Fabricated FRP concrete combined guy rope tower type lining foundation platform and construction method thereof

A basic platform and construction method technology, applied in the direction of infrastructure engineering, artificial islands, water conservancy projects, etc., can solve the problems of no large-scale application, high cost and construction cost, etc., achieve improved capacity, improved deformation performance, and time-consuming short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

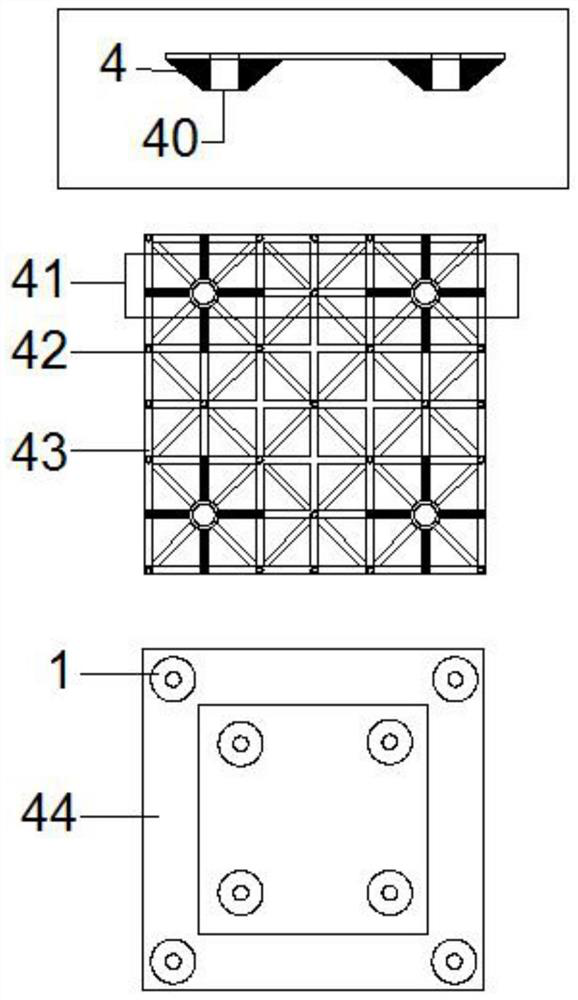

[0052] Such as Figure 9 , Figure 10 As shown, the prefabricated FRP concrete composite guy tower lining foundation platform structure system is composed of prefabricated FRP concrete composite columns, FRP concrete composite trusses, and FRP integral multi-plane nodes. , vertical half-pipe, and oblique half-pipe intersect to form connecting lugs with bolt holes; the ends of FRP concrete composite columns and FRP concrete composite trusses form connecting lugs with bolt holes. After the pipe passes through the ring damper, it is embedded in the node half pipe and fixed by high-strength bolt connection. Such as figure 2 In , the component nodes of the superstructure truss platform are combined in the above-mentioned way.

[0053] Construction method in this embodiment:

[0054] The construction method of prefabricated integral multi-plane joints, firstly design multi-plane joints according to the design requirements, and wrap the outer wall of multi-plane joints with seam...

Embodiment 2

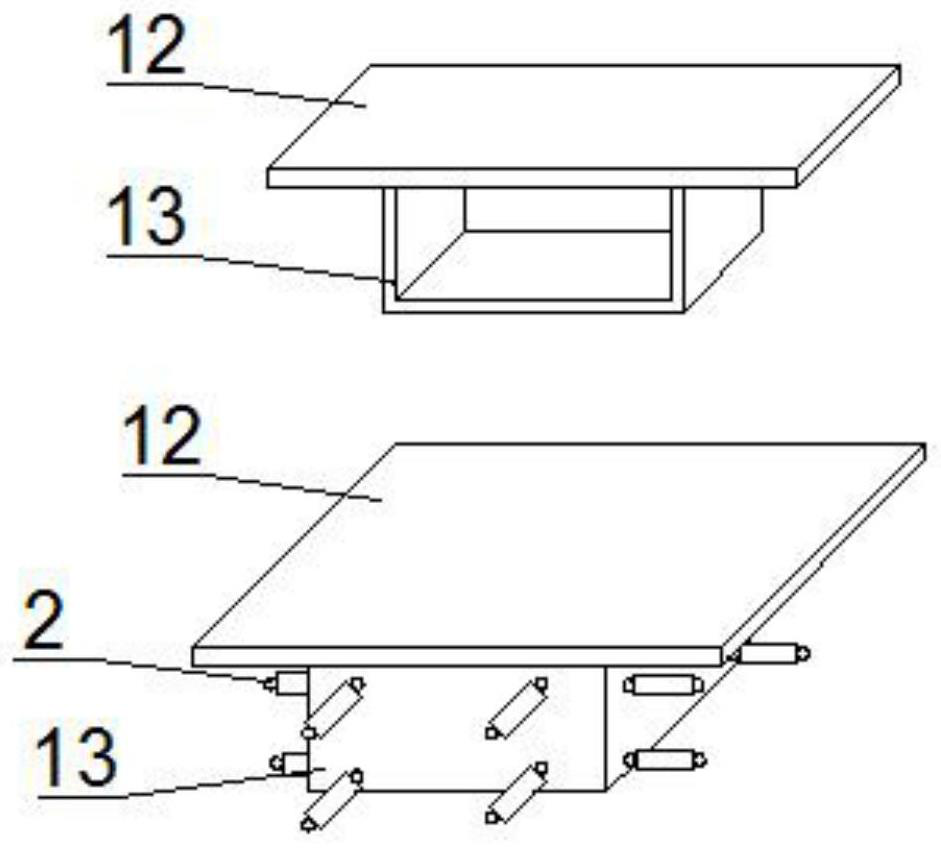

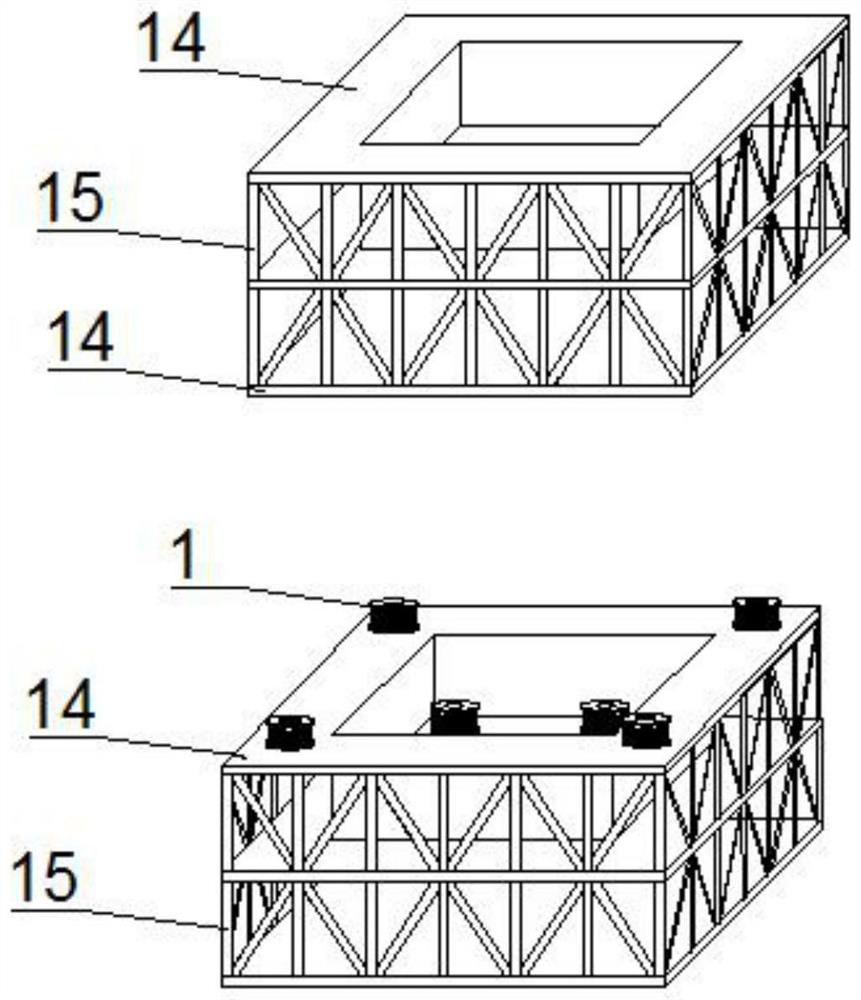

[0058] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the truss platform of the upper structure of the prefabricated FRP combined guy cable tower damping platform structure is composed of prefabricated FRP concrete trusses, FRP concrete columns inserted into ring dampers, and connected to FRP integral multi-plane nodes. The connection is fixed to form a truss platform structure; the lower part of the truss platform is welded to the column leg connection according to the design requirements; wherein, the upper structure-lower structure connection part is composed of column leg connection, stiffeners, connecting ears, and inner pipes, which are nested with inner pipes connected by means of vertical high-strength bolts, and then fixed by longitudinal high-strength bolts; the shock-absorbing box structure of the upper structure is welded into an integrated box by steel plates, and high-strength bolt holes are arranged at the connection position of the...

Embodiment 3

[0060] Such as Figure 6 , Figure 7 As shown, the lower truss structure is composed of multiple truss layered modules, in which 5 to 6 basic truss units are connected to form a layered module monomer with a height of 30 meters; C-type sleeve 1, C-type sleeve 2, rubber gasket, FRP concrete inner tube with cone head, high-strength bolts, C-type sleeve 1, C-type sleeve 2 are respectively welded and fixed to both ends of the column of the upper and lower trusses , The side wall of the upper truss column is equipped with a hydraulic retainer, the bottom is welded with an FRP inner tube with a cone head, and the top of the lower truss column is equipped with a rubber gasket.

[0061] Construction method in this embodiment:

[0062] First, the factory prefabricated FRP concrete trusses and FRP concrete columns are inserted into the ring damper, connected to the FRP integral multi-plane nodes, connected and fixed by high-strength bolts to form a unit truss structure, and a tower st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com