Thin plate punching device for automobile part machining

A technology for auto parts and punching devices, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc. It can solve the problems of inability to perform automatic operations, poor connection of thin plates, misalignment of thin plates, etc., to achieve convenient laser drilling, Improve cohesiveness and fast punching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

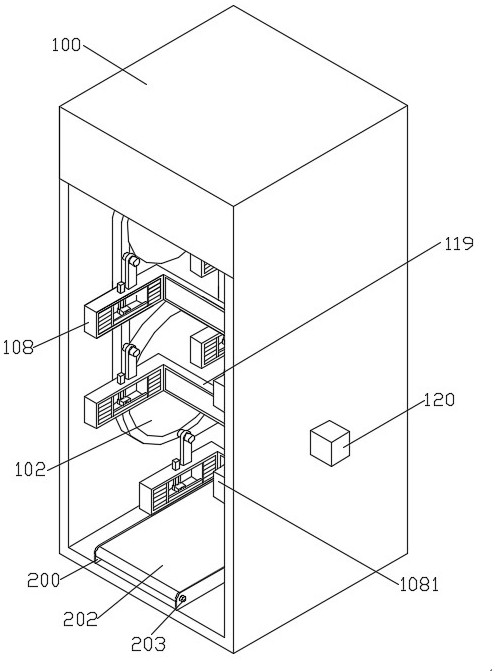

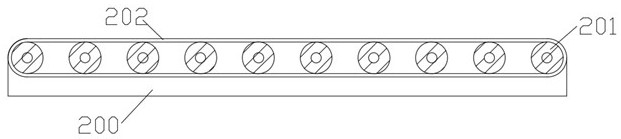

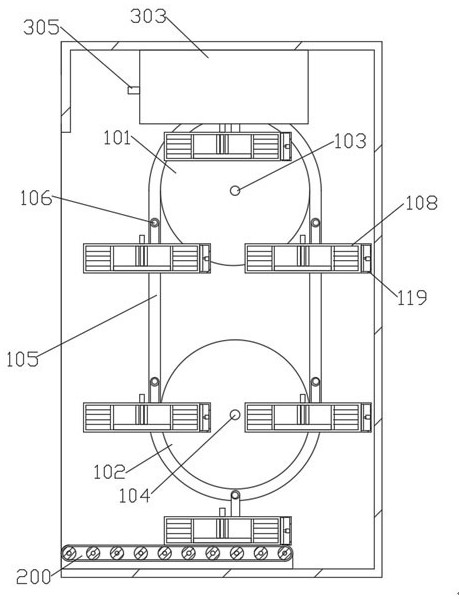

[0031] refer to Figure 1 to Figure 2 , a thin plate punching device for auto parts processing, comprising a punching frame 100, a fixing frame 200 is fixedly installed at the bottom of the punching frame 100, and a feeding and taking belt 202 is rotatably installed on the fixing frame 200. The fixing frame 200 is rotatably mounted with a plurality of delivery wheels 201 , and the plurality of delivery wheels 201 are connected by transmission through a delivery belt 202 . The fixed frame 200 is fixedly mounted with a delivery assembly 203 . The delivery assembly 203 may be a motor or a rotary cylinder, and the delivery assembly 203 is used to drive the delivery wheel 201 to rotate. The sheet is placed on the delivery belt 202, the delivery assembly 203 drives the delivery wheel 201 to rotate, the delivery wheel 201 drives the delivery belt 202 to rotate, and the delivery belt 202 transports the sheet. The stacked sheets are placed on the take-up belt 202, which conveys the st...

Embodiment 2

[0035] refer to Figure 8 On the basis of Embodiment 1, a blocking component 1191 is fixedly installed in the joint shell 119. The blocking component 1191 can be an air cylinder or an oil cylinder. The blocking component 1191 is used to drive the baffle 1192 to move. When the infrared sensor detects that the stacked sheets are not aligned front and rear, the positioning bar 112 at the corresponding position cancels the positioning of the sheets, and the rear blocking assembly 1191 pushes the baffle 1192, and the baffle 1192 pushes the misaligned sheets to align with the rest of the sheets, and the infrared The sensor sends a signal to the controller, and the positioning bar 112 continues to position the sheet. The blocking assembly 1191 and the baffle plate 1192 are provided to solve the problem of the front and rear misalignment of the stacked veneers when facing the stacked veneers conveyed on the belt 202 .

[0036] refer to Figure 6 to Figure 7 , an adjusting frame 303 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com