Machining mechanism for rail transit

A processing mechanism and rail transit technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient operation and many operators, achieve high accuracy, reduce manual operations, and high punching efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

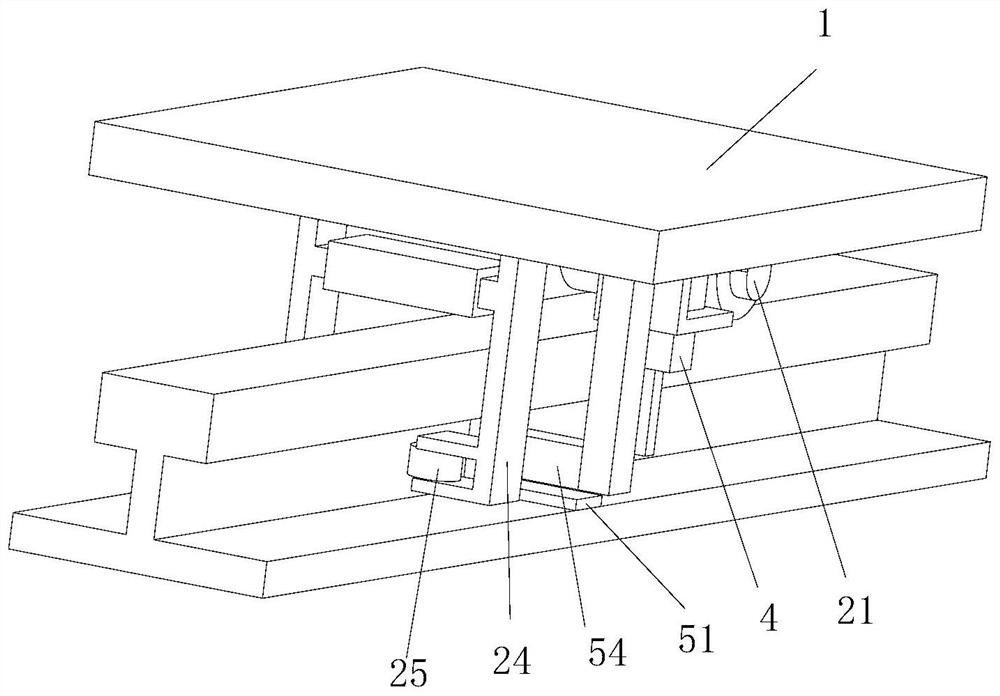

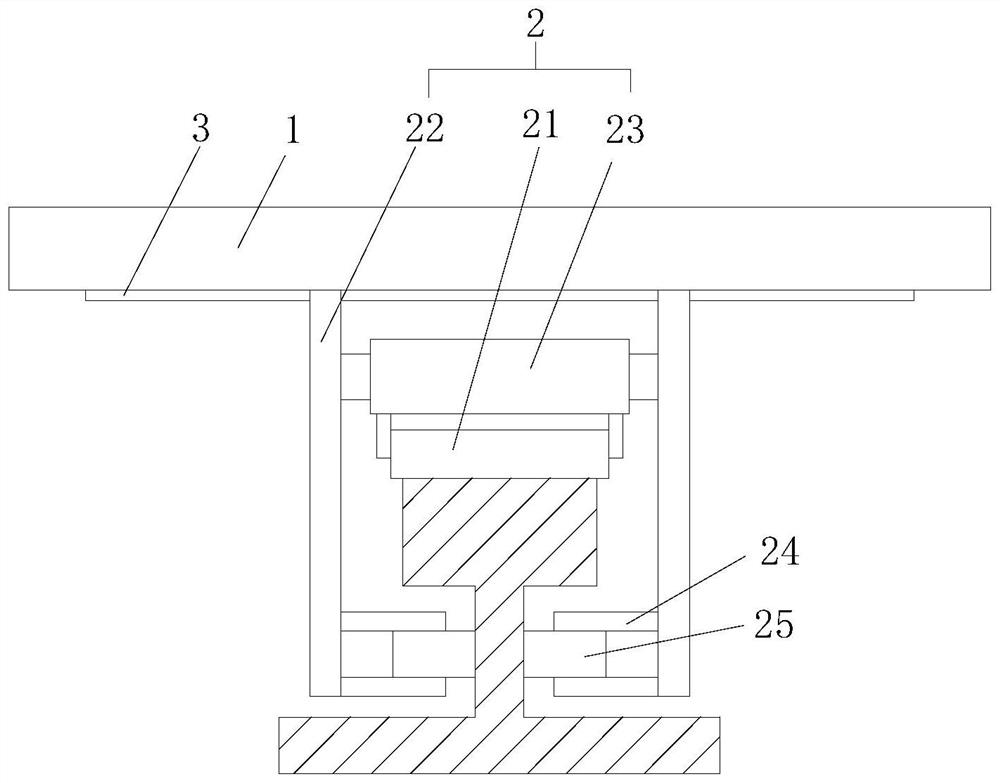

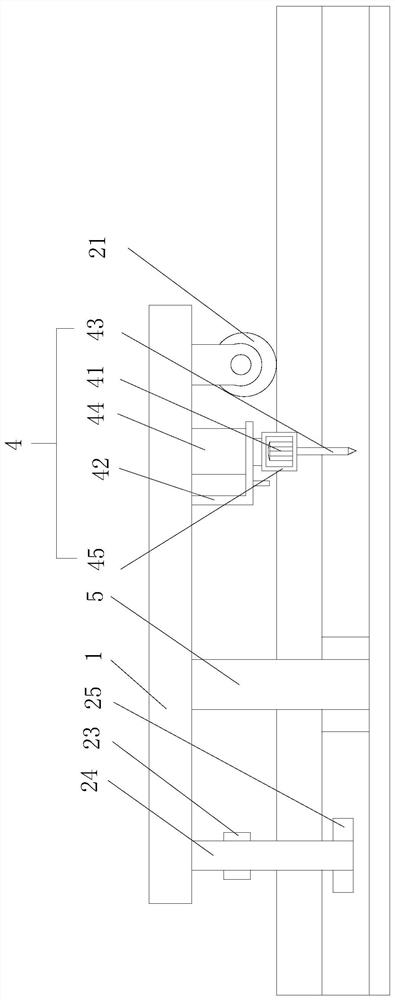

[0044] Attached below Figure 1-5 The present invention is further described with examples:

[0045] A processing mechanism for rail transportation, comprising a machine table 1, a self-propelled mechanism 2 is provided on one side of the bottom of the machine table 1, and the self-propelled mechanism 2 includes a suspension, the bottom of the suspension is rotatably mounted with a driving roller through a bearing 21. The driving roller 21 is driven by a motor and is in contact with the upper surface of the track; the bottom of the machine table 1 is provided with a drilling mechanism 4, which is used for drilling holes on the bottom panel of the track. The invention solves the problem that the drilling machines on the market generally need to manually operate the drilling machine to punch the steel rail, and the operation is inconvenient due to many operators. The drilling rig is directly installed on the track, and automatically travels to the preset position for positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com