Method of manufacturing segment for flat commutator

A technology of a commutator piece and a manufacturing method, which is applied in the manufacture of commutators, the manufacture of stator/rotor bodies, electromechanical devices, etc., can solve the problems of unfavorable manufacturing costs, poor material utilization, and low surface hardness, and achieve cheap processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

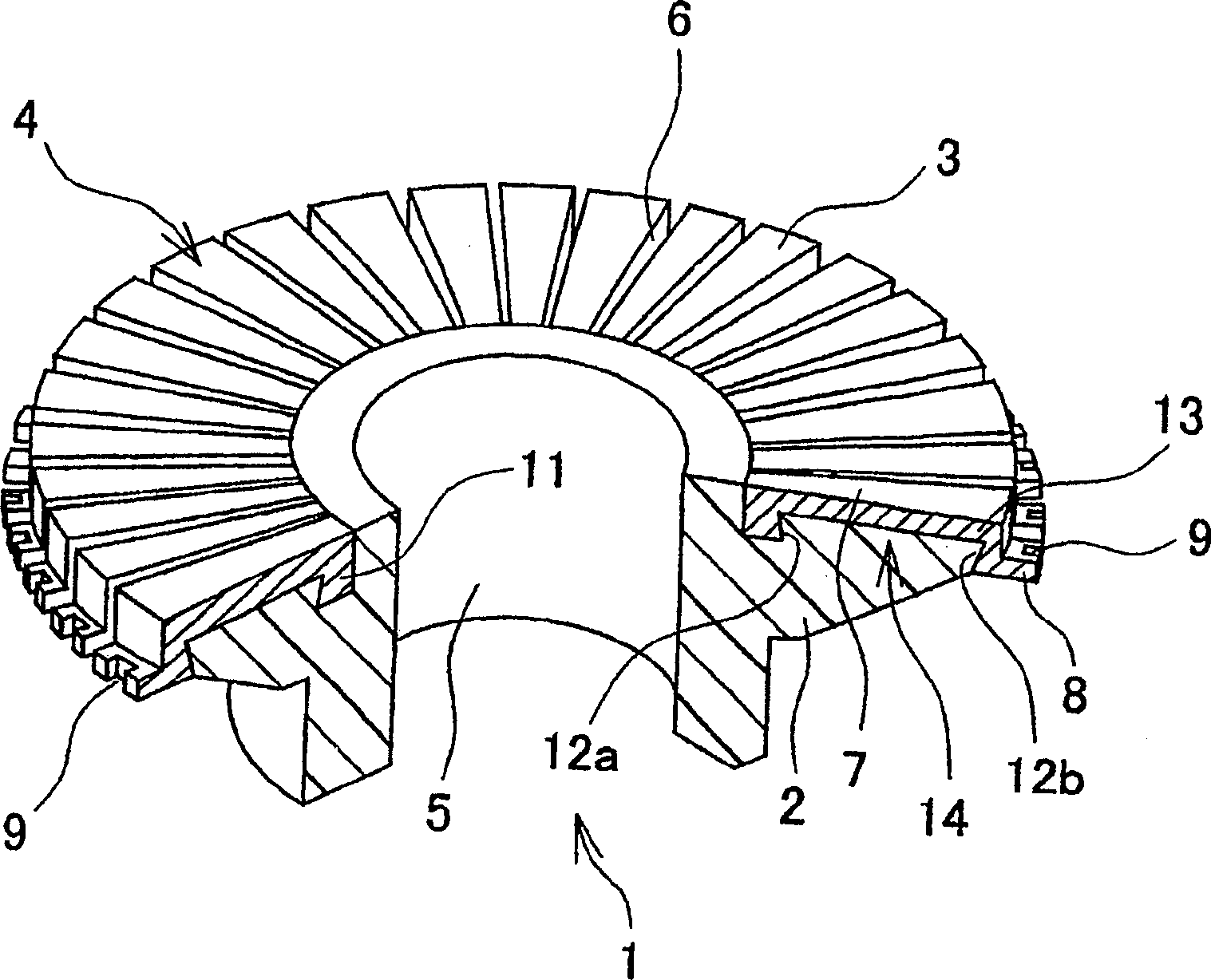

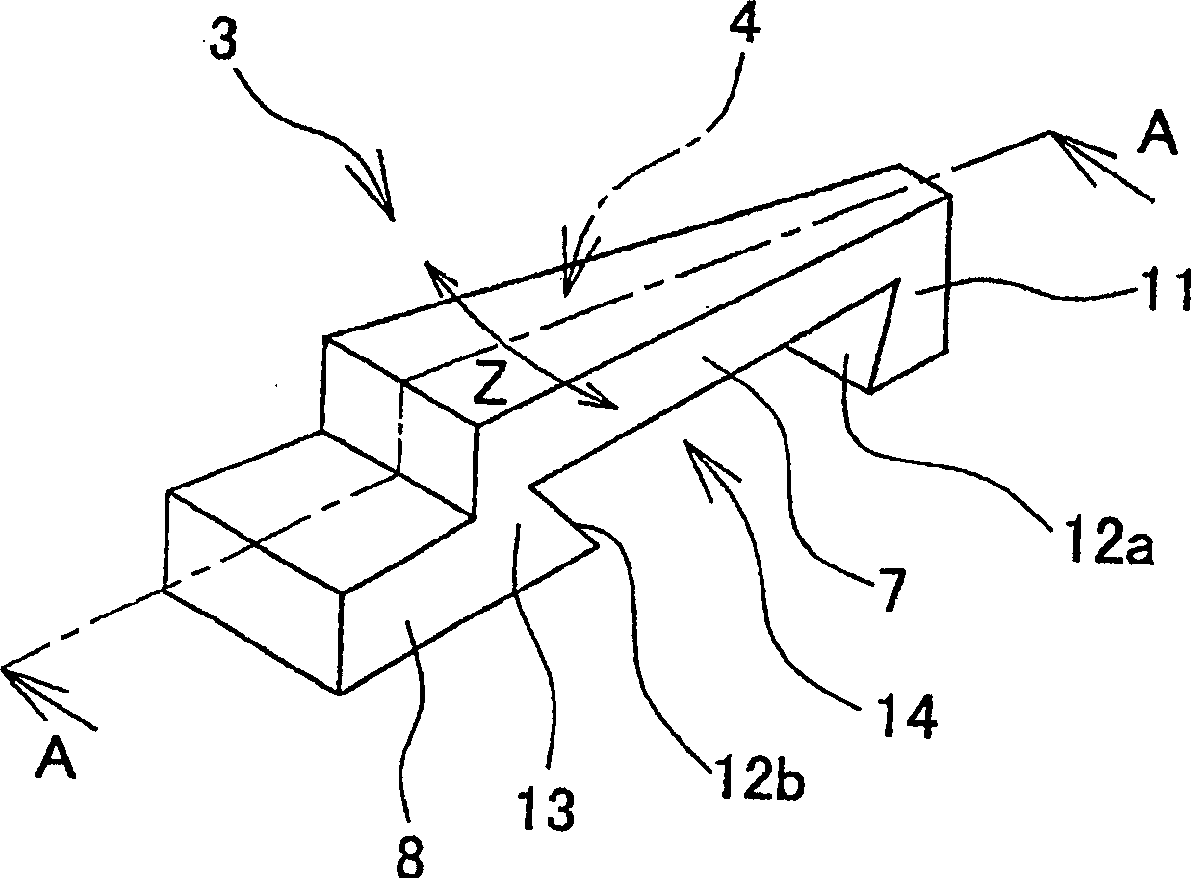

[0026] Embodiments of the present invention will be described in detail below based on the drawings. figure 1 It is a partially cutaway perspective view showing an example of a flat commutator using commutator segments manufactured by the manufacturing method of the present invention.

[0027] Such as figure 1 As shown, the commutator 1 constitutes a flat structure and is used in starter motors, fuel supply pumps in fuel tanks, and the like. The commutator 1 has a support part 2 made of synthetic resin and a plurality of metal commutator segments 3; the commutator segments 3 and the support part 2 are integrally molded. The surface of the commutator sheet 3 ( figure 1 The upper surface) becomes the brush sliding surface 4, which is in contact with the brush not shown in the figure from the axial direction.

[0028] In such a commutator 1, each commutator segment 3 is mounted on a circular frame, and the whole is molded with synthetic resin in this state. A rotating shaf...

Embodiment approach 2

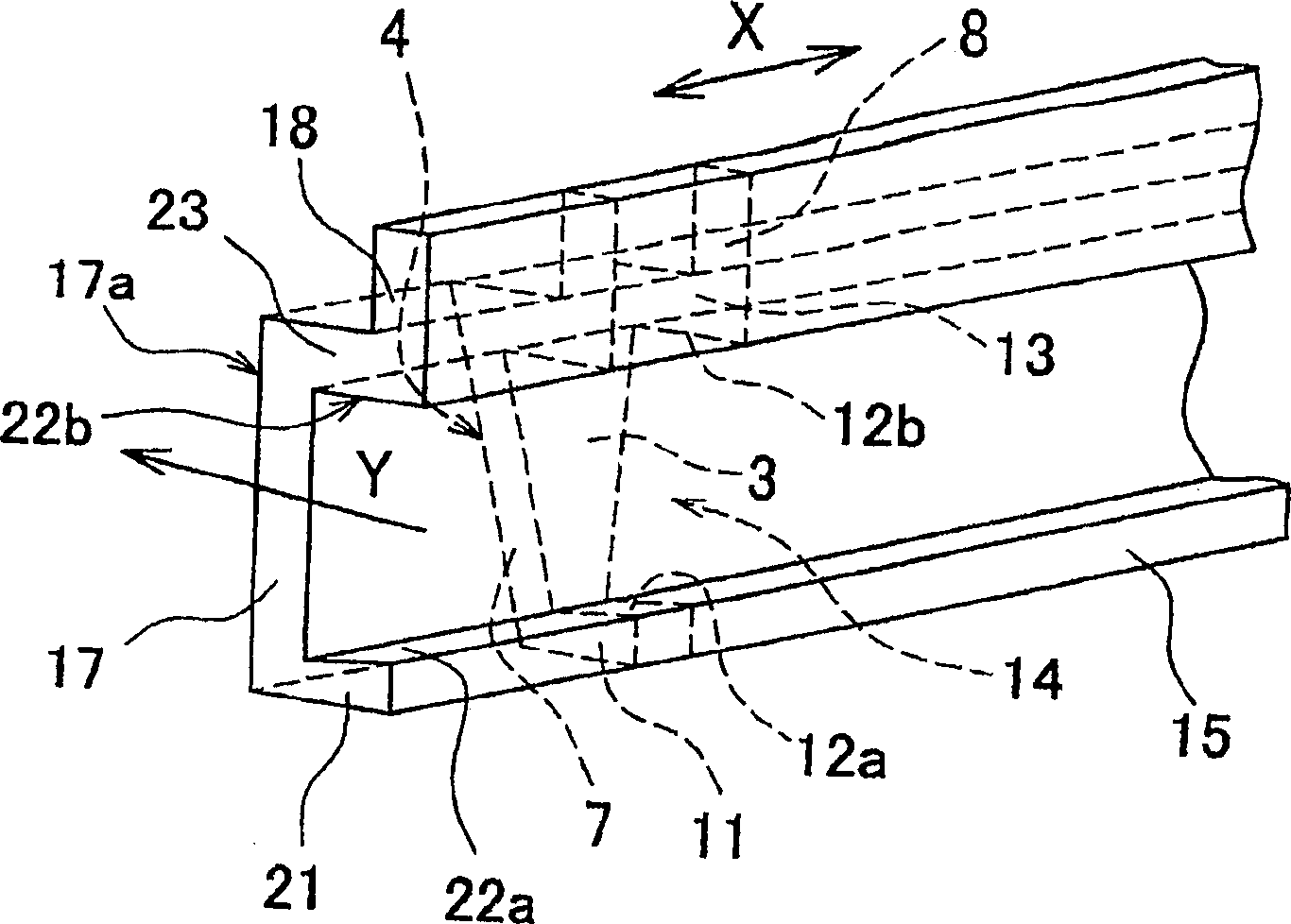

[0039] Figure 5 It is an explanatory diagram showing a method of manufacturing a commutator segment according to Embodiment 2 of the present invention. In addition, the same parts and components as those in Embodiment 1 are given the same reference numerals, and description thereof will be omitted.

[0040] In the manufacturing method of Embodiment 2, in order to further improve the material utilization rate of the commutator sheet 3, as Figure 5 As shown, the commutator profile (base metal) 25 is subjected to so-called cross-cutting. The commutator profile 25 punches adjacent commutator segments 3 in vertically opposite directions to form a portion having the same cross-sectional shape as that of the commutator segments 3 , forming a vertically symmetrical shape. That is, the outer peripheral forming portion 18 of the commutator profile 15 having the same cross-sectional shape as that of the commutator segment 3 is provided at both ends of the commutator profile 25 to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com