Steel beam and concrete wall semi-rigid full-bolted-connection joint

A technology for concrete walls and connecting nodes, which is applied in the direction of construction and building construction, can solve problems such as the inability to realize full bolt connection and the inability to realize the core tube wall sliding form process, so as to avoid on-site welding, improve structural rigidity, and achieve good results. Effects of Ductility and Dissipative Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

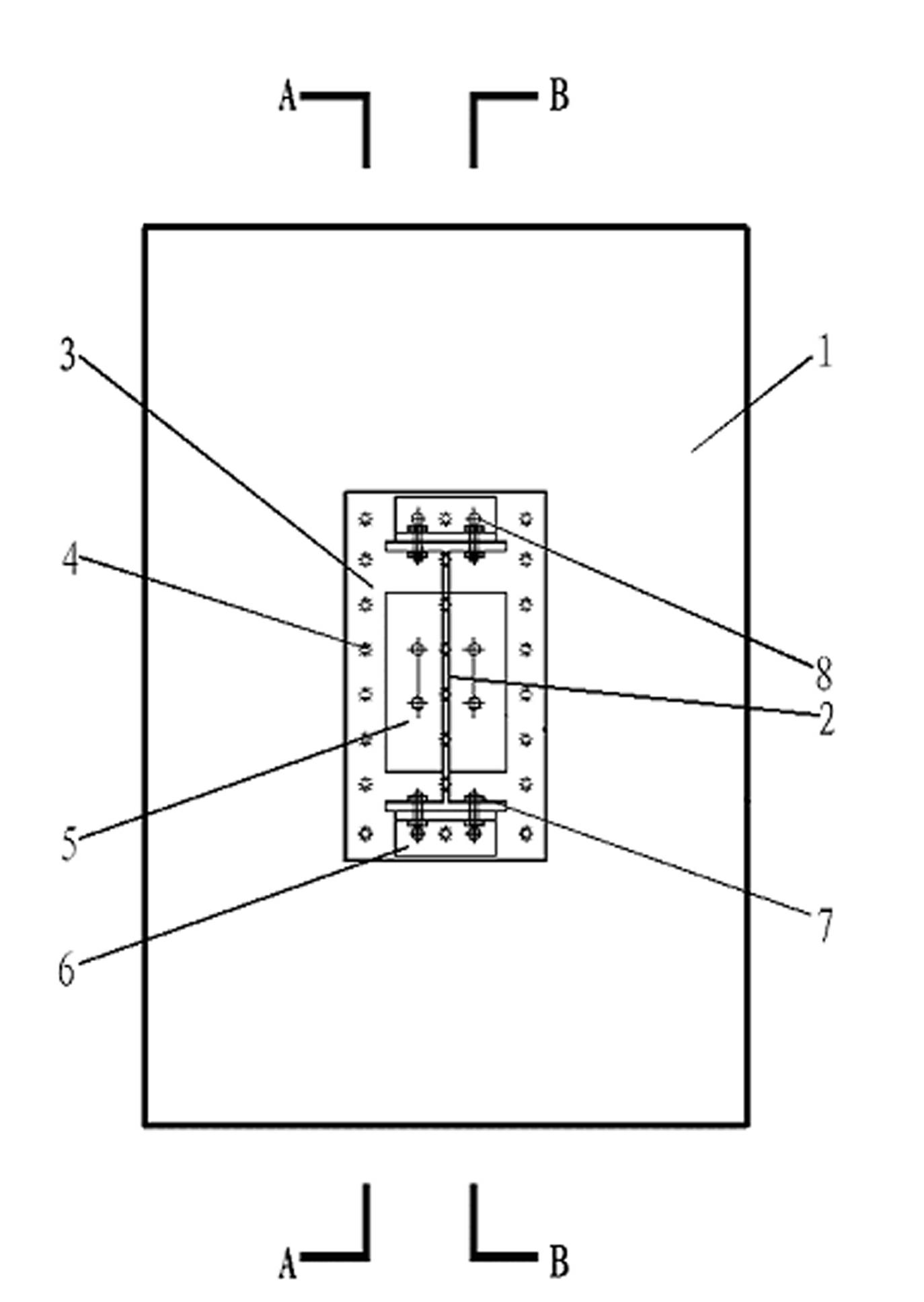

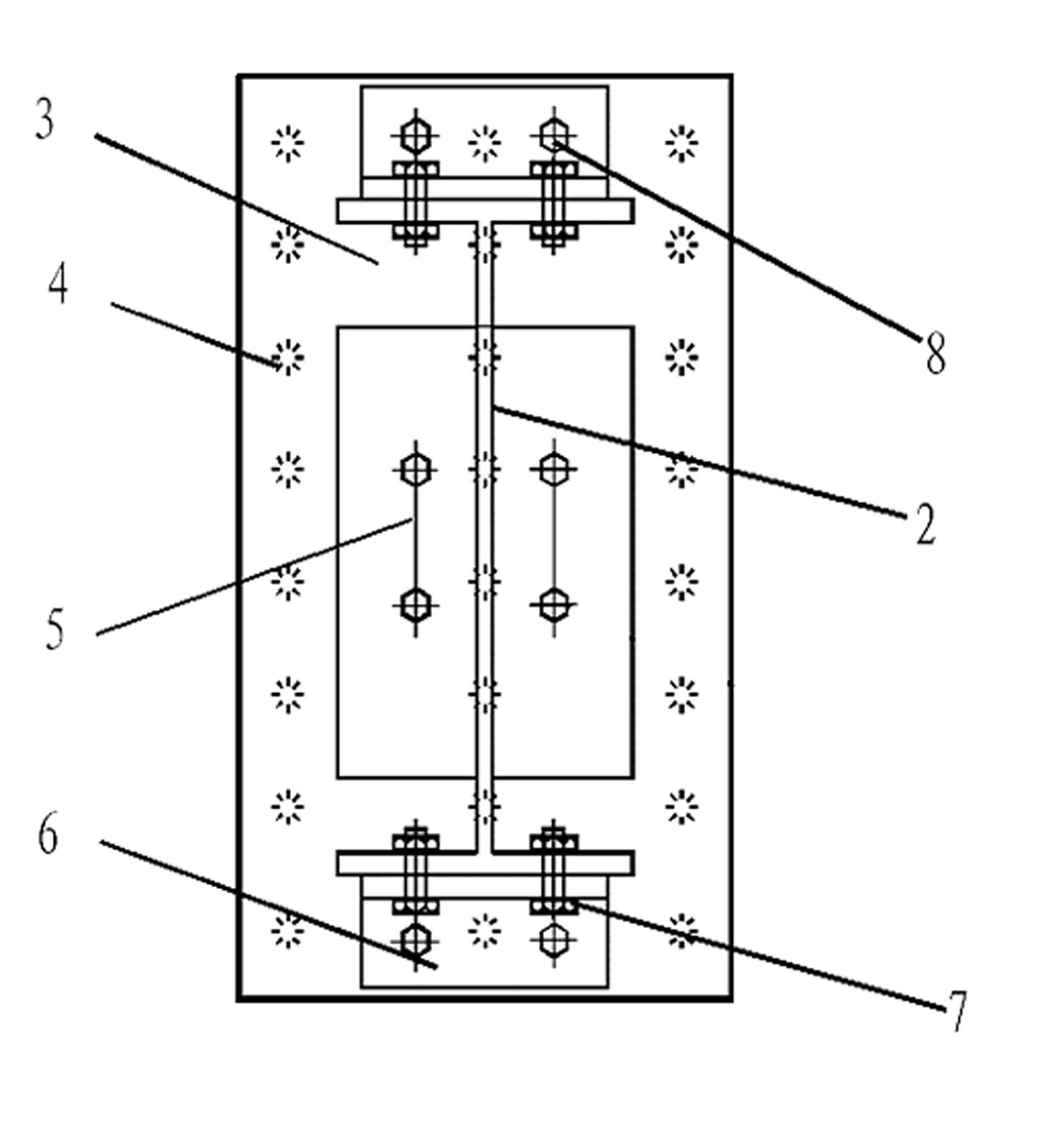

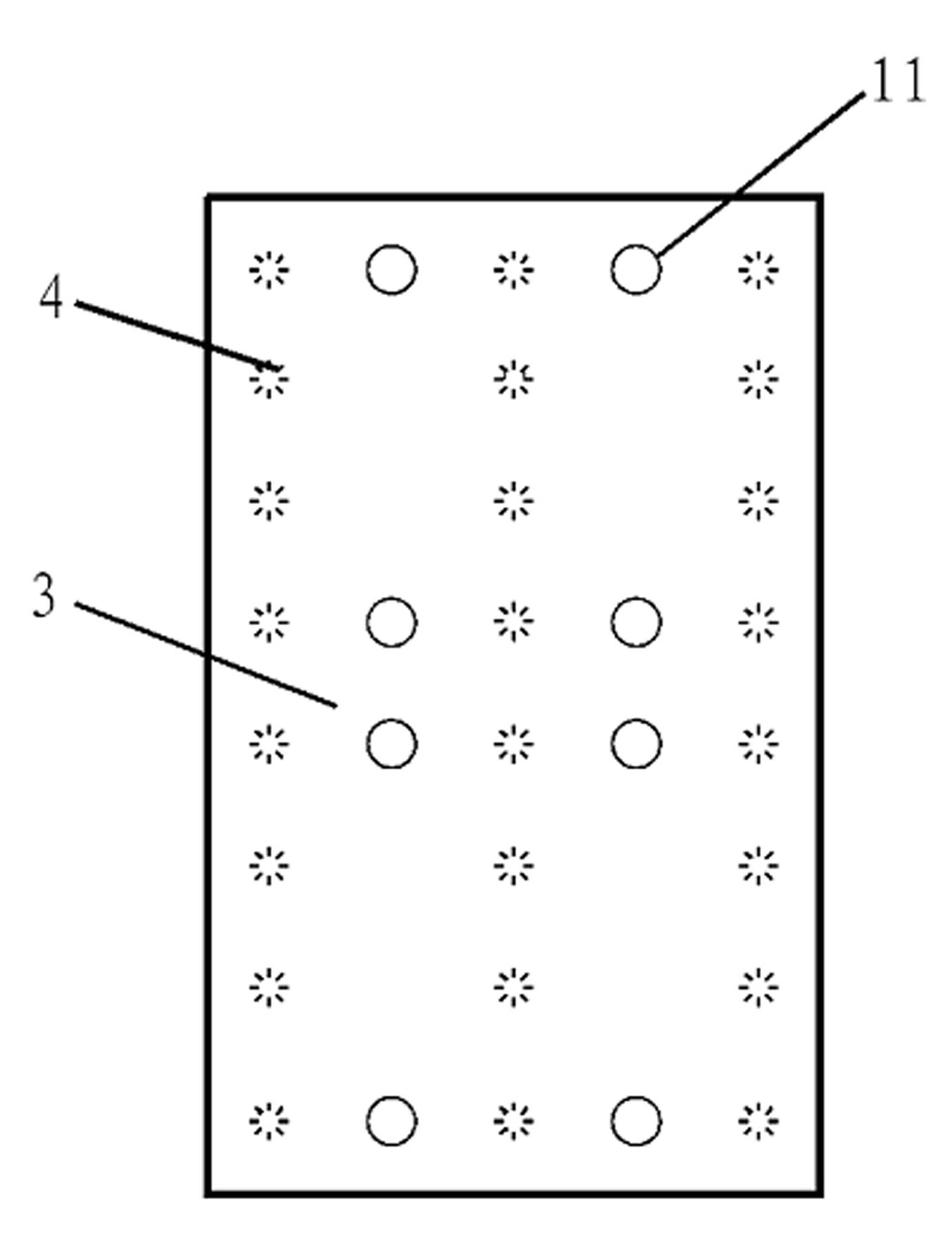

[0056] In order to better understand the present invention, a preferred embodiment of the steel beam-concrete wall semi-rigid fully bolted joint of the present invention will be described in detail below in conjunction with the accompanying drawings. The following description is only exemplary and explanatory, and should not be used for this There is no limitative effect on the scope of protection of the invention.

[0057] Steel beam-concrete wall semi-rigid full-bolt connection node, including reinforced concrete wall 1, H-shaped steel beam 2, web angle steel 5, upper and lower flange angle steel 6, bolt 7, and bolt 8. Among them, the reinforced concrete wall 1 has built-in special embedded parts, and the special embedded parts include steel plates 3, straight anchor bars 4, L-shaped anchor bars 12, and steel bar connectors 9.

[0058] Such as figure 1 and figure 2 As shown, the reinforced concrete wall 1 has built-in special embedded parts, the upper and lower flanges of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com