Dual-sliding shaft floatation supporting mechanism of omnibearing movable AGV (Automatic Guided Vehicle)

A floating support, mobile technology, applied in the field of mechanical structure, can solve problems such as movement obstruction, inability to correct, AGV deviation, etc., to achieve the effect of improving stability, reducing vibration, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

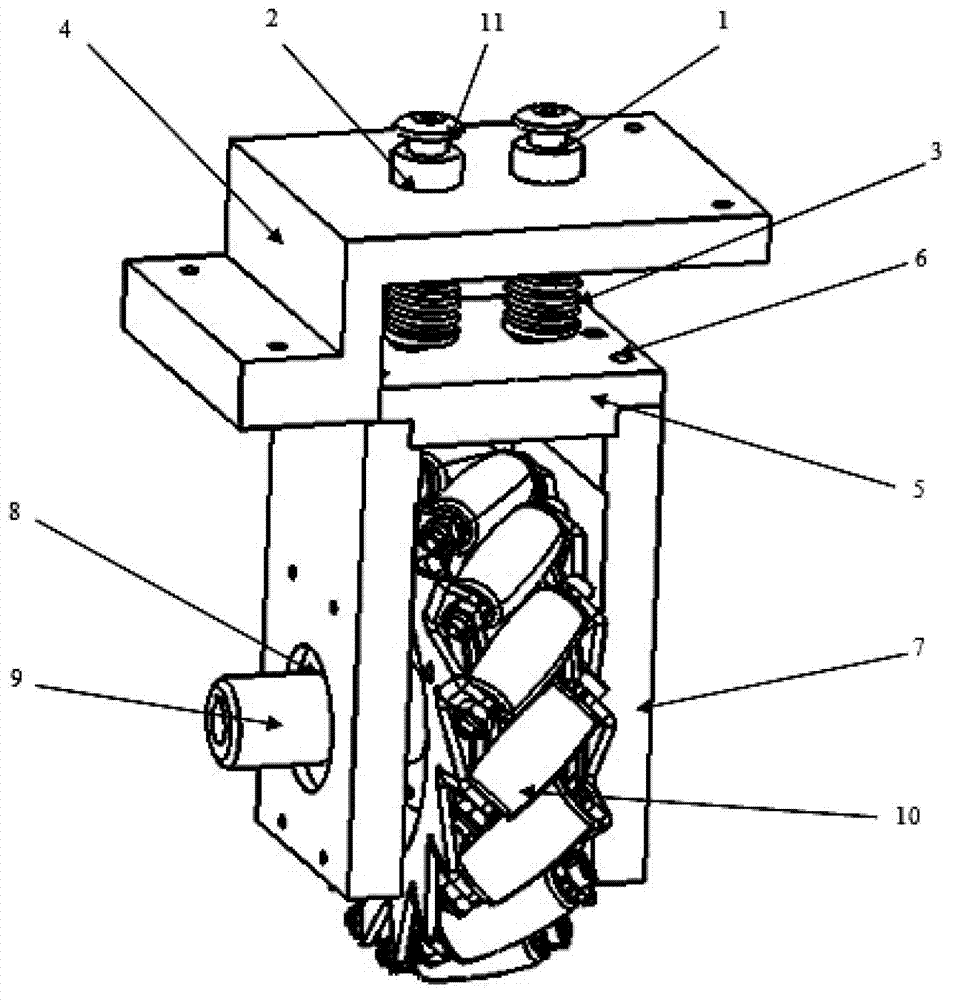

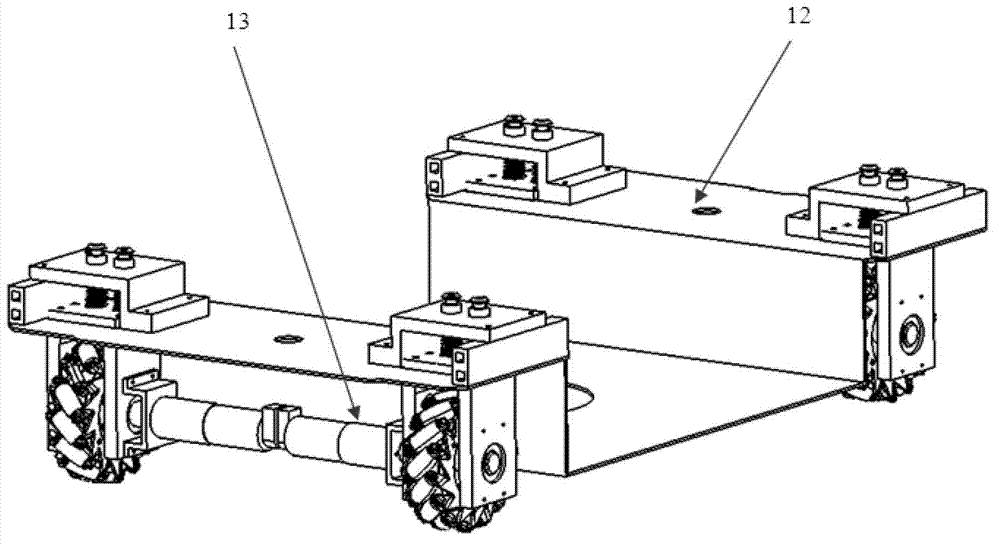

[0020] figure 1 It is a mechanism diagram of the present invention, such as figure 1 As shown, the double-sliding shaft floating support mechanism of the omni-directional mobile AGV provided by the present invention includes: two sliding shafts 1, two sliding linear bearings with flanges 2, two rectangular coil springs 3, and a fixed plate 4 , bracket 5, two positioning pins 6, two bearing housings 7, two radial ball bearings 8, motor shaft 9 and mecanum wheel 10, the mecanum wheel 10 is fixed on the motor shaft 9, two centripetal The ball bearings 8 are installed at both ends of the motor shaft 9 respectively, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com