Rotary bit change type rubber sieve perforating machine

A punching machine and rubber technology, applied in metal processing, etc., can solve the problems of time-consuming and laborious, many types of punching machines, and inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

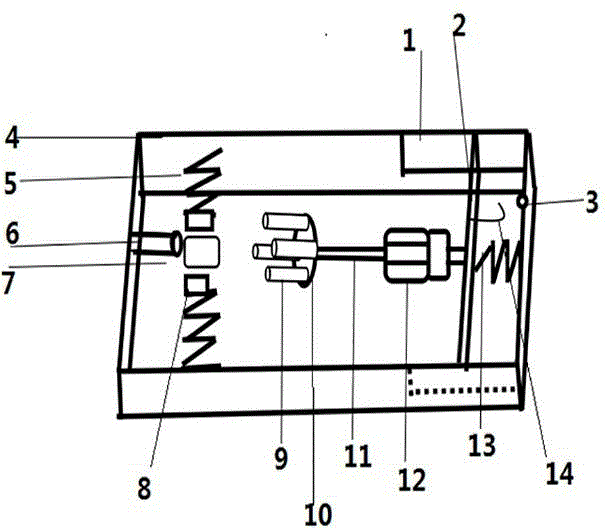

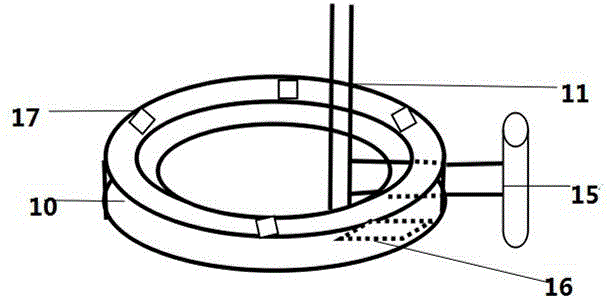

[0013] Such as Figure 1-Figure 2 As shown, the design consists of a chute 1, a baffle plate 2, a round hole 3, a casing 4, a spring a5, a pillar 6, a placement plate 7, a partition 8, a drill bit 9, a disc 10, a rotating rod 11, a motor 12, Spring b13, hook 14, knob 15, support plate 16, and scale value 17; the rubber stopper to be punched is placed horizontally on the placement plate 7, the right end of the rubber stopper is supported by the pillar 6, and the elastic force generated by the compression of spring b13 The rubber stopper is firmly clamped through the partition 8. According to the diameter of the stopper that needs to be drilled, look for the scale value 17 of the diameter on the disc 10, and rotate the drill bit 9 corresponding to the scale value 17 to the upper right of the rubber stopper. , tighten the knob 15, take the hook 14 out of the round hole 3, under the elastic force of the spring a5, the baffle plate 2 moves to the left in the chute 1 to make the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com