Inflatable punching method and punching equipment for micro-spraying belt

A technology of punching equipment and micro-spraying tape, applied in metal processing and other directions, can solve the problems of cumbersome, inconvenient to use, inconvenient to control, etc., and achieve the effect of ensuring pressure balance, fast and efficient punching, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

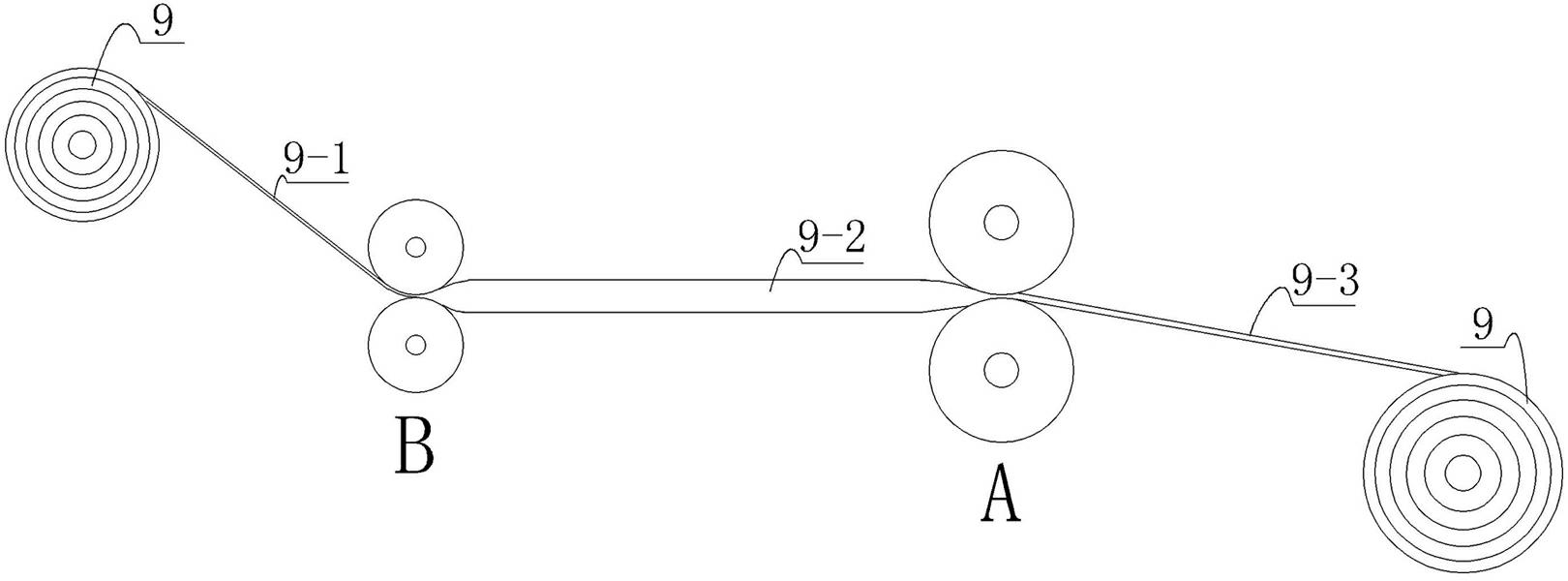

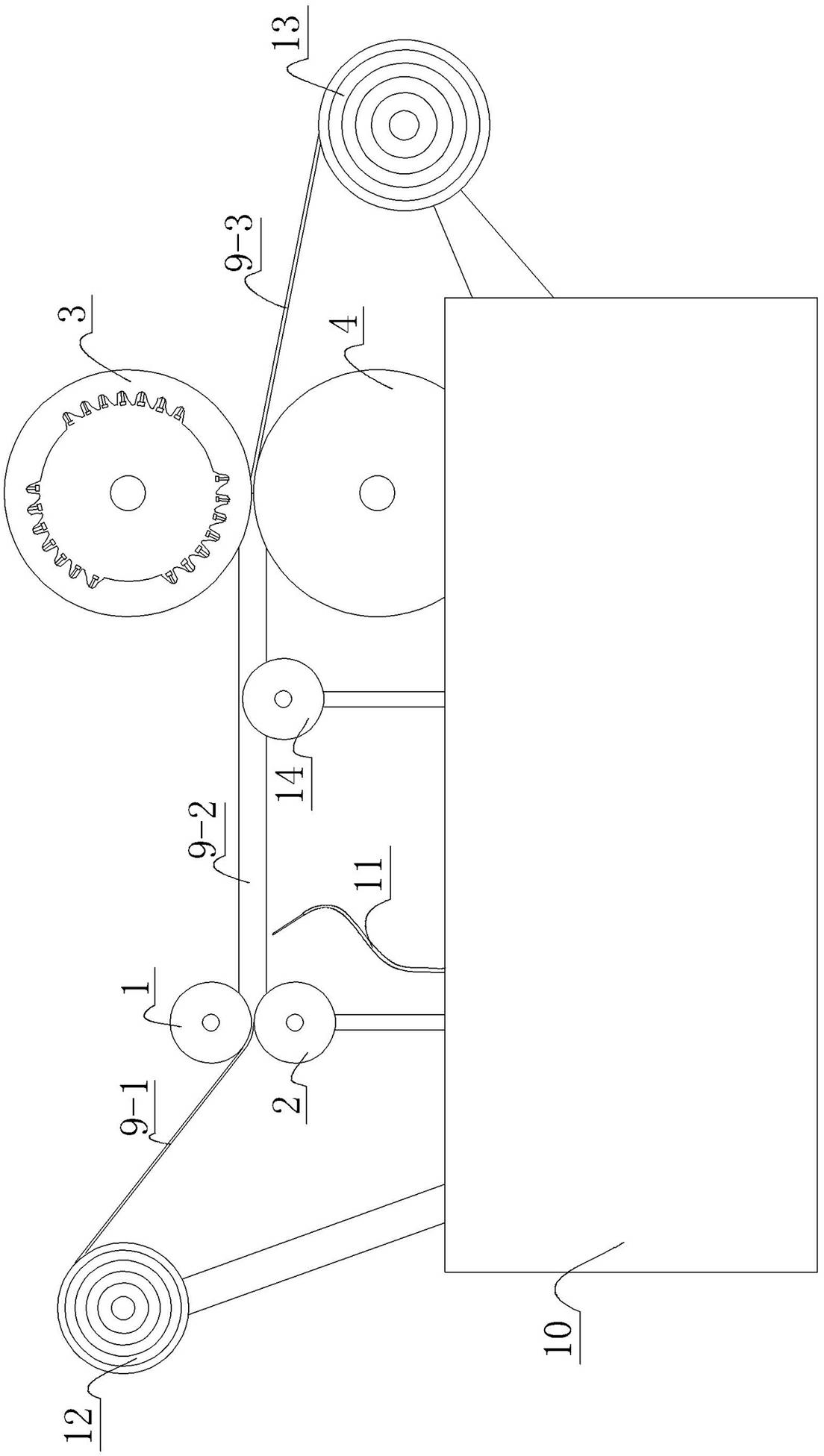

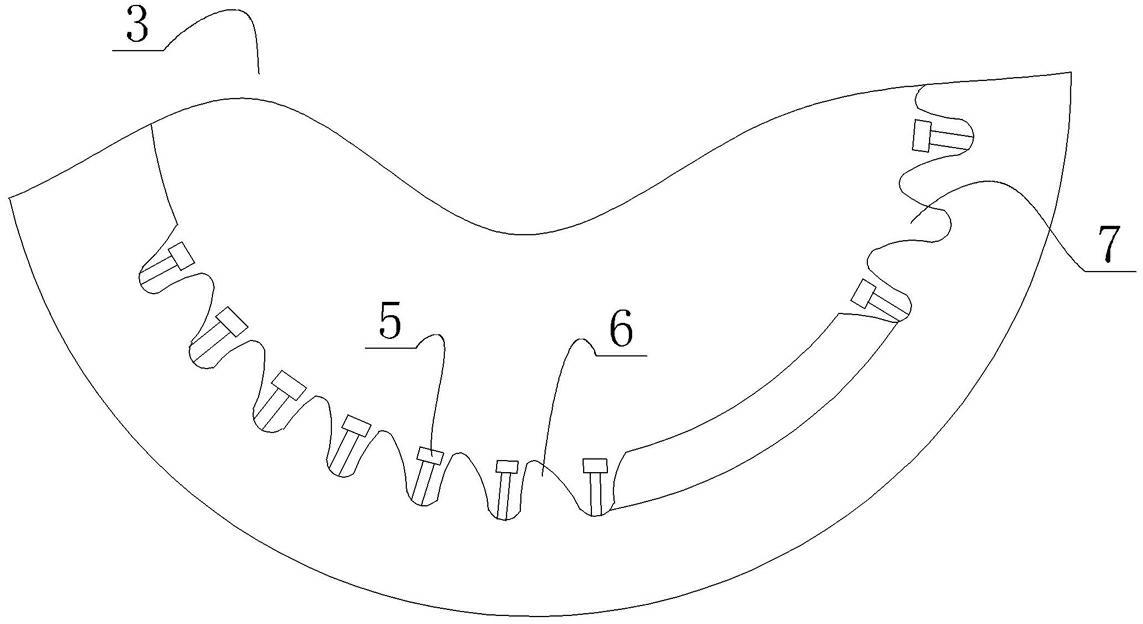

[0024] Combine below figure 1 The micro-spray belt inflatable punching method of the present invention is described, figure 1 Provided the principle diagram of the micro-spray belt inflatable punching method of the present invention, it comprises the following steps: a. extrude and seal, choose an end of the micro-spray belt to be perforated, adjacent to A and B at this end Carry out sealing with extruding device, so that the micro-spray belts on both sides of A place and B place both sides are not connected before perforating; And set A place at the front end of B place; Cooperating rolling wheels to squeeze and seal micro-spray strips. b. Inflate, fill gas into the micro-spray zone between A and B so that the upper wall and lower wall of the AB section of the micro-spray zone are not in contact; Spray belt (9-1), inflatable section micro spray belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com