Hydraulic lifting-type pipe perforator

A hydraulic lifting and punching machine technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc. It can solve the problems of uncontrollable drill bit drilling, complicated drill bit mechanism, and low drilling efficiency. Problems, to achieve the effect of simple structure, strong operability, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

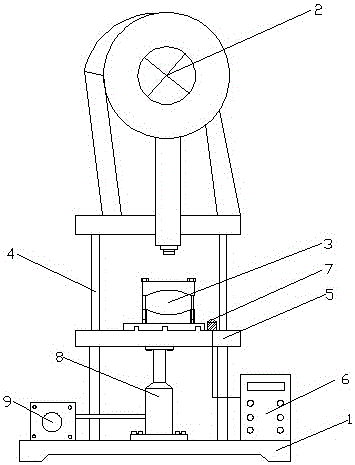

[0011] figure 1 It shows a structural schematic diagram of a pipe punching machine with a lifting device provided by the present invention, including a body 1, a processing part 2 and a clamping part 3 located on the body 1, and the feature is that the processing part 2 is a pipe punching machine. The drill part of the hole machine, the clamping part 3 is the part that clamps the pipe to be processed; the supporting guide post 4 is connected between the processing part 2 and the clamping part 3; the clamping part 3 is fixedly connected with a support plate 5 , the support plate 5 and the support guide post 4 are slidingly arranged, and the two sides of the support plate 5 are provided with holes matching the support guide post 4; the bottom of the support plate 5 is fixedly connected with a lifting device that driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com