Composite external wall panel for hiding steel frame beam column

A composite exterior wall panel and steel frame technology, applied in the direction of load-bearing elongated structural members, columns, joists, etc., can solve the problems of limited thickness and weight of external wall panels, adverse effects of spatial regularity, etc. Achieve the effect of solving thickness and weight restrictions and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

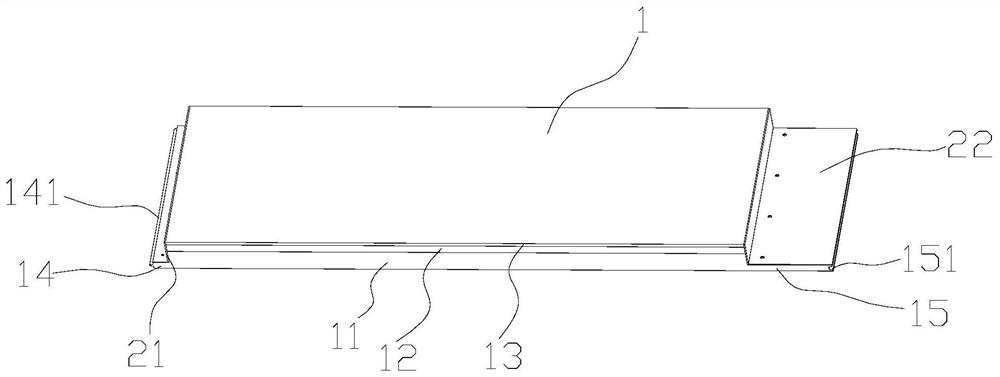

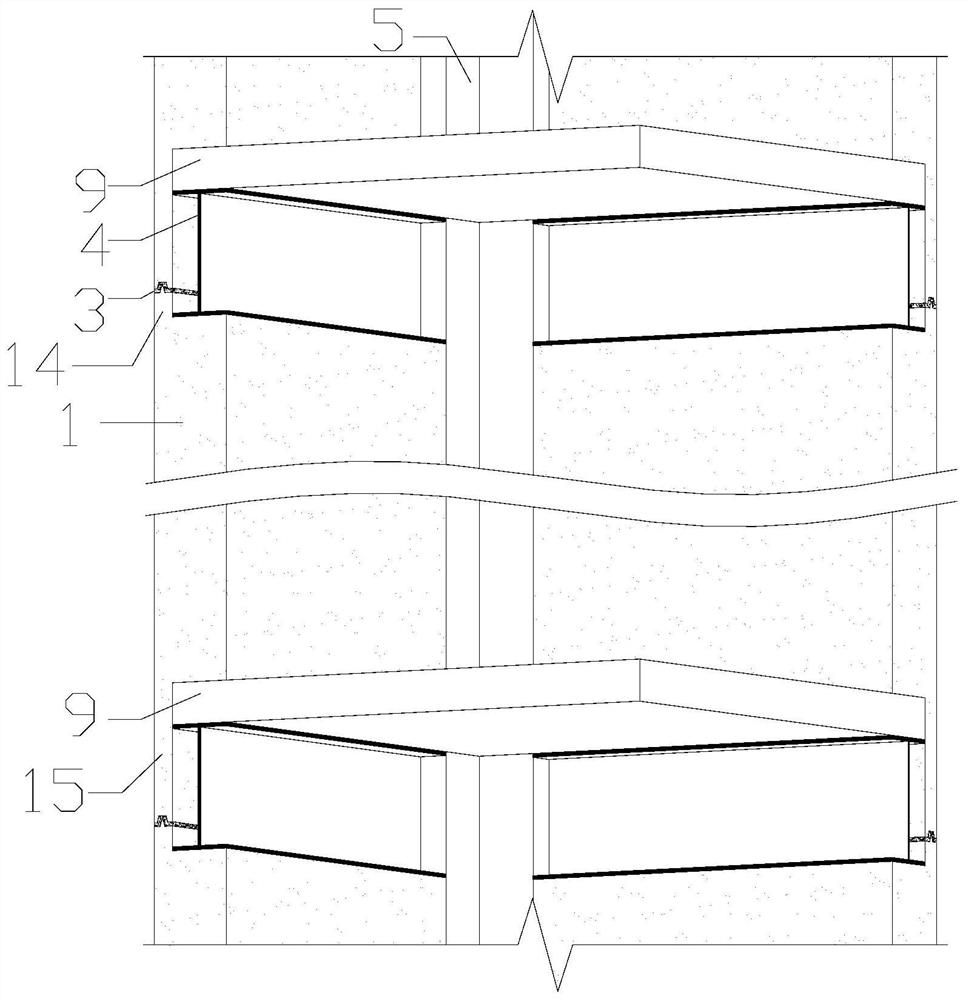

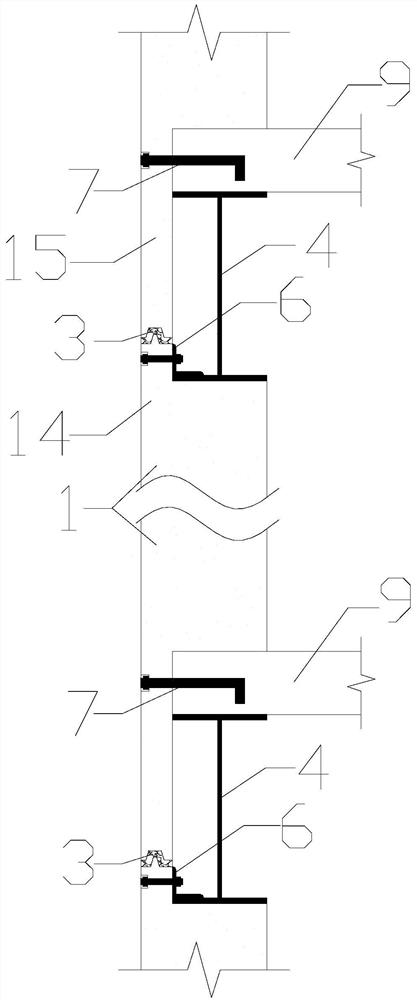

[0027] This embodiment provides a composite exterior wall panel for hiding steel frame beams and columns. The steel frame beams and columns include steel beams 4 and steel columns 5. The steel beams are I-shaped. beam connection.

[0028] The composite exterior wall panel includes the abdomen 1 and the splicing sections located at the upper and lower ends of the abdomen. The section thickness of the abdomen is greater than that of the splicing section. The upper end surface of the abdomen abuts against the bottom surface of the steel beam, and the lower end surface of the abdomen abuts against the top of the lower floor slab The upper and lower adjacent composite exterior wall panels are connected by a splicing section, the inner end surface of the abdomen is flush with the end surfaces of the steel beams and steel columns, the splicing section at the top of the composite exterior wall panel is connected with the steel beam, and the lower end of the composite exterior wall pane...

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is that, as Figure 4 As shown, the near column end of the abdomen extends vertically from the column end reinforcement section 16, the section thickness of the column end reinforcement section is smaller than the section thickness of the abdomen, the column end reinforcement section fits the side of the steel column, and the column end reinforcement section is preset Multiple bolt holes, multiple bolts 8 are pre-welded on the side of the steel column, the diameter of the bolts can be 10mm, and the spacing can be 300mm, arranged vertically along the steel column, and the bolts on the steel column pass through the bolt holes on the reinforcement section at the end of the column After being connected with the nut, the two sides of the reinforced L-shaped steel plate 23 are respectively connected to the column end reinforcement section and the abdomen, and the reinforced L-shaped steel plate is provided with bolt holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com