Beam-column joint connecting device for multi-story/high-rise assembly type steel structure system

A connecting device and beam-column joint technology, which is applied in the direction of building structure and construction, can solve the problems of poor ductility of joints, influence on construction speed and quality, and complicated construction procedures, so as to protect joints, improve assembly speed and quality, and facilitate The effect of worker operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

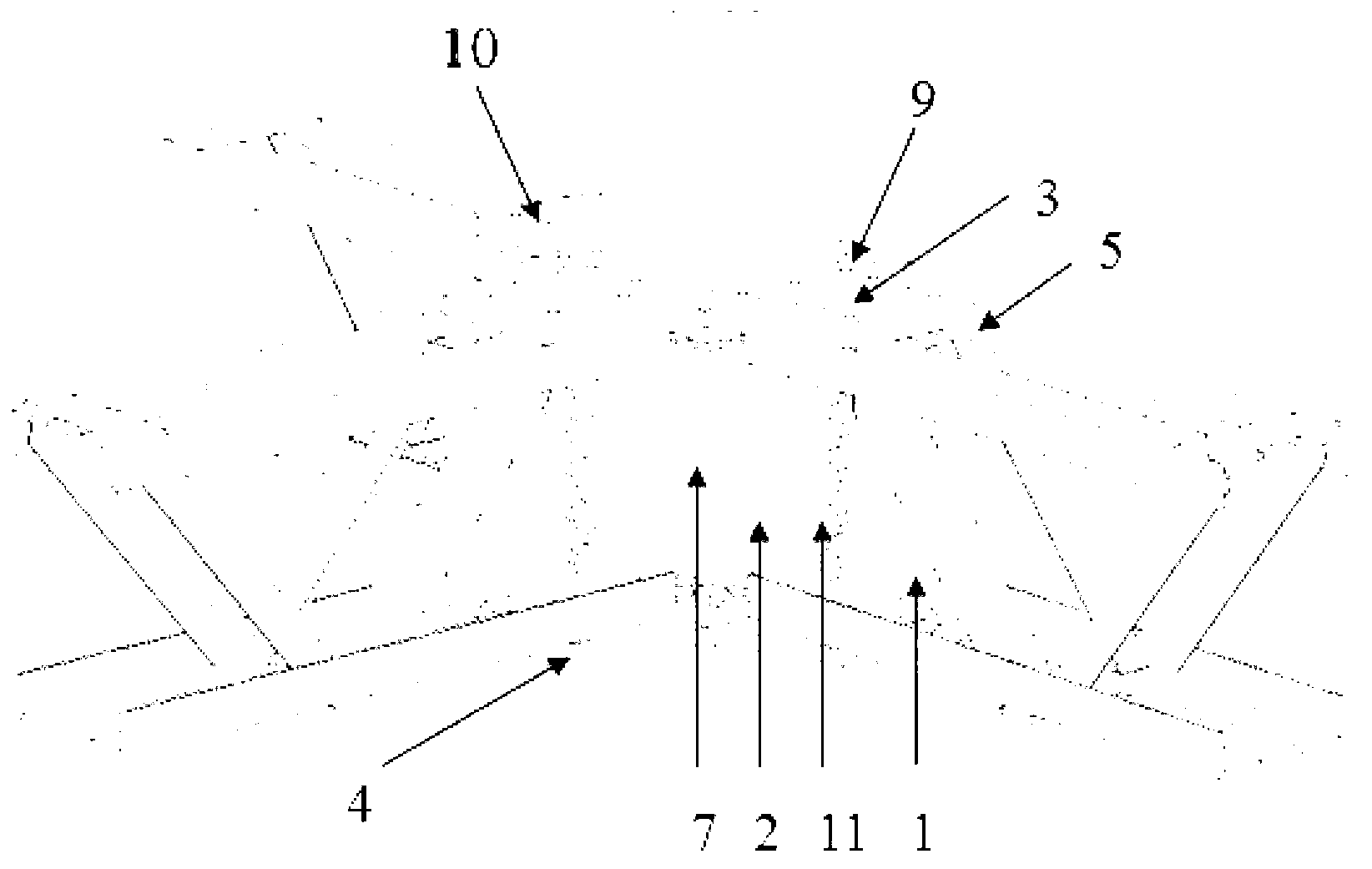

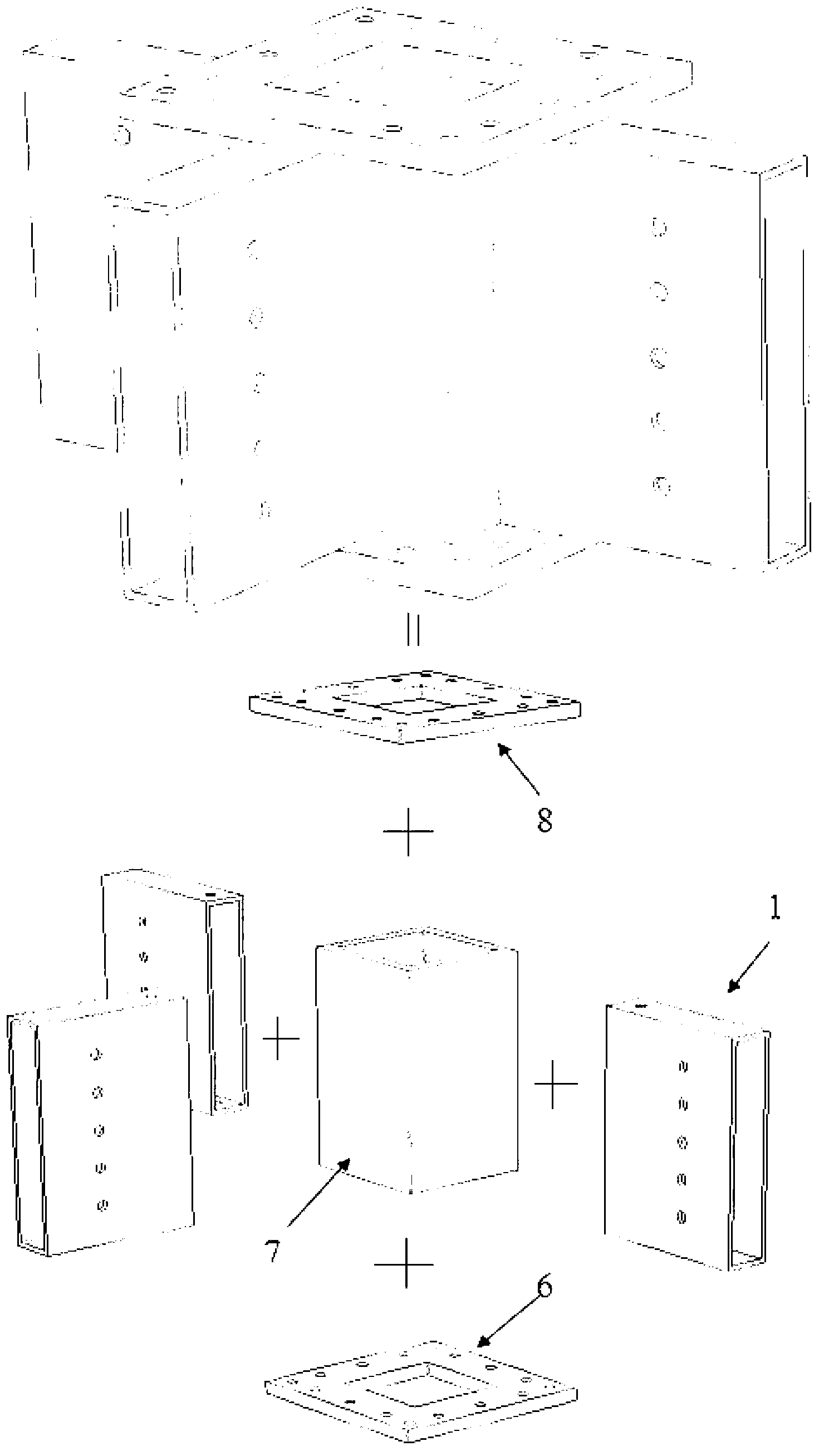

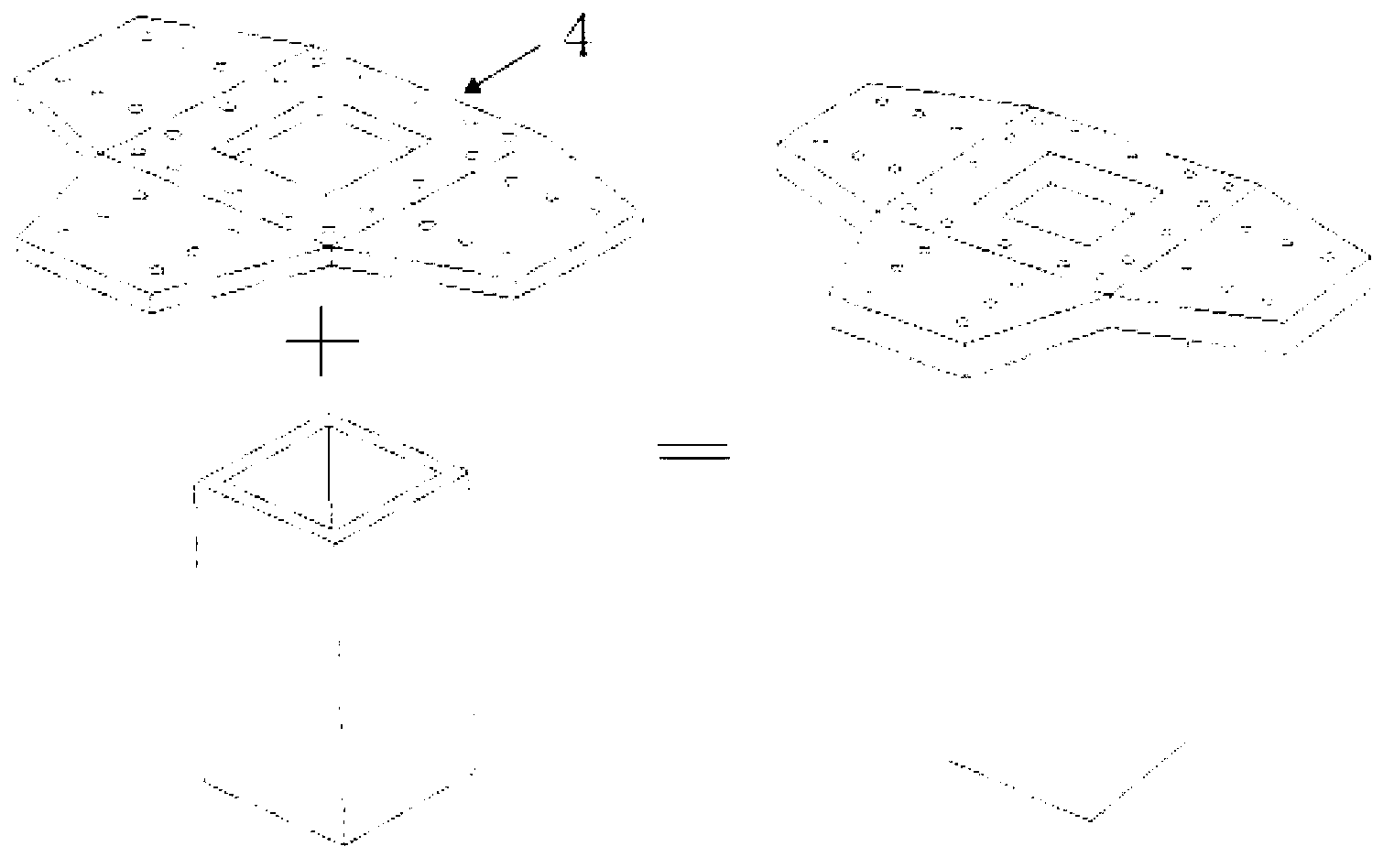

[0027] The specific connection mode of the beam-column node of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] as attached Figure 1-7 As shown, a beam-column node connection device of a multi-high-rise assembled steel structure system of the present invention includes node short columns 7, beam end box-type connectors 1, truss beam end upper and lower chords 5, vertical connecting channel steel 2. Upper column flange 3, lower column flange 4, node stub upper end flange 8, node stub lower end flange 6. The upper flange 8 of the node stub and the lower flange 6 of the node stub are respectively welded to the upper and lower ends of the node stub 7; the upper flange 8 of the node stub and the upper flange 3 are connected by bolts 9, and the node stub The lower end flange 6 and the lower column flange 4 are connected by bolts 9; the beam-end box-shaped connector 1 is welded to the outer surface of the node short col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com