Full-automatic online punching bending plate system

A fully automatic, plate-bending technology, applied in printing plates, plate preparation, printing, etc., can solve the problems of general work efficiency, low work efficiency, and general precision of punching and bending plates, and achieve flexible operation interface, high-speed and efficient printing hole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

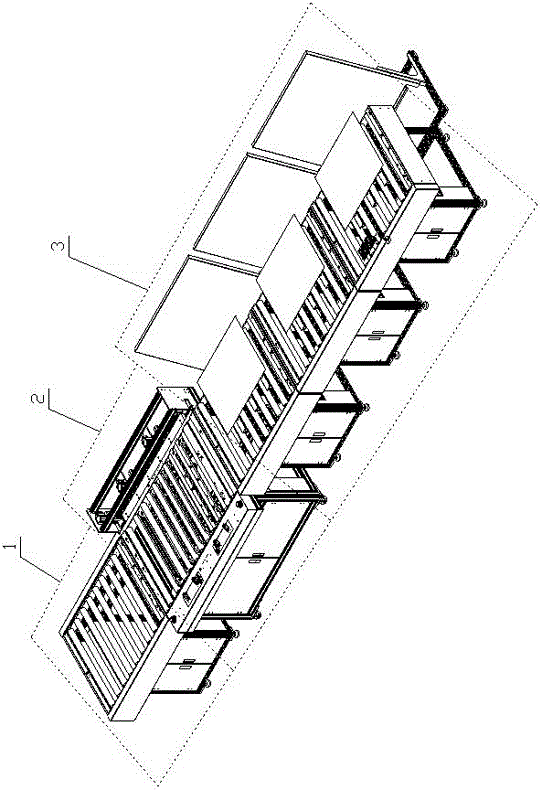

[0019] Such as figure 1 It shows an embodiment of a fully automatic online punching and bending system of the present invention, including a plate entry correction mechanism 1 , a bending and punching mechanism 2 , and a plurality of plate receiving mechanisms 3 .

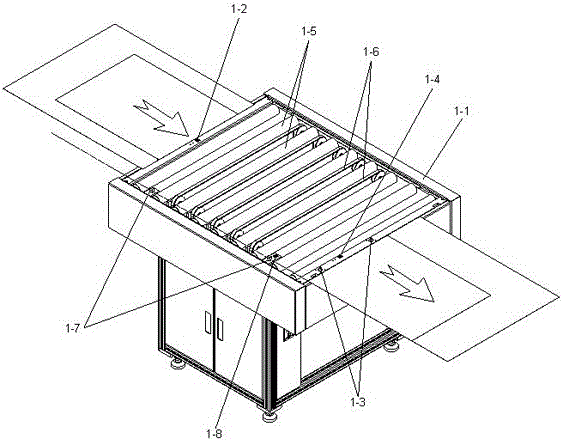

[0020] Such as figure 2 As shown, the plate entry correction mechanism 1 includes a first workbench 1-1, a first sensor 1-2 is provided on one end of the first workbench 1-1, and a first sensor 1-2 is provided on the other end of the first workbench 1-1. A plurality of first limit blocks 1-3 driven by the cylinder, a second sensor 1-4 is also provided on the other end of the first workbench 1-1, and a plurality of longitudinal sensors 1-4 are arranged on the first workbench 1-1. The first conveying roller 1-5 of rolling, the first conveying roller 1-5 is driven by motor, is provided with the first conveying belt 1-6 of a plurality of lateral transmissions between the first conveying roller 1-5, the first Conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com