Method for analyzing dynamic characteristics of bolted structure based on three-dimensional fractal theory

A technology of fractal theory and analysis method, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as limitations, influence of statistical parameters, inability to consider multiple influencing parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

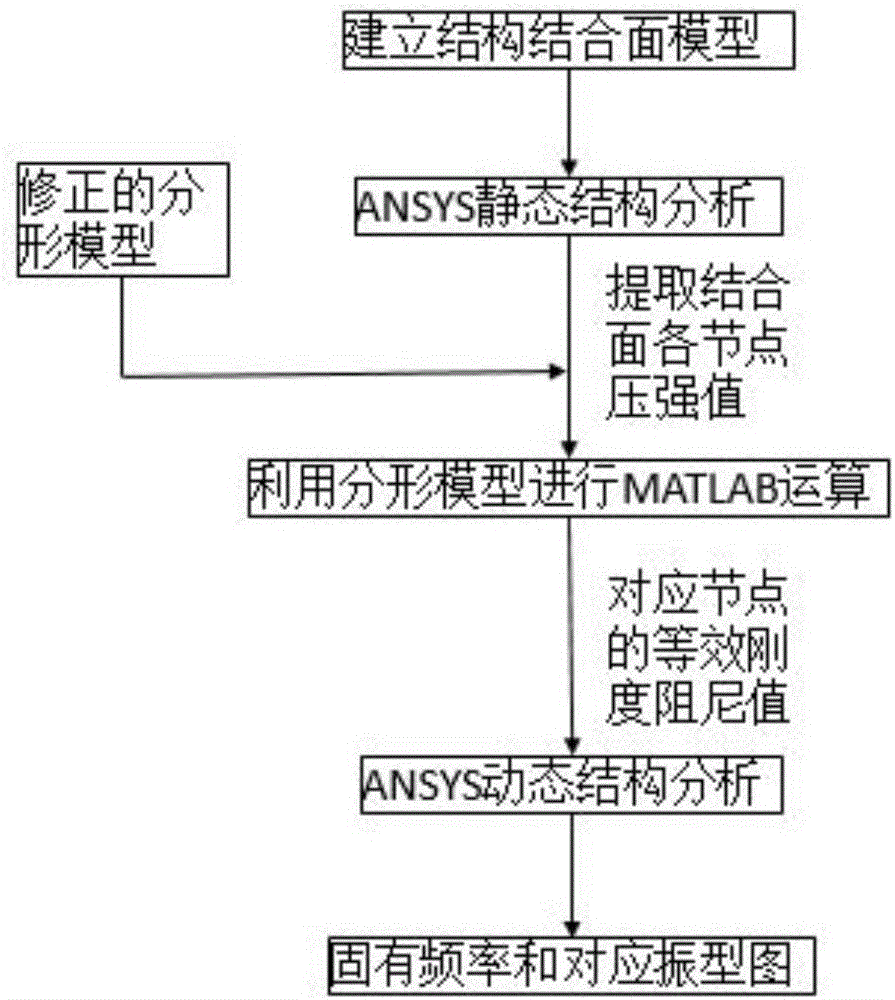

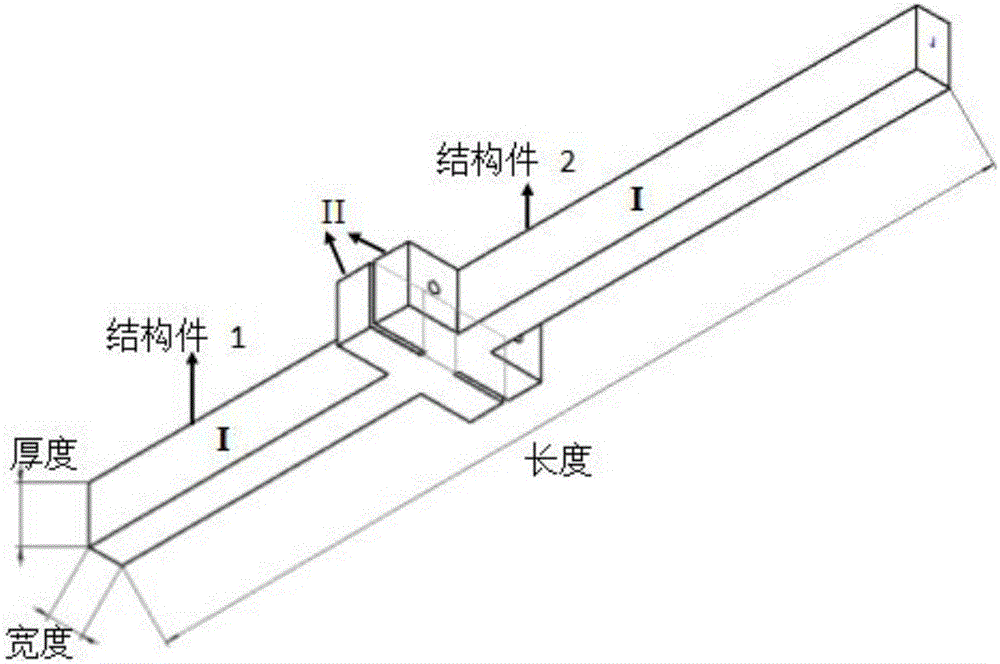

[0018] The following is attached Figure 2-5 The present invention will be described in further detail.

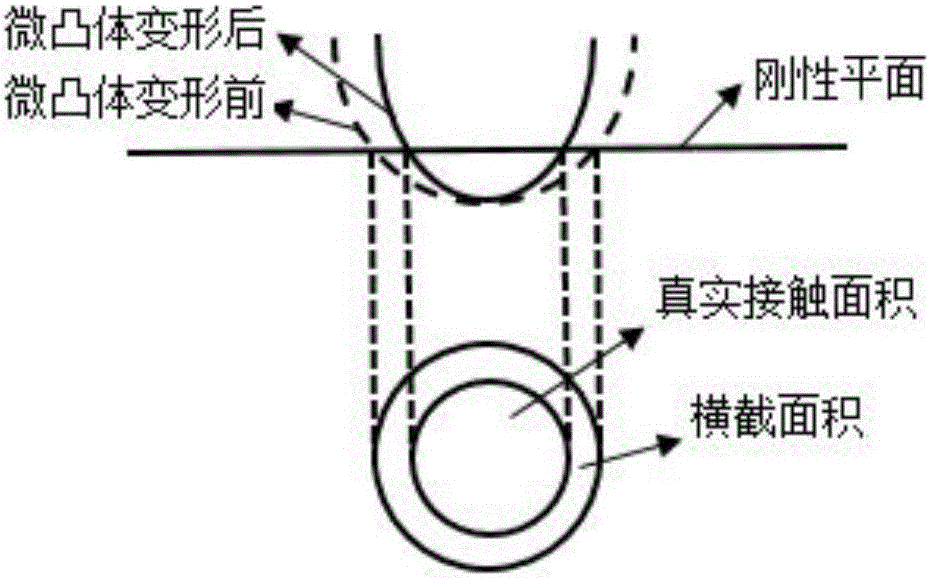

[0019] Step (1) Establish a three-dimensional joint surface stiffness and damping model

[0020] Based on the MB fractal theory, combined with the Hertz theory, and considering the elastoplastic deformation and the domain expansion factor ψ, the total elastic normal load, elastoplastic normal load and the normal load of a single asperity in different deformation regions can be integrated. The total plastic normal loads are as follows:

[0021]

[0022]

[0023]

[0024] Where H G1 ,H G2 Both are coefficients related to material properties and fractal parameters of the joint surface, H is the hardness of the softer material, H=2.8Y (Y is the yield strength value); k is the parameter related to Poisson's ratio, k=0.454+0.41ν; a' 1c ,a′ 2c They are the critical cross-sectional area between elastic, elastoplastic and plastic deformation.

[0025] Then the total normal load of the joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com