Double-layer steel sheet pile soil core composite cofferdam structure without inner support and application thereof

A technology of combining cofferdams and steel sheet piles, applied in infrastructure engineering, construction, etc., can solve problems such as instability and damage, water seepage, and large deformation of steel sheet piles, so as to enhance stability, improve impermeability, and improve overall stability. Effects of Sex and Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

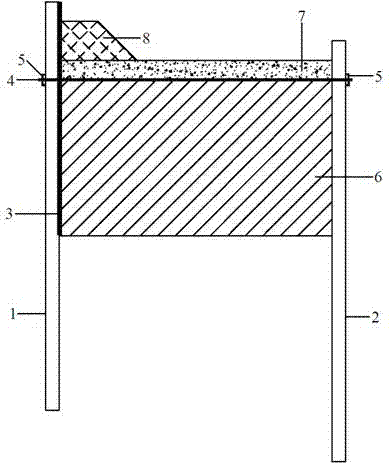

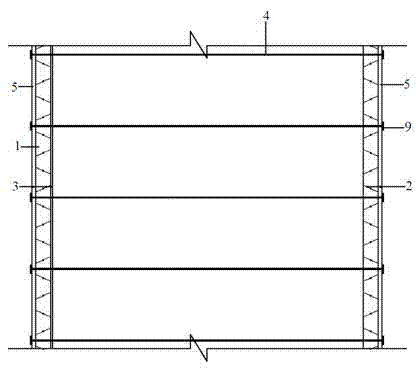

[0024] A composite cofferdam structure with double-layer steel sheet pile soil core without internal support, its schematic diagram is as follows figure 1 with 2 As shown, including steel sheet pile 1 on the upstream surface and steel sheet pile 2 on the rear surface (steel sheet piles on the upstream surface and steel sheet pile 2 on the rear surface are formed by interlocking the steel sheet piles through locks), and the filling between the steel sheet piles (1 and 2) Cohesive soil forms a cofferdam. A composite geomembrane 3 is laid on the inner side of the steel sheet pile 1 cofferdam on the water-facing surface to prevent seepage and water. The upper part between the two steel sheet piles (1 and 2) is connected by tie rod 4, and the outer side of the steel sheet pile (1 and 2) is provided with a waist beam 5, and the tie rod 4 is connected through the waist beam 5 by bolts 9, and the bolt 9 is arranged on the outer side of the waist beam 5 . After the cohesive soil 6 i...

Embodiment 2

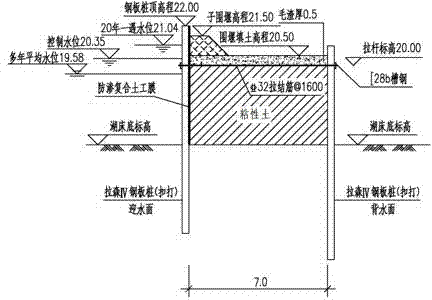

[0027] The double-layer steel sheet pile soil core composite cofferdam structure without internal support is firstly laid with Larsen IV-type steel sheet piles on both sides. The embedded depth of the steel sheet piles is controlled according to the elevation of the pile tops, and each row of steel sheet piles is locked and connected. After the construction of the steel sheet piles on both sides, the waterproof geomembrane of the steel sheet piles on the water-facing surface will be hung, and the geomembrane will use bagged soil for the bottom presser foot. Then carry out the construction of steel sheet pile waist beams and tie rods on both sides. The waist beams are set on the outside of the steel sheet piles. The tie rods are connected horizontally with 32 threaded steel along the direction of the cofferdam at a distance of 1.6m. The outer sides are made of 28b channel steel waist beams. Holes need to be drilled with the waist beam, and bolts are used to connect the tie rod a...

Embodiment 3

[0029] The composite cofferdam structure of double-layer steel sheet pile soil core without internal support is applied to the construction of Wuhan East Lake Channel Project. The Donghu Passage project is planned to start from the Hongmiao Interchange of the Second Ring Road in the north and connect with the Shuidong Section of the Second Ring Road in the north, and end at the intersection of Yujiahu Road and Yujiashan North Road in the south. The total length is about 10.6 kilometers, of which the length of the tunnel in the lake is about 4.94 kilometers. The middle section of the tunnel lake adopts two structural forms of steel sheet pile cofferdam and soil cofferdam. The total cofferdam length on one side of the project is about 8.05 kilometers, of which the length of the steel sheet pile cofferdam without internal support is about 7.36 kilometers, and the total area of the cofferdam is about 550,000 m 2 , the distance between the cofferdam and the outer edge of the tunn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com