Automatic Tab Welding Device

A tab welding, fully automatic technology, applied in the direction of welding equipment, electrode characteristics, resistance welding equipment, etc., can solve the problems of low production efficiency, poor welding quality of negative tabs, etc., to improve welding quality, uniform and stable force, The effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

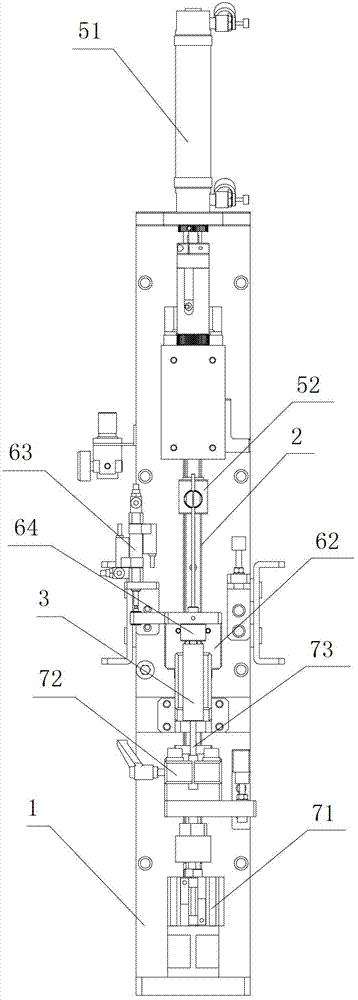

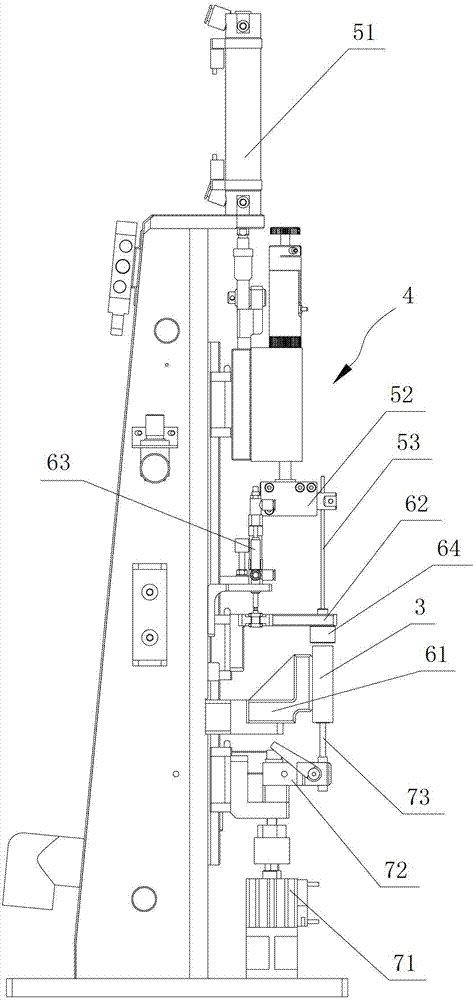

[0033] Such as figure 1 with figure 2 Commonly shown is a schematic structural diagram of a fully automatic tab welding device of the present invention, which is only a part of the battery processing equipment and should be used in conjunction with other components in actual use. Other components are not shown here, only This device will be described.

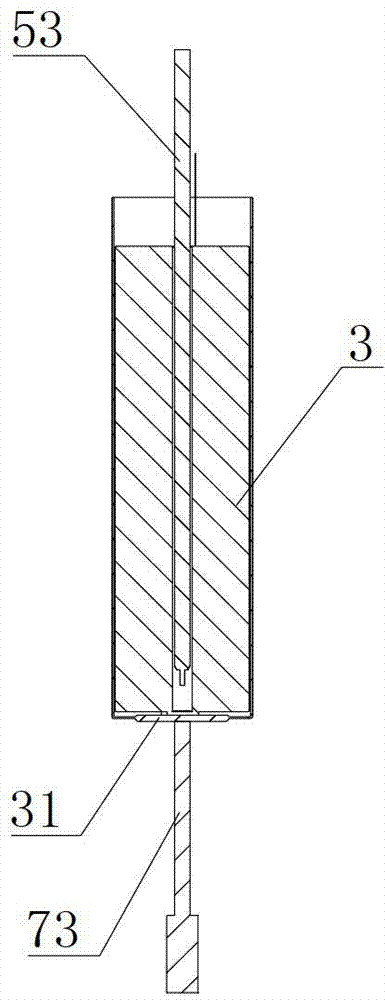

[0034] The fully automatic lug welding device firstly includes a machine base 1, on which a guide rail 2 is vertically arranged, on which a positioning mechanism for positioning the electric core 3 is provided, specifically:

[0035] The positioning mechanism includes a cell positioning block 61 fixed on the guide rail 2. By placing the cell 3 on the cell positioning block 61, it can be fixed in its radial direction, and at the same time, the cell 3 can be moved up and down in its axial direction. move. There is also a welding needle guide plate 62 slidably arranged on the guide rail 2 above the electric core 3, which is dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com