Seam tracking device with double tracking probes

A tracking device and double-tracking technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as poor anti-interference ability, complex principle, difficult maintenance, etc., achieve high reliability, high tracking accuracy, and improve welding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with examples.

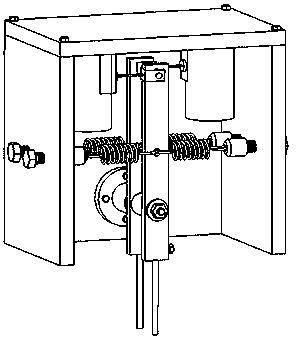

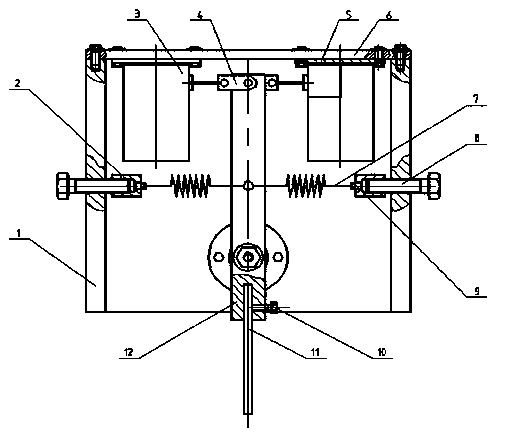

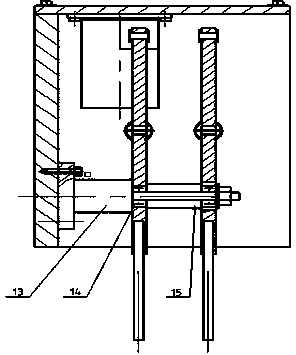

[0020] In the figure, 1-box body, 2-bolt connection block, 3-position motion sensor, 4-guide rod connection head, 5-sensor mounting flange, 6-upper box cover, 7-spring, 8-adjusting bolt, 9 -spring hook 10-probe fixing bolt, 11-tracking probe, 12-guide rod, 13-cantilever beam, 14-rolling bearing, 15-shaft sleeve.

[0021] The components of the double tracking probe weld seam tracking device are installed inside the box body, and a cantilever beam 13 is installed below the center line of the box body. A guide rod 12 is respectively installed in the middle and front of the cantilever beam. The position is fixed by the axle sleeve 15, and the guide rod can flexibly swing with the cantilever beam as the axis. In order to reduce the friction in the swing process, a rolling bearing 14 is arranged between the two swing bars and the cantilever beam. There is a through hole in the middle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com