Connecting structure for highway bridge comb plate expansion devices

A technology of telescopic devices and connecting structures, which is applied in bridges, bridge parts, bridge construction, etc., can solve problems such as adding telescopic devices, accidents, and affecting driving safety, so as to increase strength and integrity, improve service life, and ensure driving safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

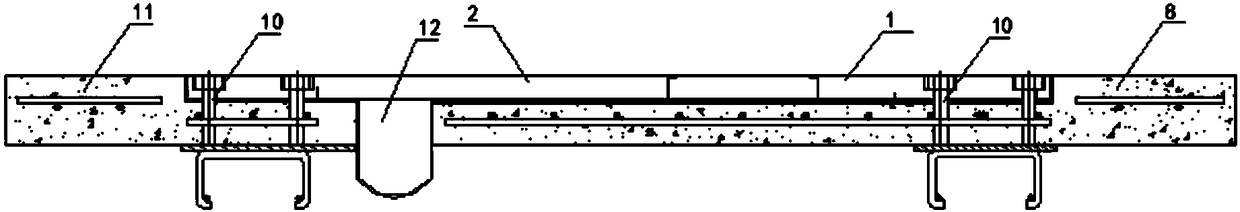

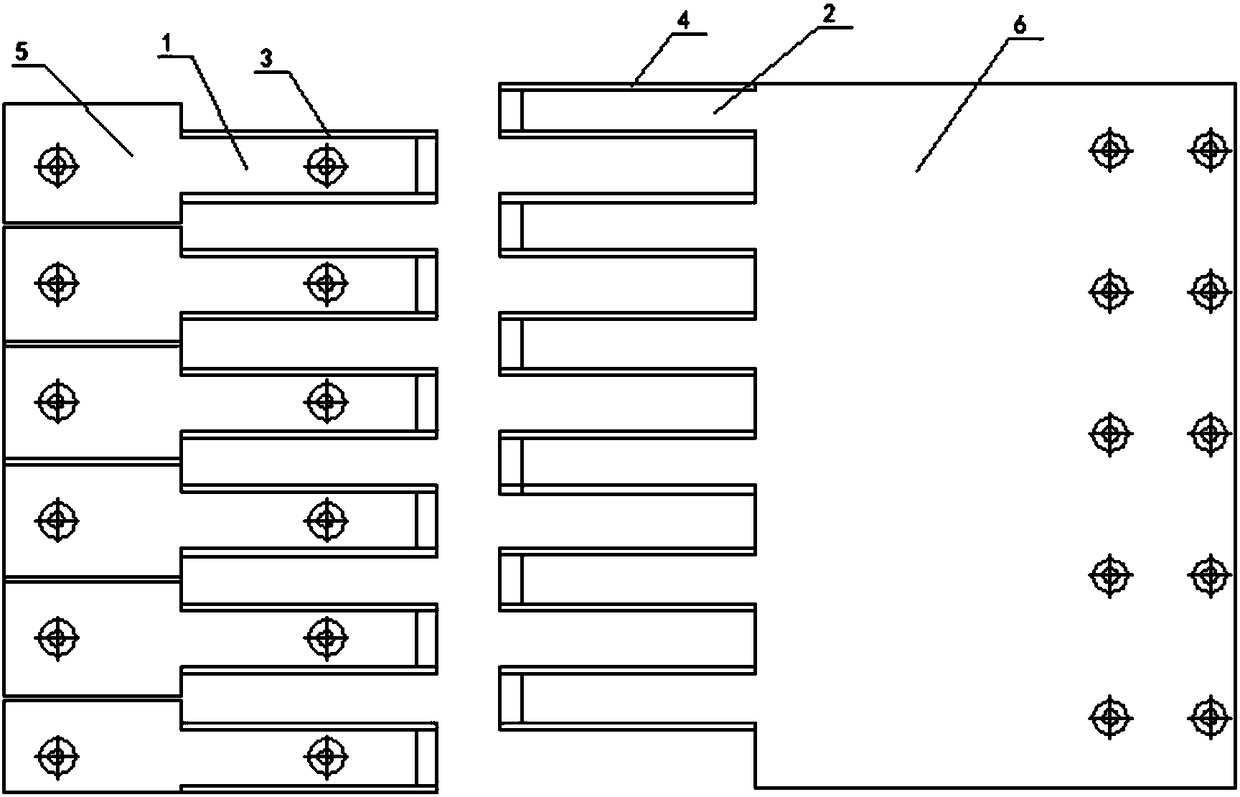

[0025] Example 1: See Figure 1-6 , a connection structure of a highway bridge comb plate telescopic device, comprising a fixed comb 1 connected to a fixed comb 5 and a plurality of gap-crossing combs 2 connected to a gap-crossing comb 6, wherein each fixed comb A set of fixed comb teeth 1 is arranged on the tooth plate 5, and six groups of comb teeth 2 are arranged on each comb tooth plate 6; The vertical sides adjacent to the fixed comb teeth 1 and the gap-spanning comb teeth 2 are all provided with inlaid and occluded mortise and tenon structures. The protruding block 4 at the lower end of the side surface, the groove 3 is matched with the protruding block 4 . Wherein the fixed comb plate 5 and the gap-spanning comb plate 6 are all anchored in the embedded parts with anchor bolts, and the embedded parts are pre-embedded in the concrete layer 11 .

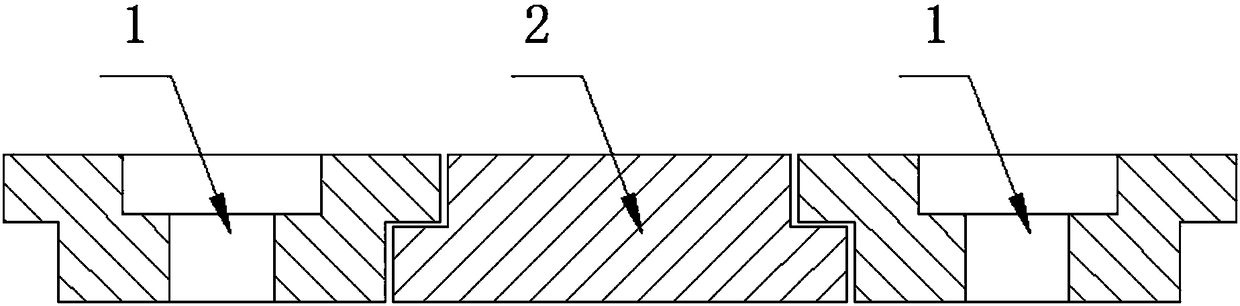

[0026] In the present invention, the adjacent vertical sides of the fixed comb teeth 1 and the slot-spanning comb teeth 2 are...

Embodiment 2

[0028] Embodiment 2: Same as Embodiment 1, except that each fixed comb plate 5 is provided with six groups of fixed combs 1 . The integral fixed comb tooth plate 5 is adopted to ensure that each fixed comb tooth 1 is on the same reference plane during installation, thereby improving installation efficiency.

Embodiment 3

[0029] Embodiment 3: Same as Embodiment 1, the difference is that both the fixed comb plate 5 and the fixed comb 1 are provided with an obliquely arranged ash shoveling surface 7 on the side facing the gap-spanning comb plate 6 . When the present invention is in use, the gap-spanning comb 2 slides freely in the horizontal direction. An open slot that is easy to accommodate dust is formed between the tooth plates 6. After a long time of use, the dust will block the open slot, causing the gap-spanning comb teeth 2 to continue to slide freely in the horizontal direction, making it lose the stretching effect. Therefore, the present invention can automatically shovel dust through the setting of the ash shoveling surface 7 when the comb teeth 2 slide across the gaps, and is especially suitable for areas with sandy dust environments, which greatly prolongs the service life of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com