Large autoclaved lightweight aerated concrete slab and installation method thereof

A kind of air-entrained concrete, light-weight technology, applied to building components, building insulation materials, walls, etc., can solve the problems of cumbersome and complicated operations, heavy labor load, etc., achieve large external wall area, improve work efficiency, and reduce high-altitude operations volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

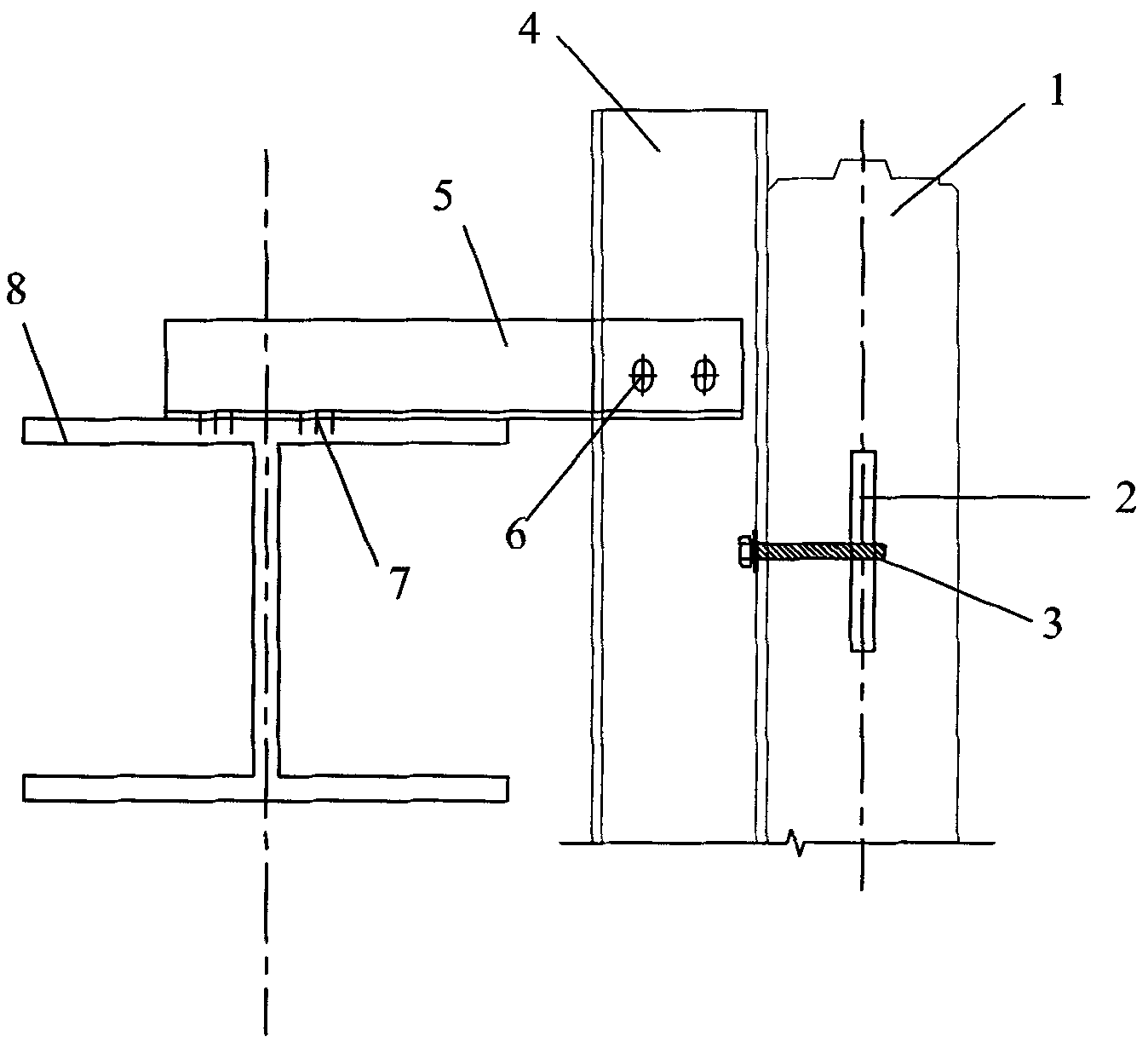

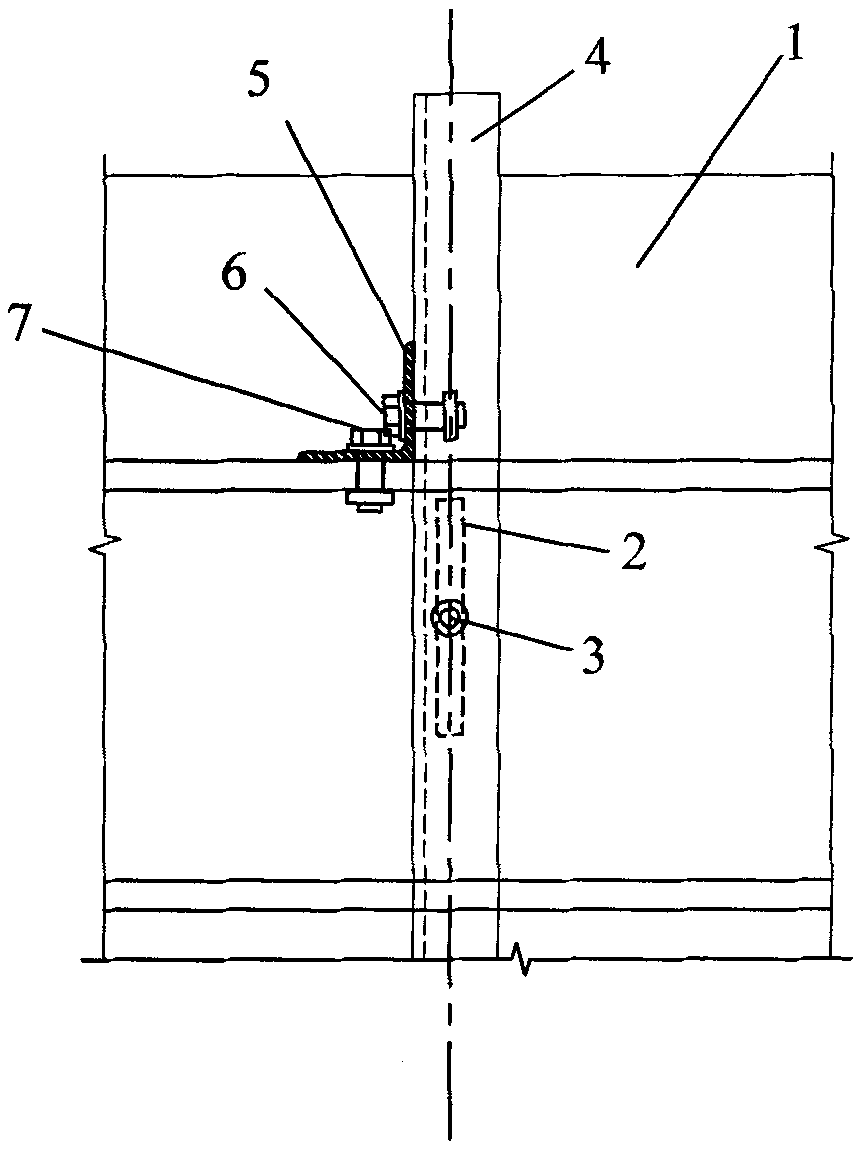

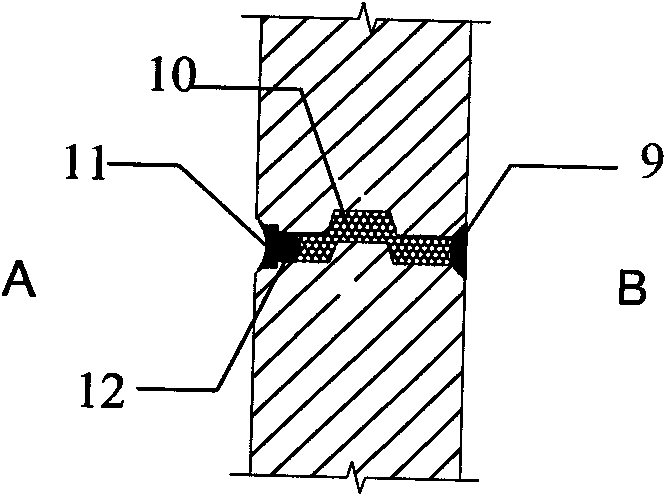

[0024] Such as figure 1 , figure 2 Shown is a longitudinal section view and a transverse section view of the connection between the autoclaved lightweight aerated concrete slab and the main steel structure of the present invention. The autoclaved lightweight aerated concrete slab 1 is connected to the channel steel 4 through the connecting rod 2 and the bolt 3, the channel steel 4 is connected to the main steel structure 8 through the angle steel 5, and the channel steel 4 and the angle steel 5 are connected through several bolts 6 Fixed, the angle steel 5 and the main steel structure 8 are fixed by bolts 7. Such as image 3 As shown, it is the cross-sectional view of the repaired slab gap formed between adjacent autoclaved lightweight aerated concrete slabs. A in the figure represents the outer side of the autoclaved lightweight aerated concrete slab, and B represents ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com