Full-fabricated concrete beam-column connector based on energy dissipation pieces and shearing resistance pieces and beam-column connecting method

A technology for shear-resistant parts and connectors, which is applied to building components, protective buildings/shelters, earthquake-proof and other directions. Ductile, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

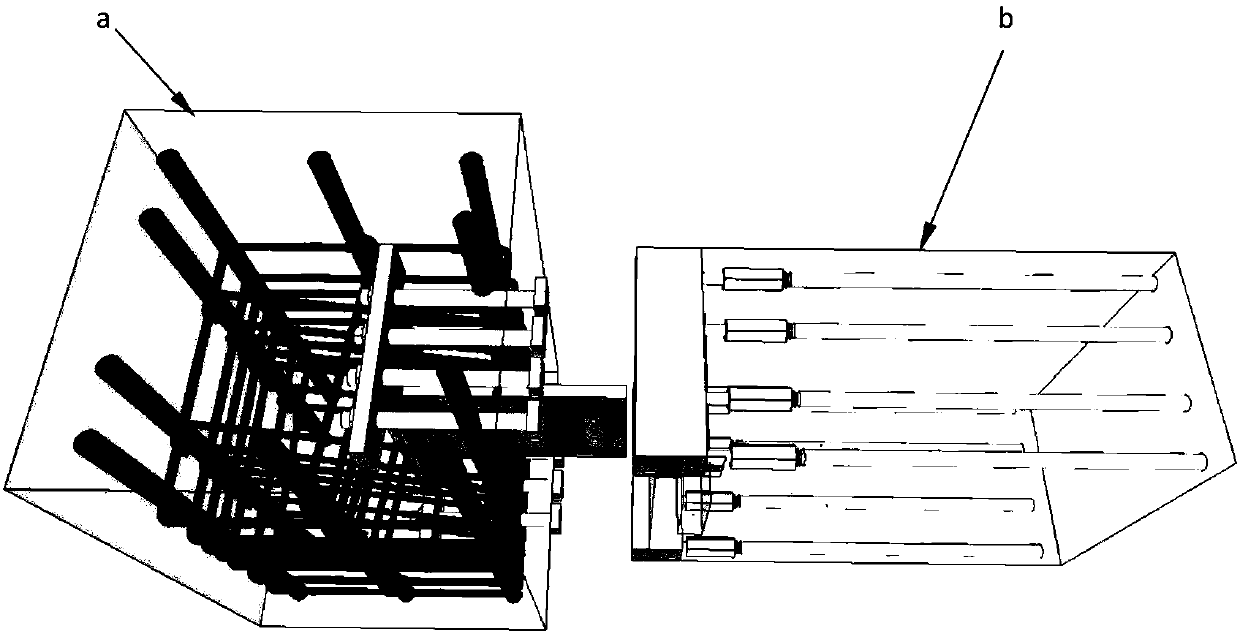

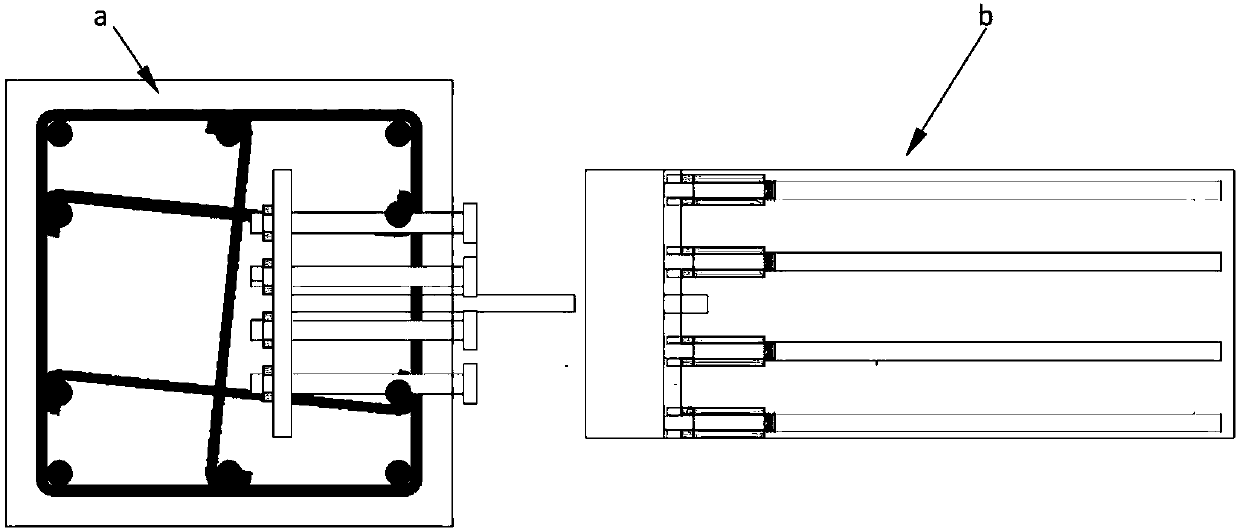

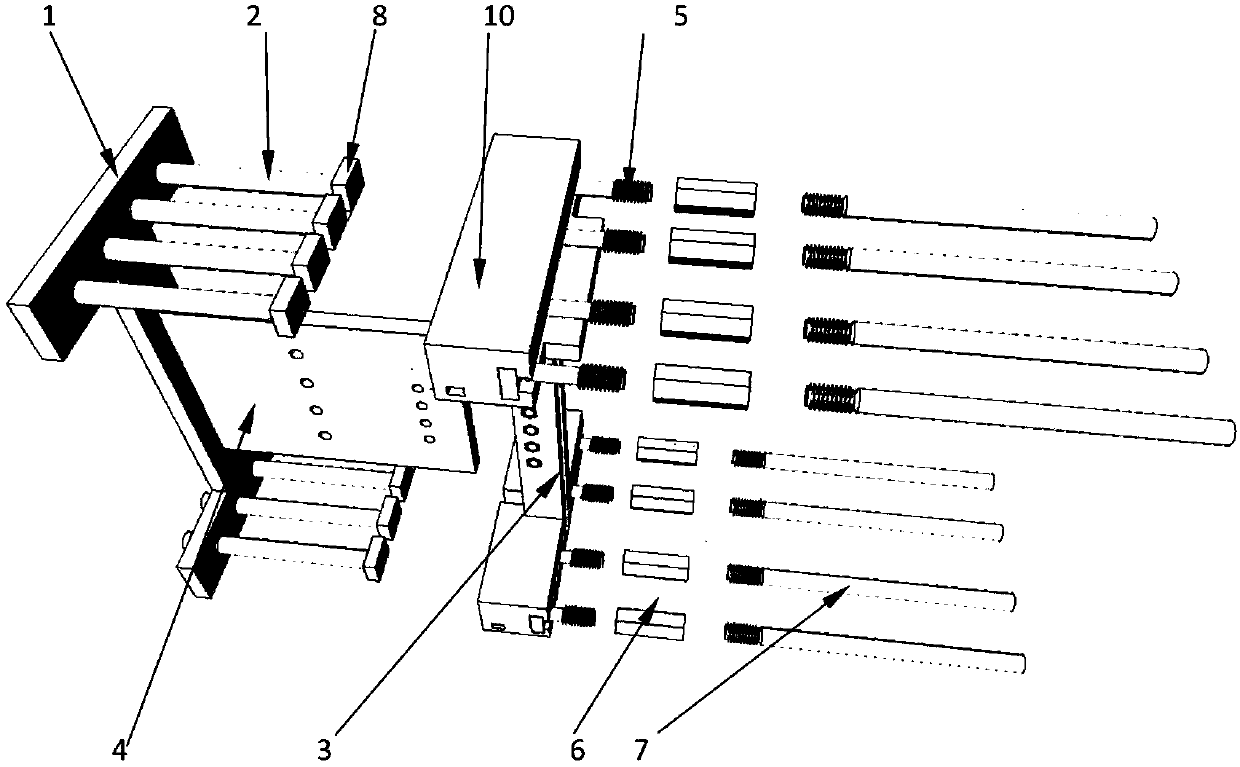

[0035] In order to express the object, technical solution and advantages of the present invention more clearly, the present invention will be further introduced below in conjunction with the accompanying drawings.

[0036] The invention proposes a beam-to-column connector, which includes three parts, one is the energy-dissipating parts and their anchors embedded in the concrete column, the other is the conversion block embedded in the beam end, and the third is the connecting beam Shear members of the column.

[0037] see details Figure 1-8 As shown, the connector includes energy dissipation parts (2) embedded in precast concrete frame columns, anchors (1), shear parts (4) and conversion blocks (10) embedded in precast concrete frame beam ends and The shear member connection column (3), the energy dissipation member (2) is fixedly connected with the anchor member (1), and the T-shaped connector (5) is installed on the side of the conversion block (10), and the T-shaped conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com