Angle-adjustable fan-shaped lead viscoelastic corner damper

A viscoelastic and adjustable technology, applied in building components, shockproof and other directions, can solve the problems of high cost, small yield displacement, inability to meet installation, etc., and achieve the effect of convenient angle adjustment, wide adjustment range and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

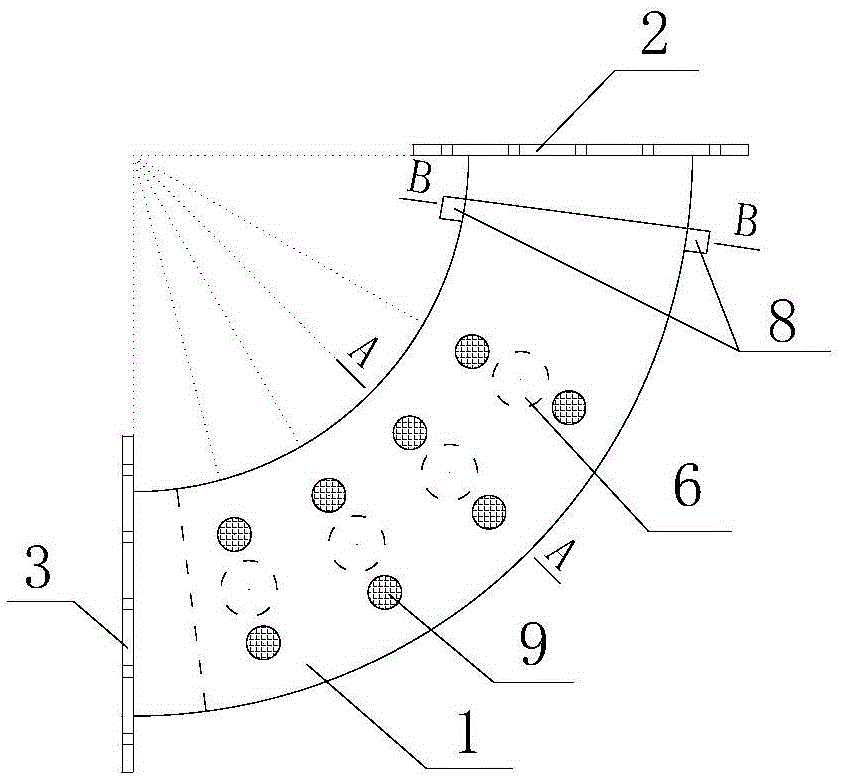

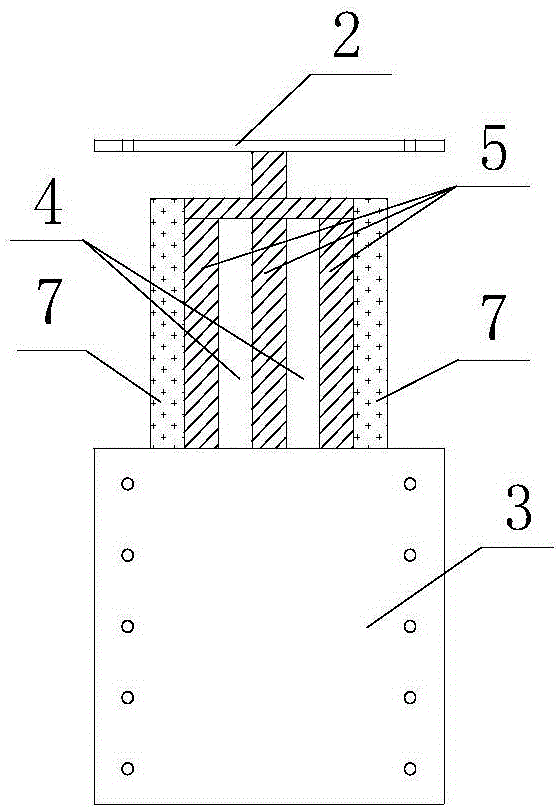

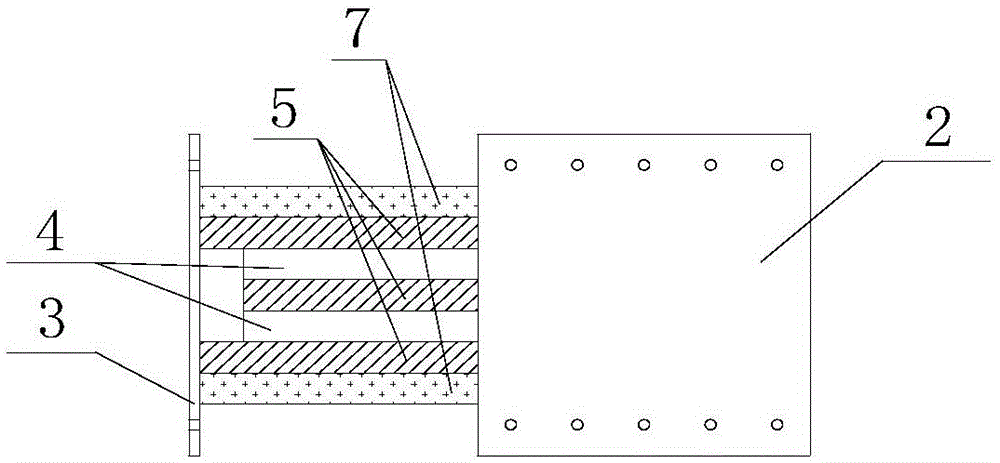

[0028] Such as Figure 1-4 As shown, the composite elastic body 1 is composed of two elastic bodies 4, three shear steel plates 5, four columnar lead cores 6 and two angle adjustment steel plates 7, and the angle adjustment steel plates 7 and the shear steel plates 5 are connected by bolts 9 For connection, the middle shear steel plate 5 is extended and welded to the first connecting plate 2, and the two angle-adjusting steel plates 7 are extended to the other end and welded and fixed to the second connecting plate 3.

[0029] Four columnar lead cores 6 respectively traverse two elastic bodies 4 and three shear steel plates 5 and are distributed along the arc length direction of composite elastic body 1; the center of circle of bolt 9 and the circle center of columnar lead core 6 are located on the same radius, equidistant Distributed on both sides of the columnar lead core 6, there are four groups of bolts 9, eight on each side and sixteen in total. The center angle between ...

Embodiment 2

[0038] Such as Figure 10 As shown, the composite elastic body 1 is composed of four elastic bodies 4, five shear steel plates 5, four columnar lead cores 6 and two angle adjustment steel plates 7, and the angle adjustment steel plates 7 and the shear steel plates 5 are connected by bolts 9 For connection, the three middle shear steel plates 5 are extended and fixed by welding with the first connecting plate 2 , and the two angle-adjusting steel plates 7 are extended to the other end and welded and fixed with the second connecting plate 3 .

[0039] The middle three shear steel plates 5 and the four elastic bodies 4 are pierced with through holes, the outer two shear steel plates 5 are pierced with blind holes, and the columnar lead core 6 passes through the through holes and passes through the blind holes on the outer shear steel plates 5 embedded solid.

[0040] Others are the same as embodiment one.

Embodiment 3

[0042] Such as Figure 11 As shown, the composite elastic body 1 is composed of two elastic bodies 4, three shear steel plates 5, two columnar lead cores 6 and two angle adjustment steel plates 7, and the angle adjustment steel plates 7 and the shear steel plates 5 are connected by bolts 9 The middle shearing steel plate 5 is extended and welded to the first connecting plate 2, and the two angle-adjusting steel plates 7 are extended to the other end and welded and fixed to the second connecting plate 3.

[0043] Two columnar lead cores 6 respectively traverse two elastic bodies 4 and three shear steel plates 5 and are distributed along the arc length direction of the composite elastic body 1; bolts 9 are equidistantly distributed on both sides of the columnar lead core 6 along the arc length direction, and the bolts 9 There are four groups in total, with eight on each side and sixteen in total. The center angle between the centers of adjacent bolts 9 on the same arc length is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com