Laser drilling method and laser drilling system

A laser drilling and laser beam technology, which is used in laser welding equipment, glass manufacturing equipment, welding/welding/cutting items, etc., can solve the problem of poor surface quality of hole processing and the inability of laser drilling method to adapt to ultra-high chemical strength substrate materials and other problems to achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to specific embodiments and accompanying drawings.

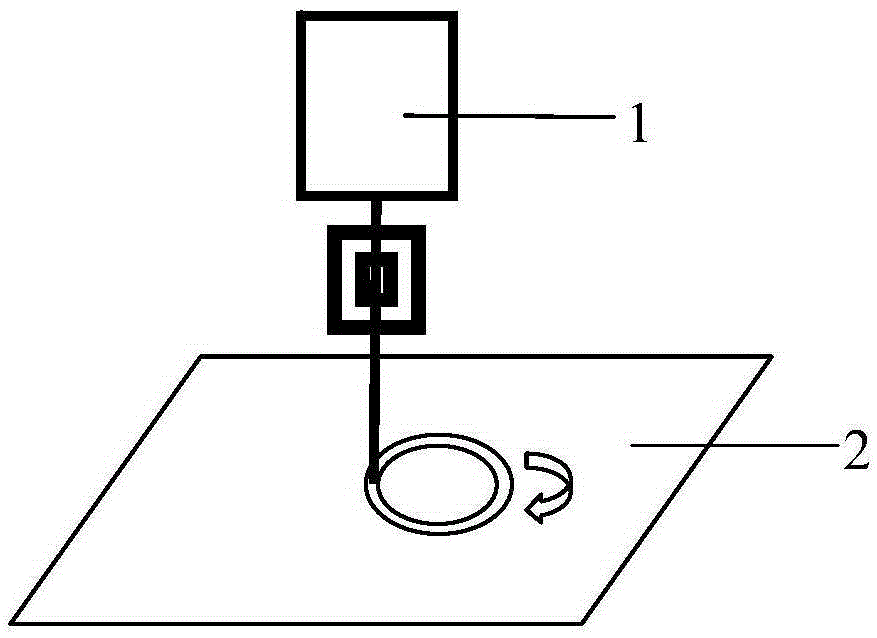

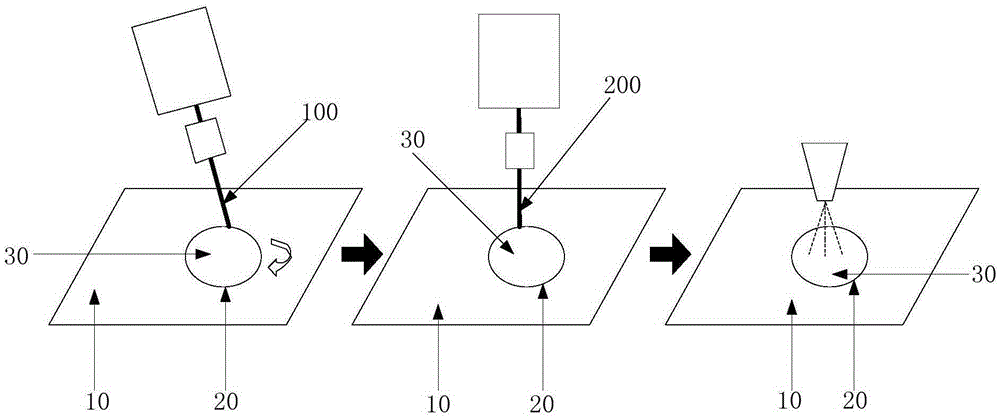

[0041] figure 2 It is a schematic structural diagram of the principle structure of the laser drilling method described in a specific embodiment of the present invention, combined with figure 2 , the laser drilling method described in a specific embodiment of the present invention, comprising:

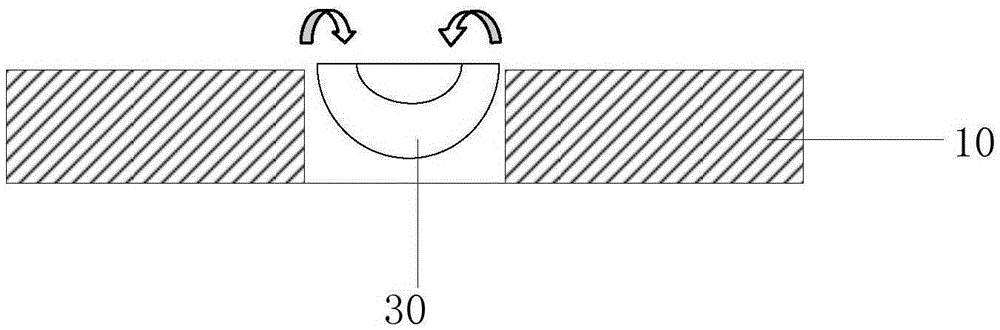

[0042] Step 1, hole boundary forming step: output pulsed laser beam 100, scan on the substrate 10 to be punched, and form the boundary cutting groove 20 of the preformed hole;

[0043] Step 2, material heating step in the hole: output CO 2 laser beam 200, making the CO 2 The laser beam 200 is aligned with the pre-formed hole, and the substrate material 30 of the pre-formed hole is heated for a predetermined time;

[0044] Step 3, hole forming step: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com