ECC axial tension test deformation monitoring system and method

A technology for deformation monitoring and test pieces, which is applied in the direction of measuring devices, climate change adaptation, and the use of stable tension/pressure test material strength, etc., can solve the problems of only monitoring specified size test pieces, slippage of fixed brackets, fracture damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

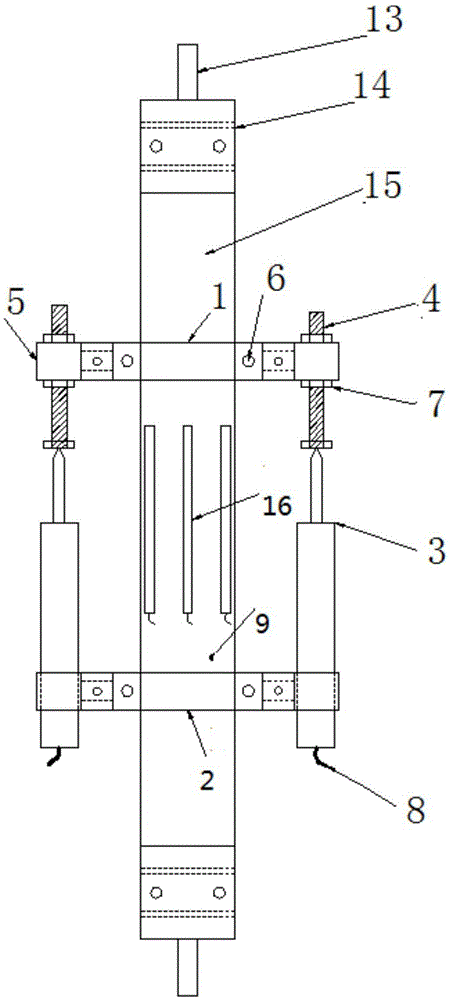

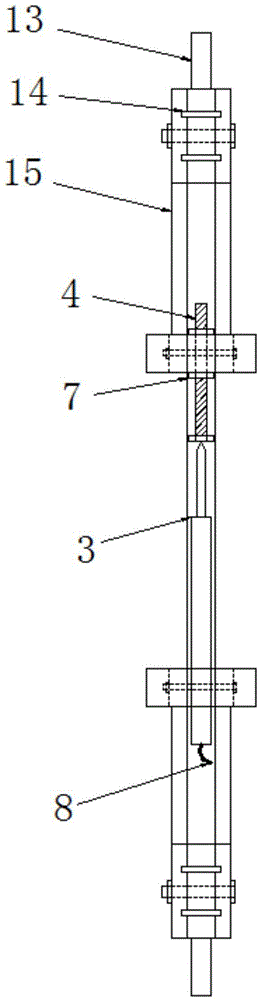

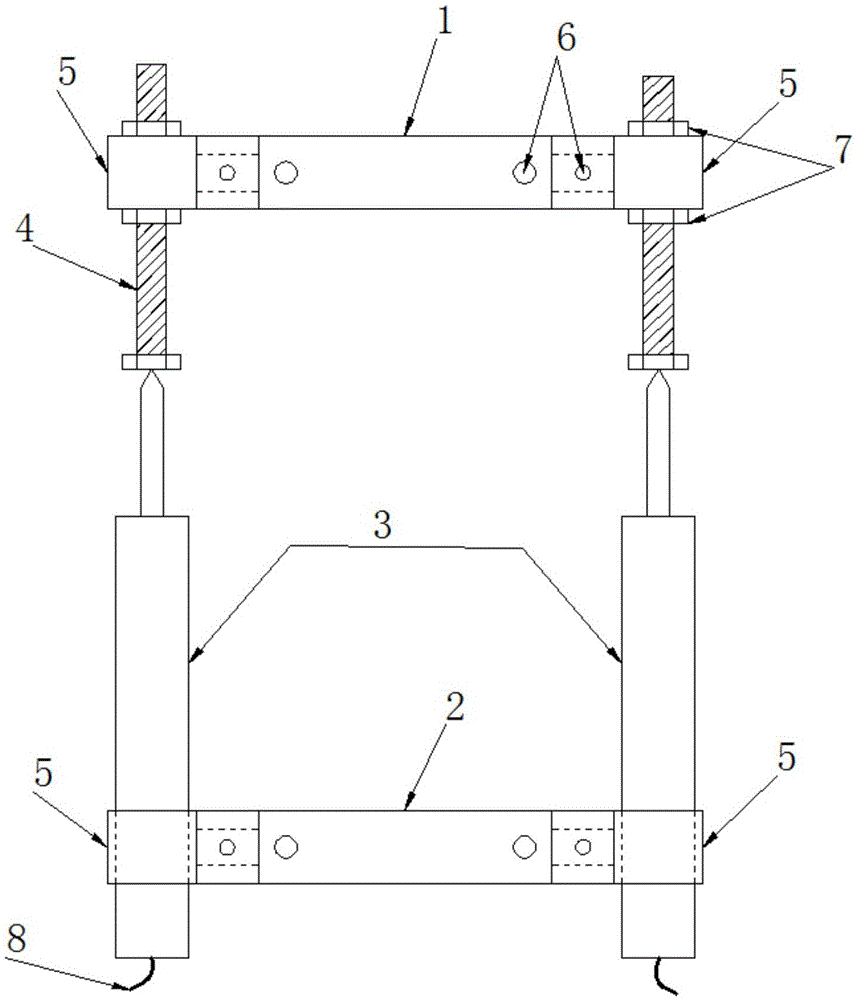

[0041] Below in conjunction with the accompanying drawings, the test method of the fixture and the displacement monitoring system for the direct tensile test of the ultra-high toughness cementitious composite (ECC) according to the present invention will be further described by implementing examples. The test equipment used in the direct tensile test is a computer-controlled electronic universal testing machine with a loading rate of 0.1mm / min.

[0042] Such as Figure 1(1) , 1(2) As shown, it is used for the tensile test fixture and displacement monitoring system of ultra-high toughness cementitious composite (ECC), mainly including two tensile fixtures, a set of templates for fixing the tensile fixture and a set of LVDT displacement Sensor fixing bracket, two rebound LVDT displacement sensors 3 and a collection box.

[0043] Wherein the stretching fixture comprises two clamping steel plates 15 and a stretching chuck 13 with a universal hinge. The steel plate and the chuck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com