Rigid connection joint of steel-structure rectangular rod piece and processing and installation method thereof

A rigid connection and steel structure technology, applied in building structure, construction, etc., can solve problems such as inconsistency, affecting the installation of floor or wall panels, and difficult welding, etc., to achieve less time-consuming, lower construction difficulty, and lower labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

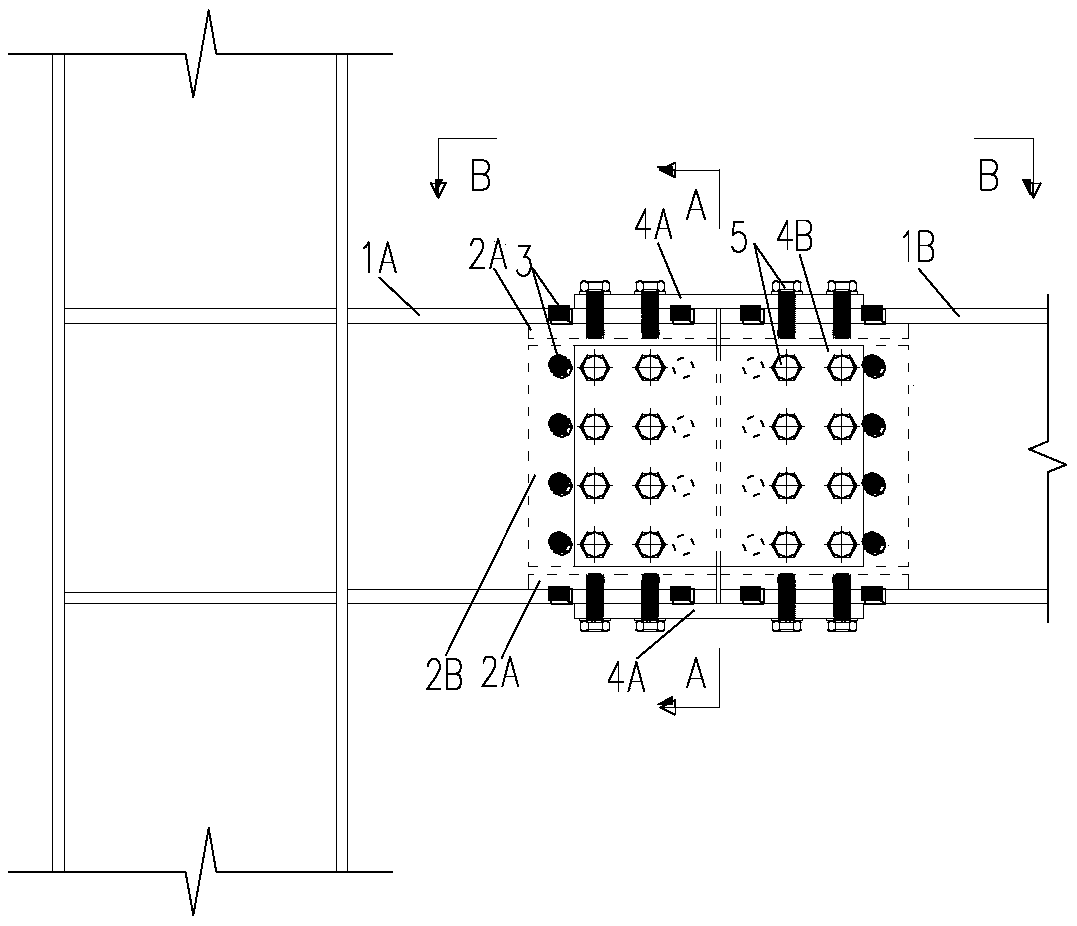

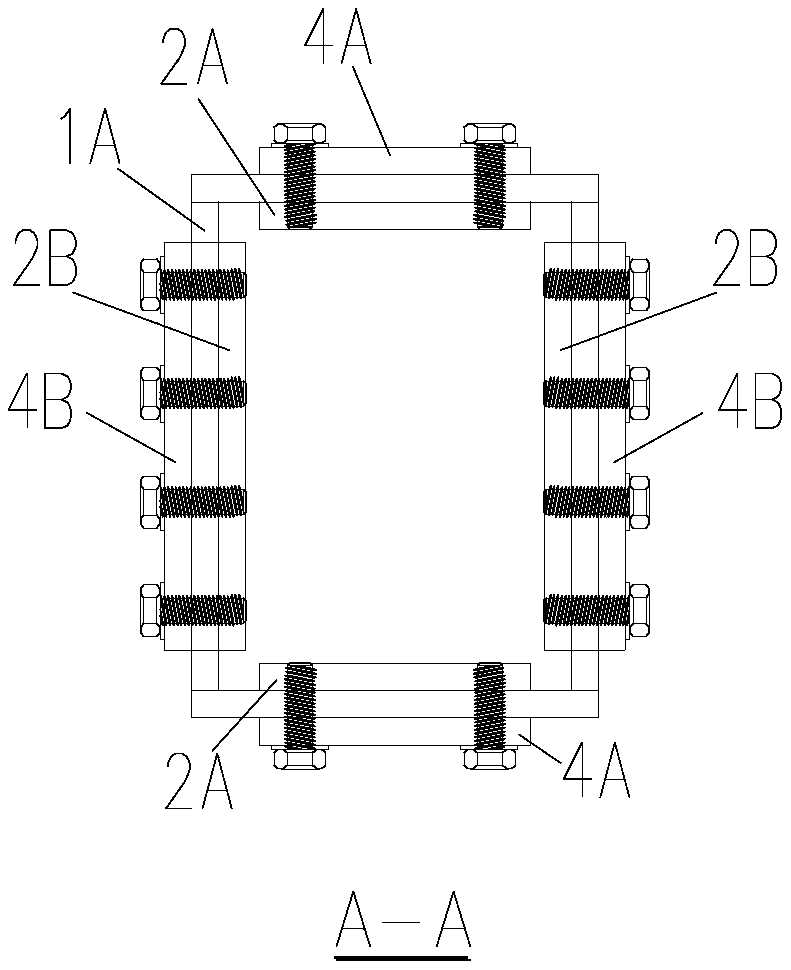

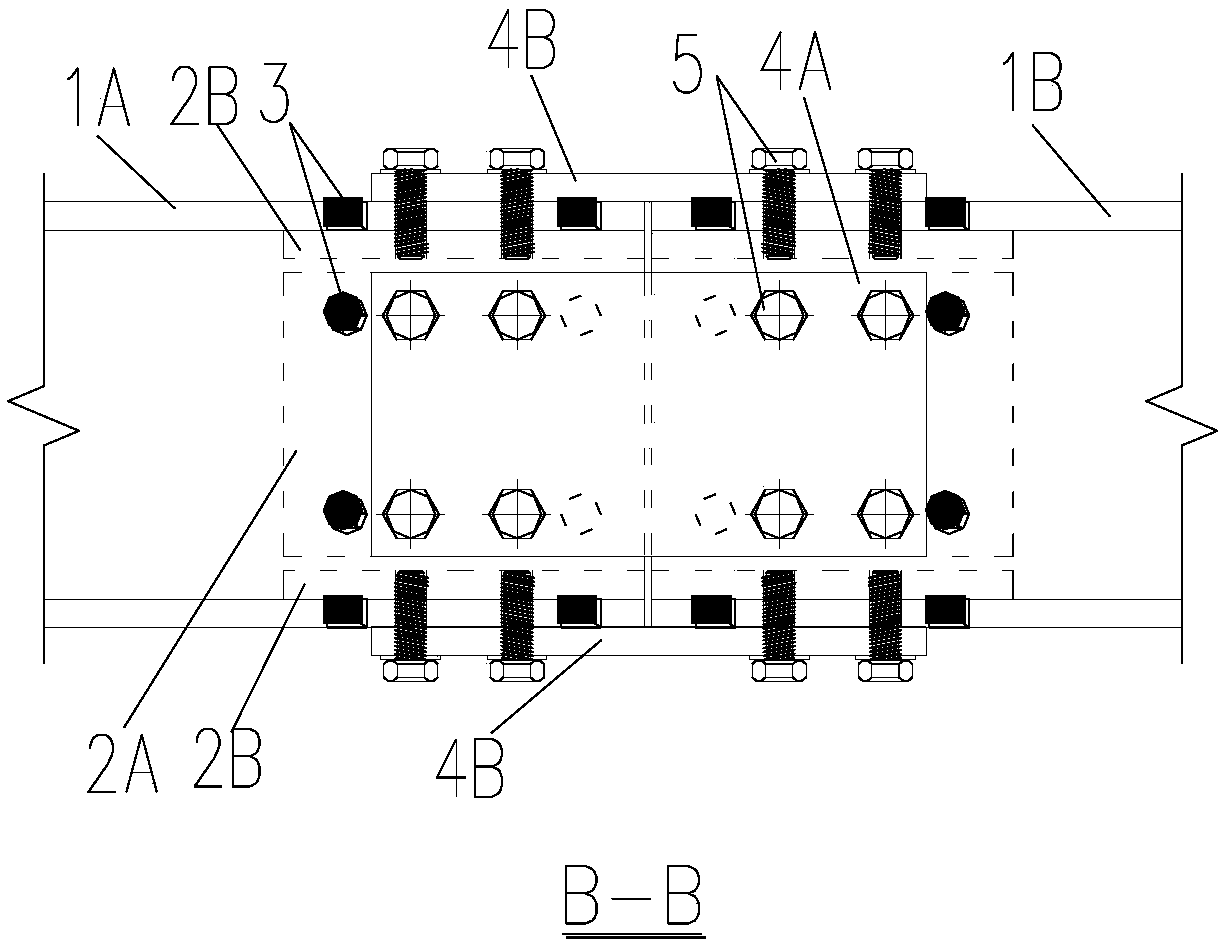

[0049] Such as Figure 1 to Figure 2 As shown, a rigid connection node of a steel structure rectangular member includes a first rectangular section steel member (steel column with a rectangular section corbel) 1A, a second rectangular section steel member (rectangular section steel Beam) 1B, four flange screw hole built-in plates 2A, four web screw hole built-in plates 2B, forty-eight plug welds 3, two flange connecting plates 4A, two web connecting plates 4B, forty-eight bolts 5. Its connection relationship is: drill 24 bolt holes and 24 plug welding holes on the flange and web plate of a first rectangular cross-section steel member 1A, the same. Twenty-four...

Embodiment 2

[0059] A factory processing method for a rigid connection node of a steel structure rectangular bar, the steps of which are:

[0060] (1) Drill bolt holes and plug welding holes on the first rectangular cross-section steel rod 1A and the second rectangular cross-section steel rod 1B according to the design drawing.

[0061] (2) According to the design drawing, drill and tap the steel plate that has been cut by numerical control to make the flange screw hole built-in plate 2A and the web screw hole built-in plate 2B.

[0062] (3) The built-in plate 2A of the flange screw hole and the built-in plate 2B of the web screw hole are built into the four sides of the first rectangular cross-section steel rod 1A and the second rectangular cross-section steel rod 1B. A plug weld connection is made between the two. Wherein, the screw holes of the flange screw hole built-in plate 2A and the web screw hole built-in plate 2B are concentric with the bolt holes on the first rectangular cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com