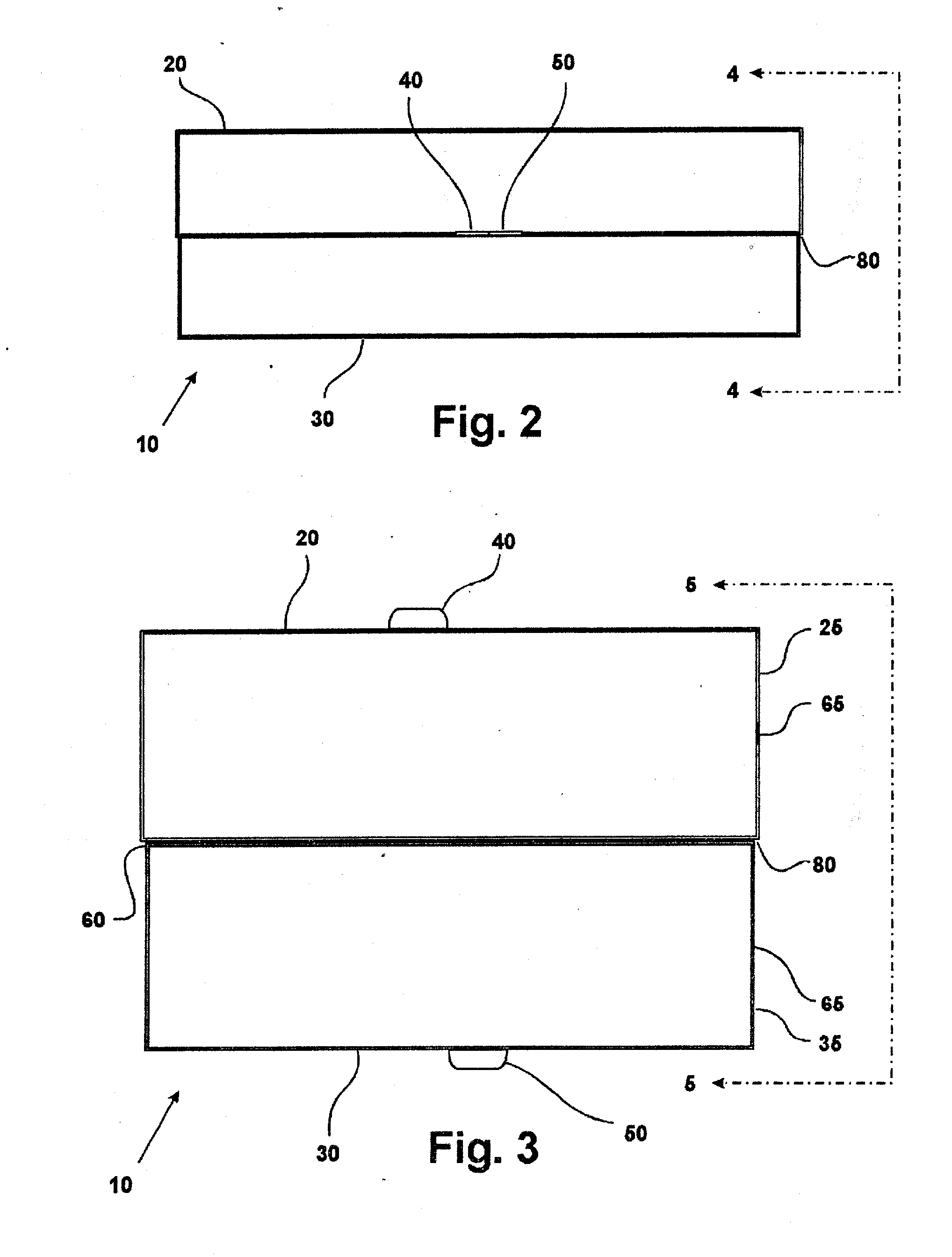

[0020] FIG. 3 shows paint roller case 10 in the opened position. Case top 20 is slightly longer than case bottom 30, creating overlap 80. This provides the substantially airtight condition. Plastic hinge 60 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com