Inner sleeve constraint folding steel plate energy dissipation support

An energy-dissipating support and inner casing technology, which is applied to building components, shock-proof and other directions, can solve the problems that the energy-dissipation performance of the support cannot be accurately controlled, the position of the yield point of the core board cannot be controlled, and the energy-dissipation capacity of the core board cannot be exerted. To achieve the effect of simple structure, preventing buckling under compression, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

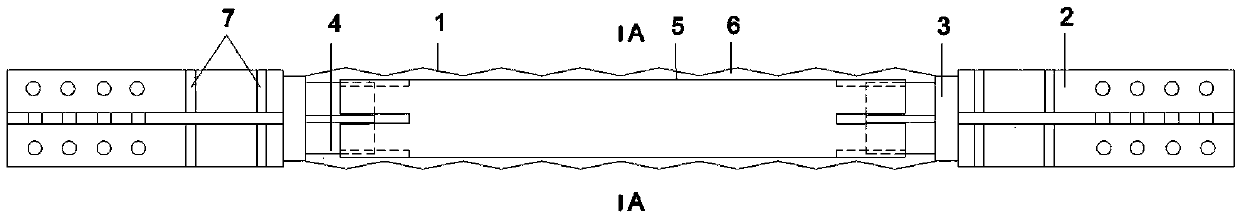

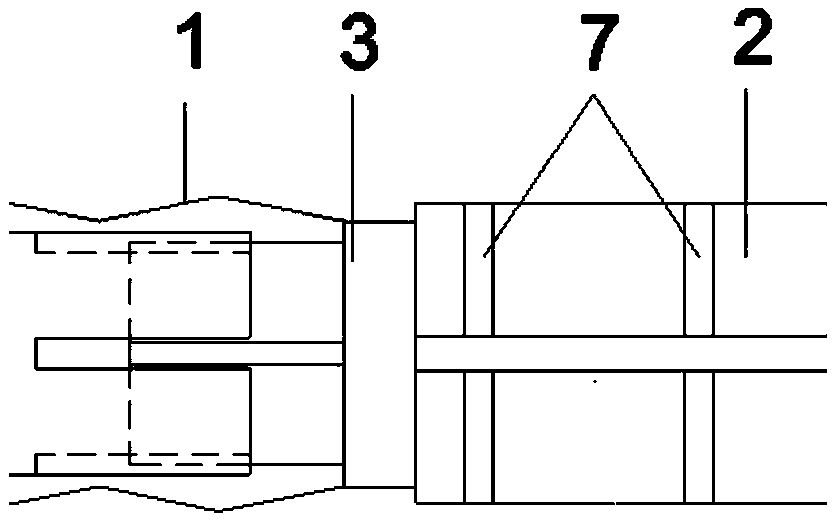

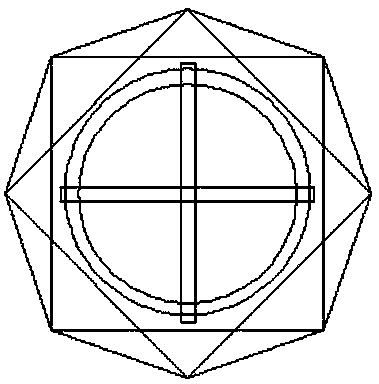

[0036] like Figure 1 to Figure 5 Shown, the present invention is made up of core tube 1, cross gusset plate 2, end bearing plate 3, cross fixing plate 4, inner casing 5, non-adhesive material 6, and stiffener 7 seven parts. The core barrel 1 is formed by punching steel plates into different simple geometric figures, and then welded to form a cylindrical shape. As shown in FIG. 4 , in this embodiment, the geometric figure on the core barrel 1 is a combination of isosceles triangles. It is folded like Figure 5 As shown, it is the crease pattern in this embodiment, the two ends are welded to form the core tube 1, and the dotted line is the dent. like figure 2 As shown, the end pressure plate 3 is connected to the core barrel 1, and the end pressure plate 3 is welded to the four sides of the mouth of the core barrel 1, and the size of the end pressure plate 3 is the same as that of the mouth of the core barrel 1. At the same time, the cross fixing plate 4 is welded on the i...

Embodiment 2

[0038] This embodiment is the same as the rest of Embodiment 1, except that the circular tube of the inner casing 5 is replaced by a square tube to provide constraints.

[0039]In order to express the spatial structure of the subunit more clearly, establish a space Cartesian coordinate system to describe the coordinates of each node, as shown in Figure 8, the coordinate origin O is the center of the subunit, and the straight line where the diagonal FH of the quadrilateral EFGH is located is used as the X axis , from F to H is the positive direction, take the straight line where the other diagonal EG of the quadrilateral is located as the Z-axis, point from E to G as the positive direction, and take the straight line passing through point O and perpendicular to the X-axis and Z-axis as the Y-axis, The positive direction is from the plane ABCD to the plane IJKL.

[0040] The size of the energy dissipation unit should meet the following conditions (θ is the dihedral angle between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com