Heat preservation plate perforating machine

A technology of punching machine and thermal insulation board, which is applied in metal processing, non-rotational vibration suppression, etc., can solve the problems of low punching efficiency, inconvenient operation, complicated working conditions on the construction site, etc., and achieves high punching efficiency and uniform punching. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

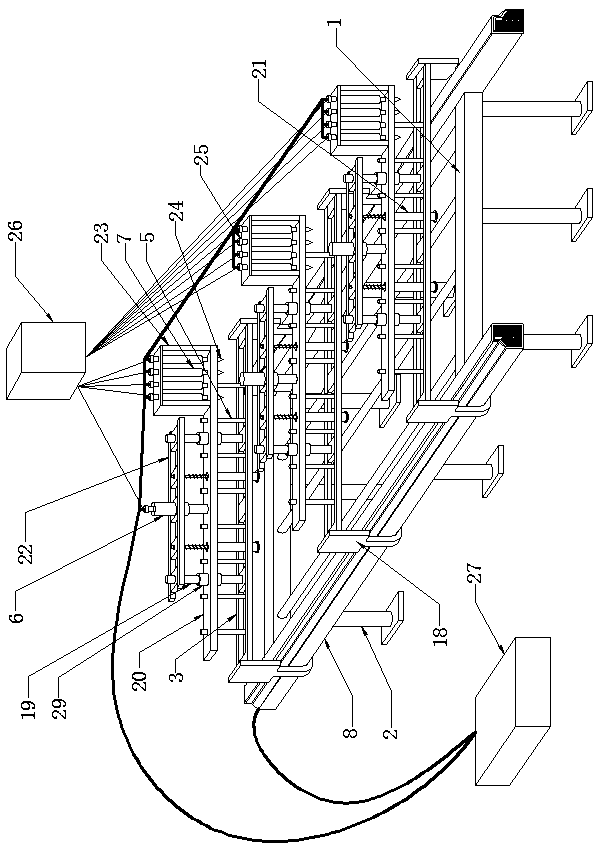

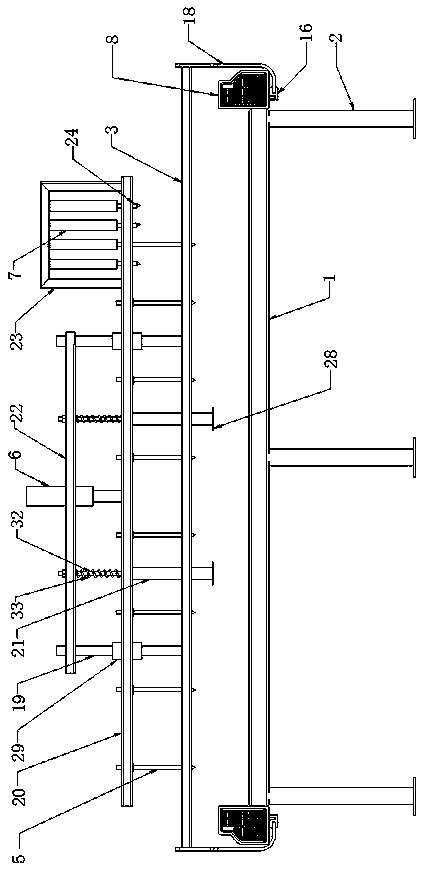

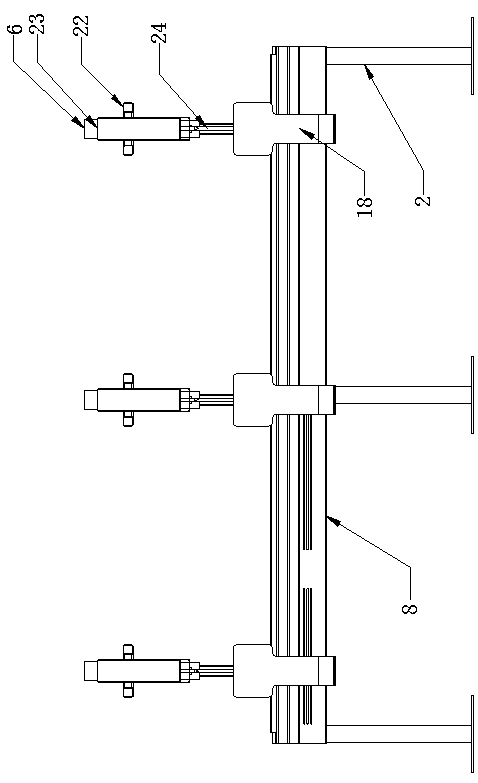

[0037] as attached Figure 1-10 As shown, a thermal insulation board punching machine includes a workbench 1, supporting legs 2, a lower beam 3, a longitudinal guide rail 4, a fixed punching cone 5, a stroke cylinder 6, and a telescopic cylinder 7. The lower part of the workbench 1 is provided with a support Legs 2, the legs 2 are fixed on the ground, rail housings 8 are fixed on both sides of the workbench 1, guide grooves 9 are provided at the bottom of the rail housing 8, longitudinal guide rails 4 are arranged inside the rail housing 8, and the A rack 10 is arranged on the top of the longitudinal guide rail 4, and a slide block 11 is installed on the longitudinal guide rail 4;

[0038] The upper part of the slider 11 is fixedly provided with a motor support 12, and a vertically arranged servo motor 13 is installed on the motor support 12, and a gear 14 is installed at the bottom of the servo motor 13, and the gear 14 is meshed with the rack 10; The lower part of the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com