Guide rail tension mechanism of cutting machine with water tank

A water tank cutting machine and tensioning mechanism technology, which is applied to stone processing tools, working accessories, manufacturing tools, etc., can solve the problems of large axial clearance in the vertical direction, large end face beating of cutting saw blades, and influence on wide use, etc., to achieve The effect of reducing labor intensity, improving processing accuracy and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

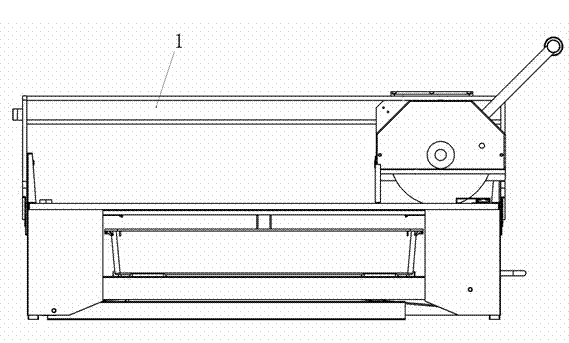

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

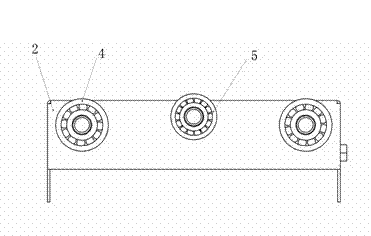

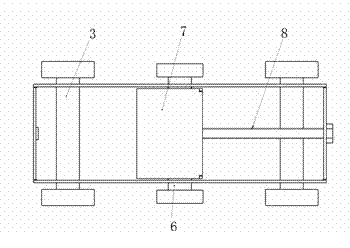

[0011] Such as figure 1 , 2 Shown in and 3: a water tank cutting machine guide rail tensioning mechanism, which is installed in the sliding long groove of the guide rail 1 of the cutting machine, including a guide rail connecting plate 2, a bearing support rod 3, a first bearing 4, and a second bearing 5 , the tensioning shaft 6, the tensioning plate 7 and the adjusting bolt 8, the two ends of the guide rail connecting plate 2 are provided with a bearing support rod 3, and the end face of the bearing supporting rod 3 is equipped with a first bearing 4, and on the guide rail connecting plate 2 A tensioning shaft 6 is provided, and the tensioning shaft 6 is connected with the tensioning plate 7 and the second bearing 5, and the tensioning plate 7 is connected with the adjusting bolt 8.

[0012] It should be pointed out that those skilled in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com