Adjustable fabricated jig frame for steel structure assembling and using method of adjustable fabricated jig frame

A steel structure and assembly technology, applied in building construction, building material processing, construction, etc., can solve the problems of not being fully utilized, large geometric dimensions of tire frame, poor mobility, etc., to avoid uneven settlement, The effect of high overall rigidity and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated below by specific examples.

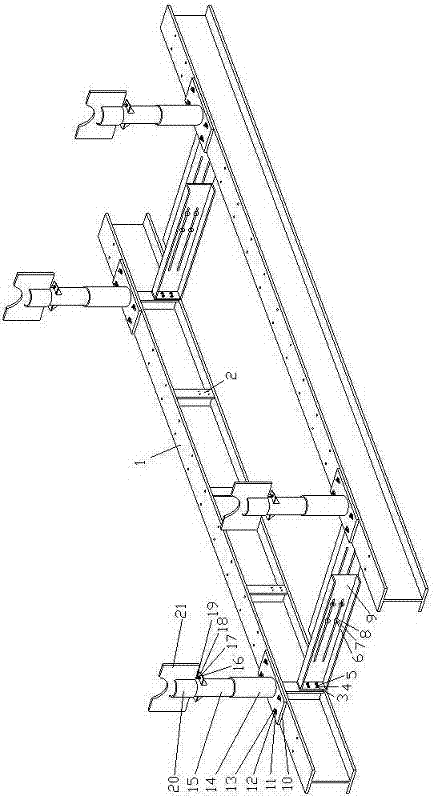

[0028] As shown in Figure 1, a tire frame for steel structure assembly is composed of a base part and a support part. The base part includes the base main beam 1 and the base tie beam 9, the base main beam 1 is made of H-shaped steel, and the base tie beam 9 is made of channel steel;

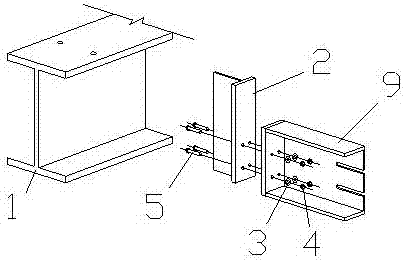

[0029] Such as figure 2 As shown, the T-shaped stiffening plate 2 is connected to the base main beam 1 by welding, and the base tie beam 9 is vertically connected to the T-shaped stiffening plate 2 through four sets of nuts 4, nut washers 3 and screw rods 5;

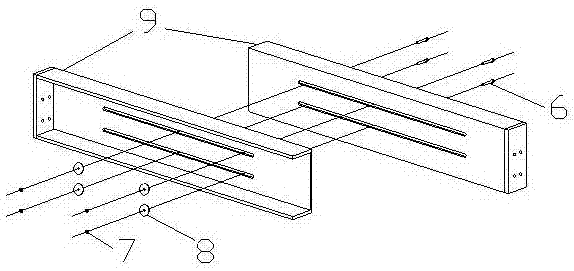

[0030] Such as image 3 As shown, the base tie beam 9 is divided into two sections, and the web directions are opposite, connected by four sets of nuts 7, nut gaskets 8 and screw rods 6;

[0031] Such as Figure 4 As shown, the supporting part includes a supporting base plate 10, a bottom circular tube 14, a supporting circular tube 15, a corbel 16, nuts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com