Self-resetting beam column friction energy dissipation joint structure and construction method thereof

A node structure, friction energy consumption technology, applied in the direction of buildings, building types, building components, etc., can solve the problems of serious node damage, large residual deformation, difficult control, etc., to achieve good energy consumption performance, simple structural form, mechanical Model explicit effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

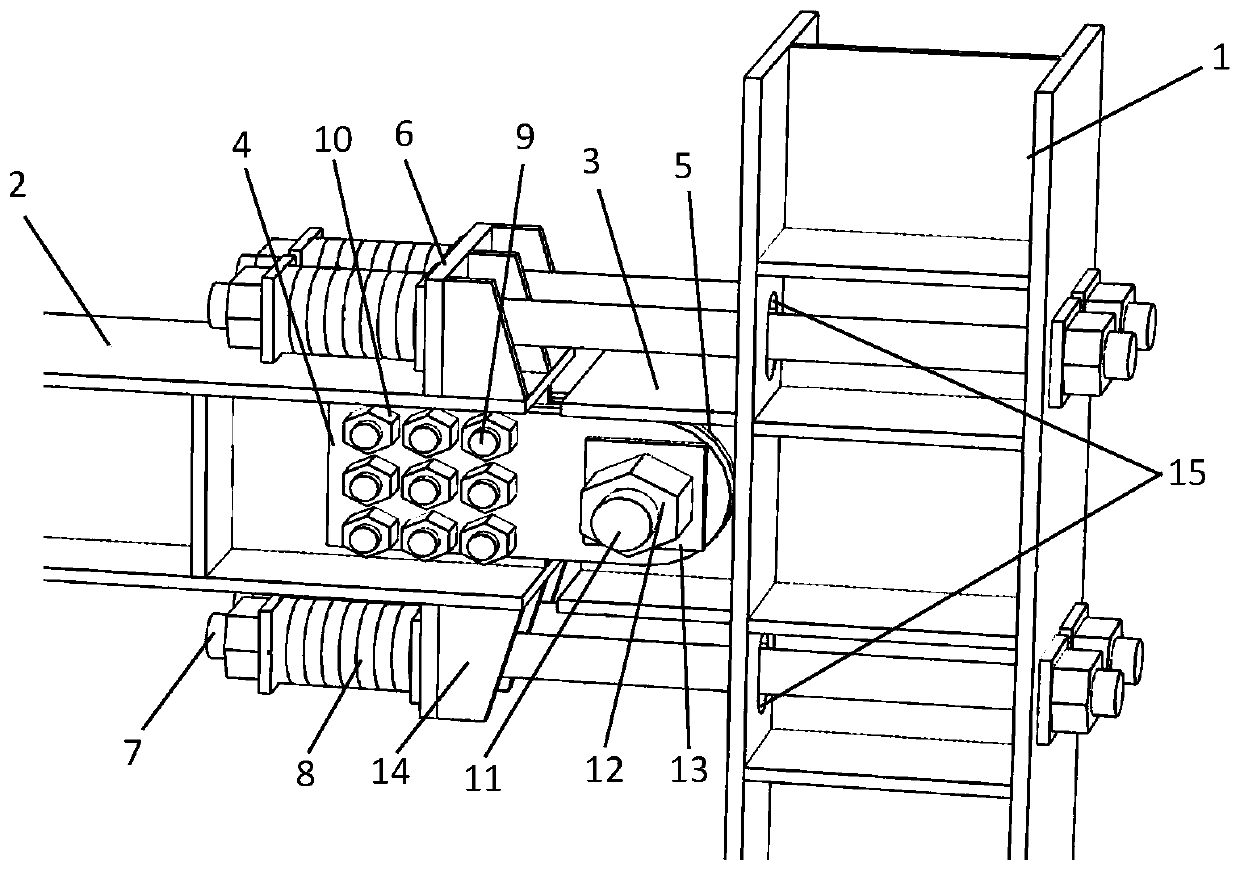

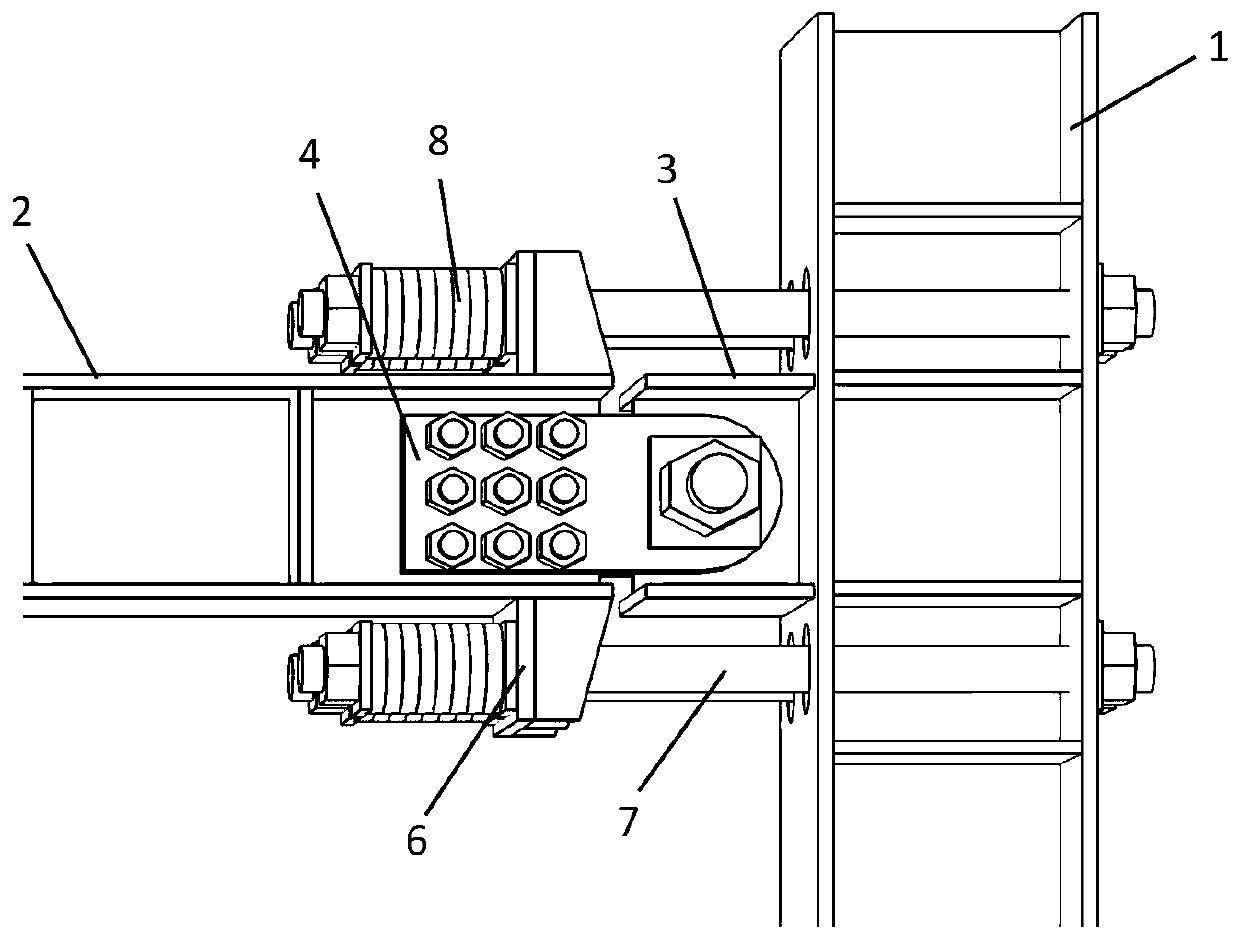

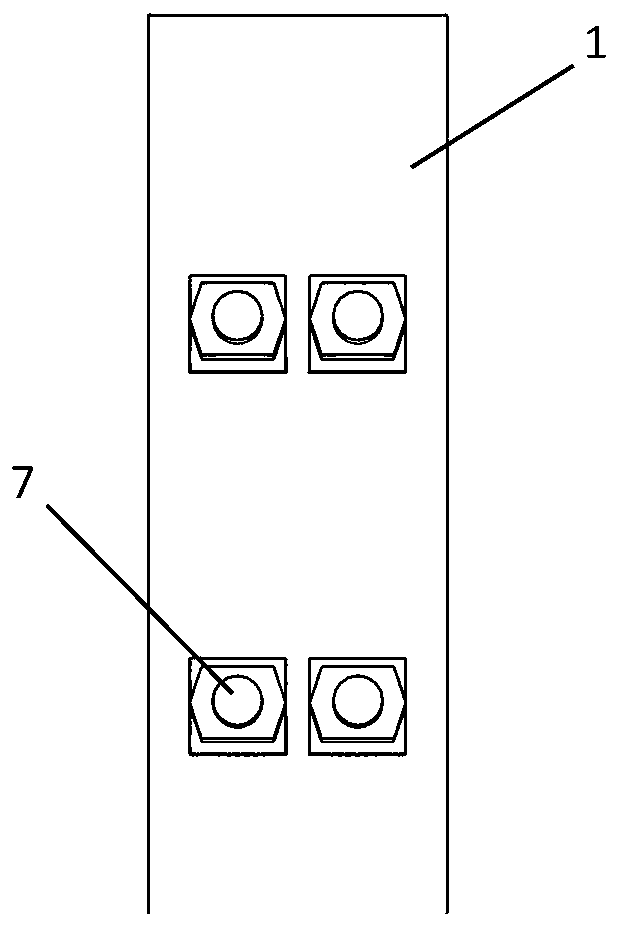

[0057] See attached figure 1 To attach Figure 4 , the embodiment of the present invention discloses a self-resetting beam-column friction energy-dissipating node structure, which is characterized in that it includes a steel column 1, an intermediate beam 2, a short beam 3, a connecting plate 4, a brass friction plate 5, and a spring baffle 6 , high-strength anchor rod 7 and disc spring 8;

[0058] The steel column 1 is arranged vertically, and the middle beam 2 is arranged horizontally;

[0059] The short beam 3 is located between the steel column 1 and the middle beam 2, one end of which is fixedly connected to the flange of the side wall of the steel column 1, and there is a gap between the middle beam 2 and the short beam 3;

[0060] One end of the connecting plate 4 is fixedly connected with the web of the intermediate beam 2, and the other end of the connecting plate 4 is hinged with the web of the short beam 3;

[0061] The brass friction plate 5 is arranged between ...

Embodiment 2

[0075] See attached Figure 5 , the embodiment of the present invention discloses a method for constructing a self-resetting beam-column frictional energy-dissipating node structure, which specifically includes the following steps:

[0076] S1. Foundation construction: Preliminarily determine the column network layout and beam-column dimensions of the frame where the node structure is located according to the functional requirements of the building structure, engineering geological conditions and conceptual design;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com