An air energy curing kiln

A curing kiln and air energy technology, which is applied in the field of curing kiln for concrete components, can solve the problems that it is difficult to ensure the temperature and humidity of prefabricated components, unfavorable for energy saving and environmental protection, and cumbersome management, so as to achieve superior thermal insulation performance, reduce heat storage and Effect of heat dissipation loss and energy waste avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

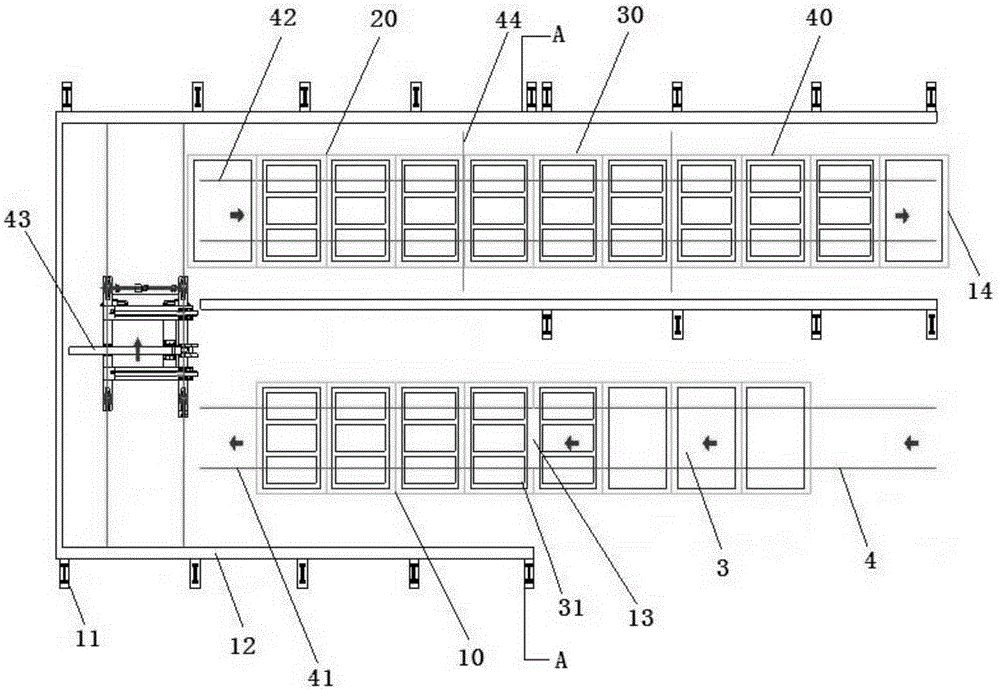

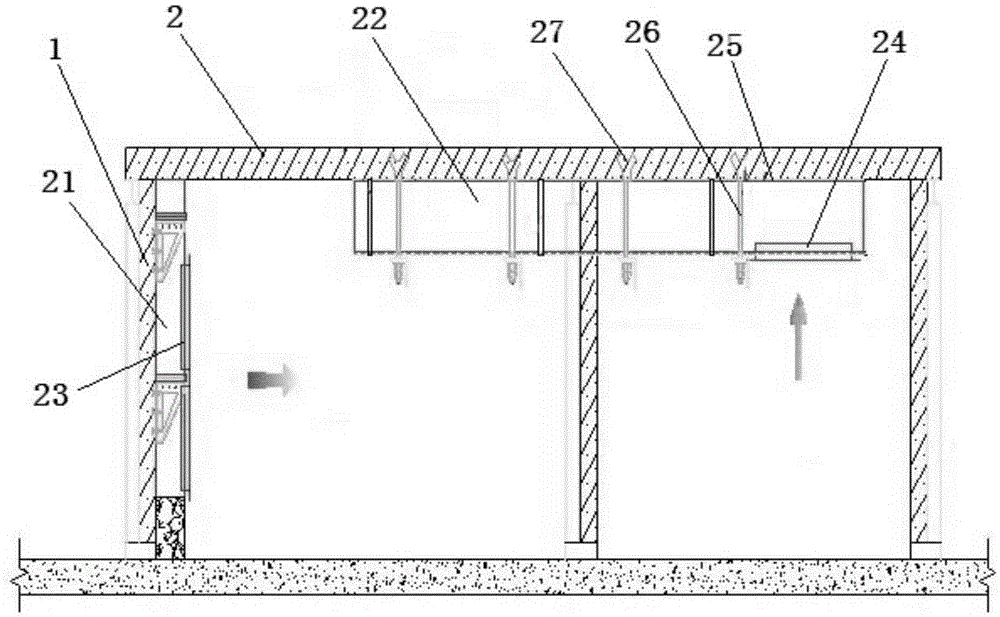

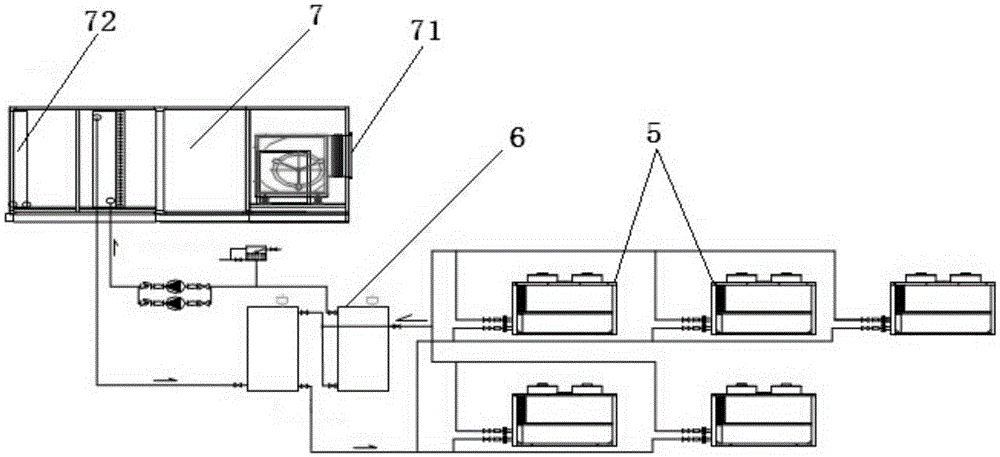

[0028] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, an air energy conservation kiln includes a kiln body, a hot air pipe installed in the kiln, and an air source high-temperature heat pump constant temperature system that provides a heat source for the kiln.

[0030] Wherein, the kiln body includes a wall 1 and a kiln roof 2, the wall includes an H-shaped steel external frame 11 and an ALC partition board 12 connected to the H-shaped steel external frame 11, and the kiln roof 2 adopts ALC The roof panel is sealed with the wall 1; the kiln body is provided with an inlet 13 and an outlet 14, and the kiln body inlet 13 and outlet 14 are both provided with automatic doors.

[0031] The inside of the kiln is divided into four temperature sections according to the temperature, which are respectively a preheating zone 10, a heating zone 20, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com