Screw connection of hinge parts

A bolt and hinge technology, applied in the direction of bolts, connections, connecting components, etc., can solve problems such as high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now in conjunction with accompanying drawing, the present invention is described in detail as follows:

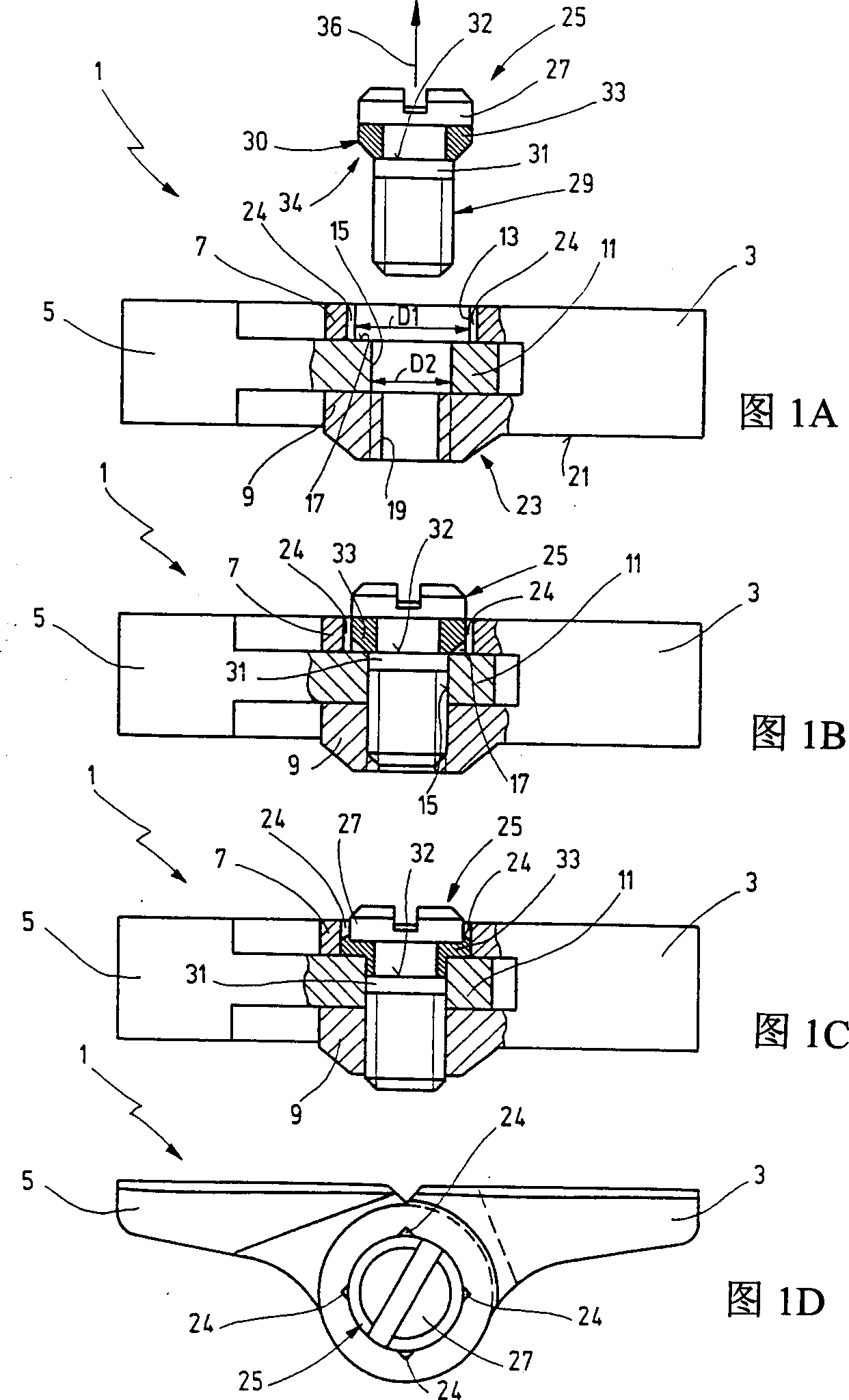

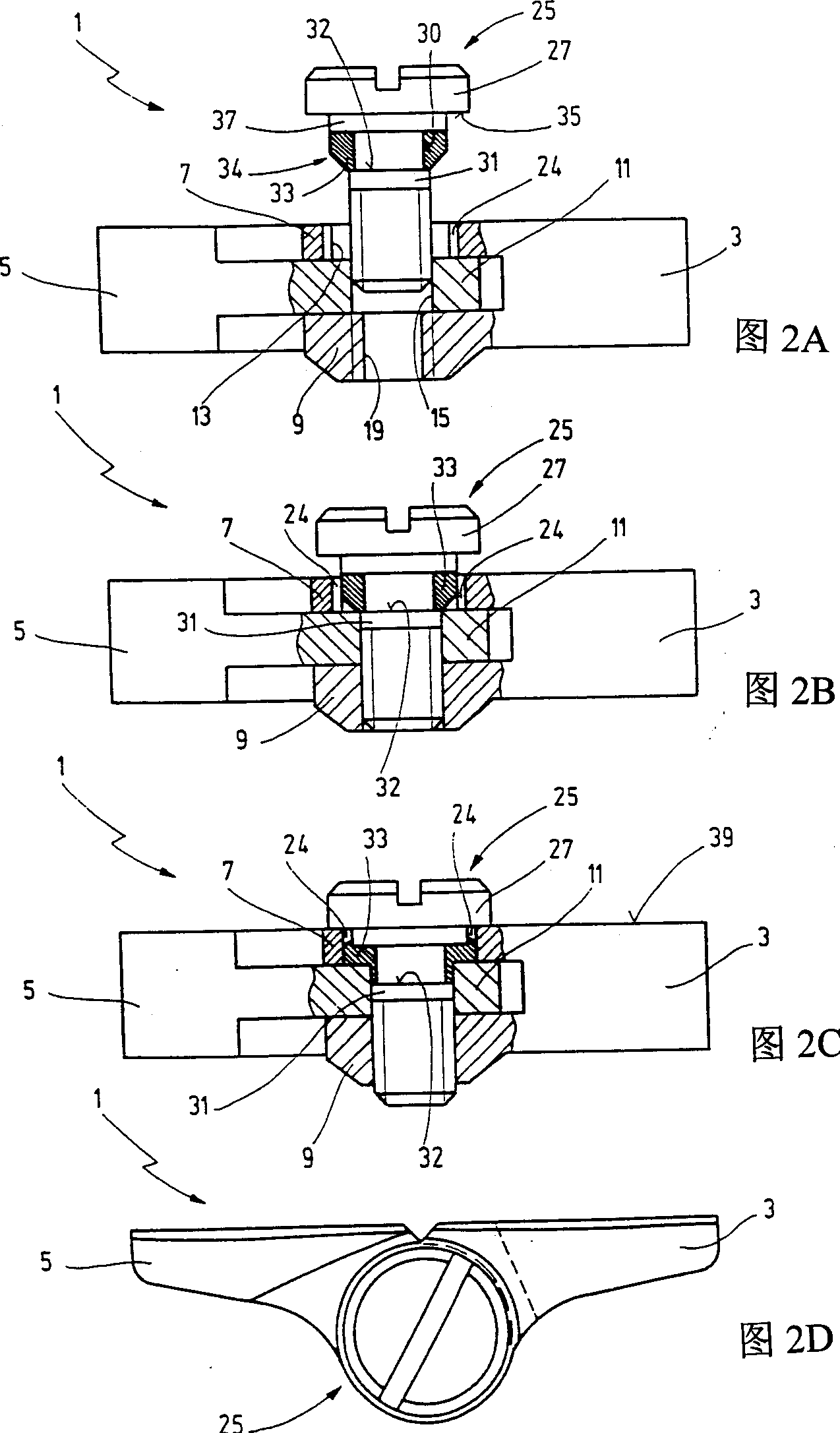

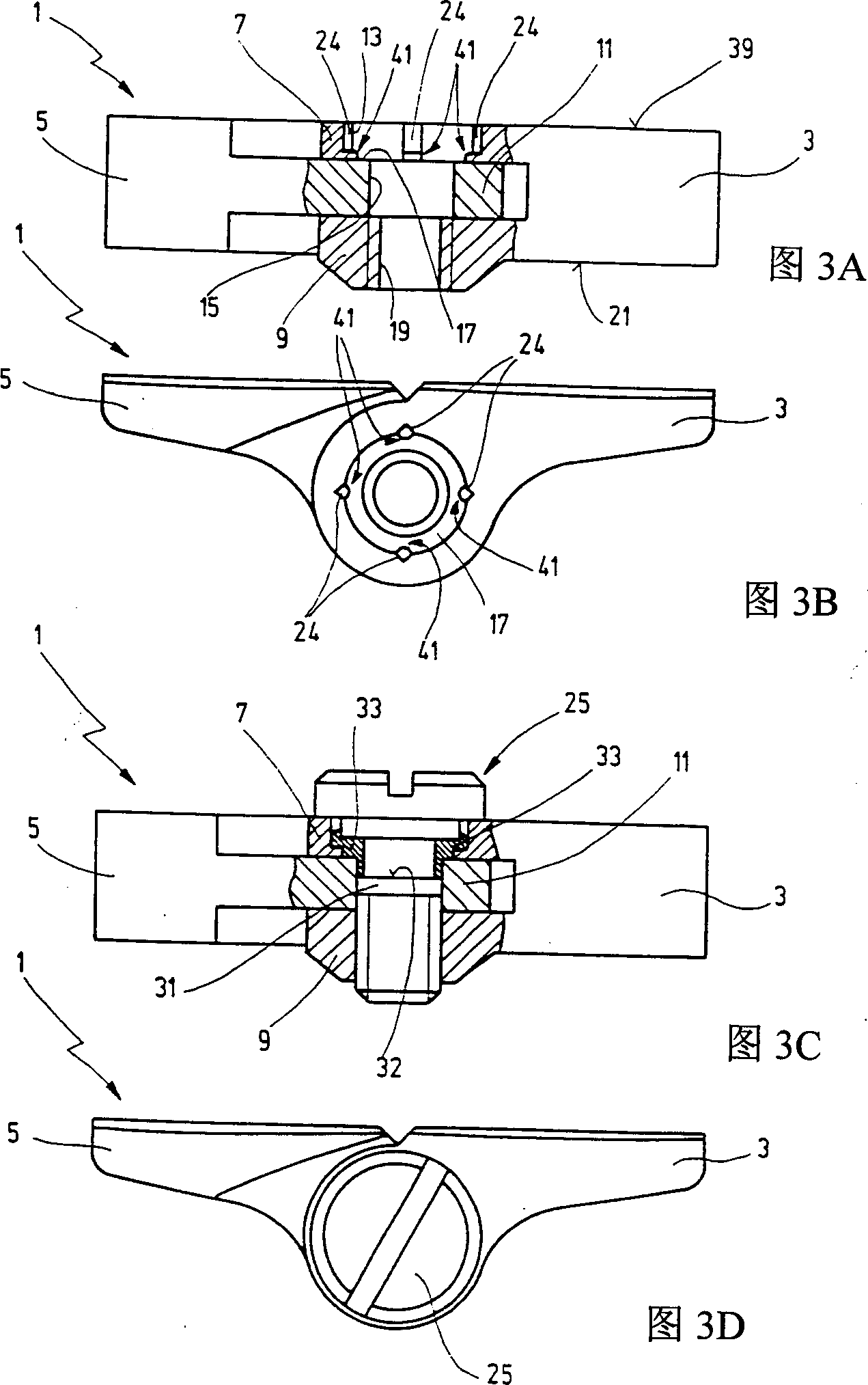

[0025]FIG. 1A shows a longitudinal section through a screw connection 1 of a hinge part, such as a spectacle frame, comprising a double-leaf hinge 3 and a single-leaf hinge 5 which are inserted into each other. Assume that the double-piece hinge 3 is connected with the spectacle frame, and the single-piece hinge 5 is connected with the spectacle leg. The double-leaf hinge 3 has an upper hinge lug 7 and a lower hinge lug 9, while the single-leaf hinge 5 has a middle hinge lug 11 between the upper and lower hinge lugs 7 and 9, the smaller the gap the better . A first through hole 13 emerges from the upper hinge lug 7 and a second through hole 15 emerges from the middle hinge lug 11 so that the longitudinal axes of said through holes are concentric. The through-holes 13 and 15 are designed here as circular cross-sections. In another embodiment, the cross section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com