Robot grinding system for outer surface of cylinder with boss

A technology of outer surface and robot, which is applied in the field of metal product processing, can solve the problems of low operation tasks, long processing time, grinding and processing troubles, etc., and achieve the effect of reducing labor intensity, improving production efficiency, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

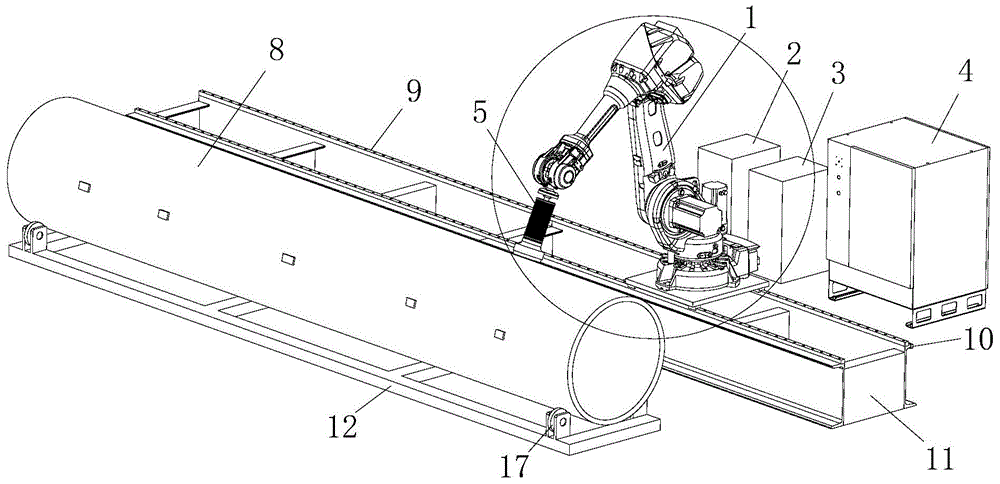

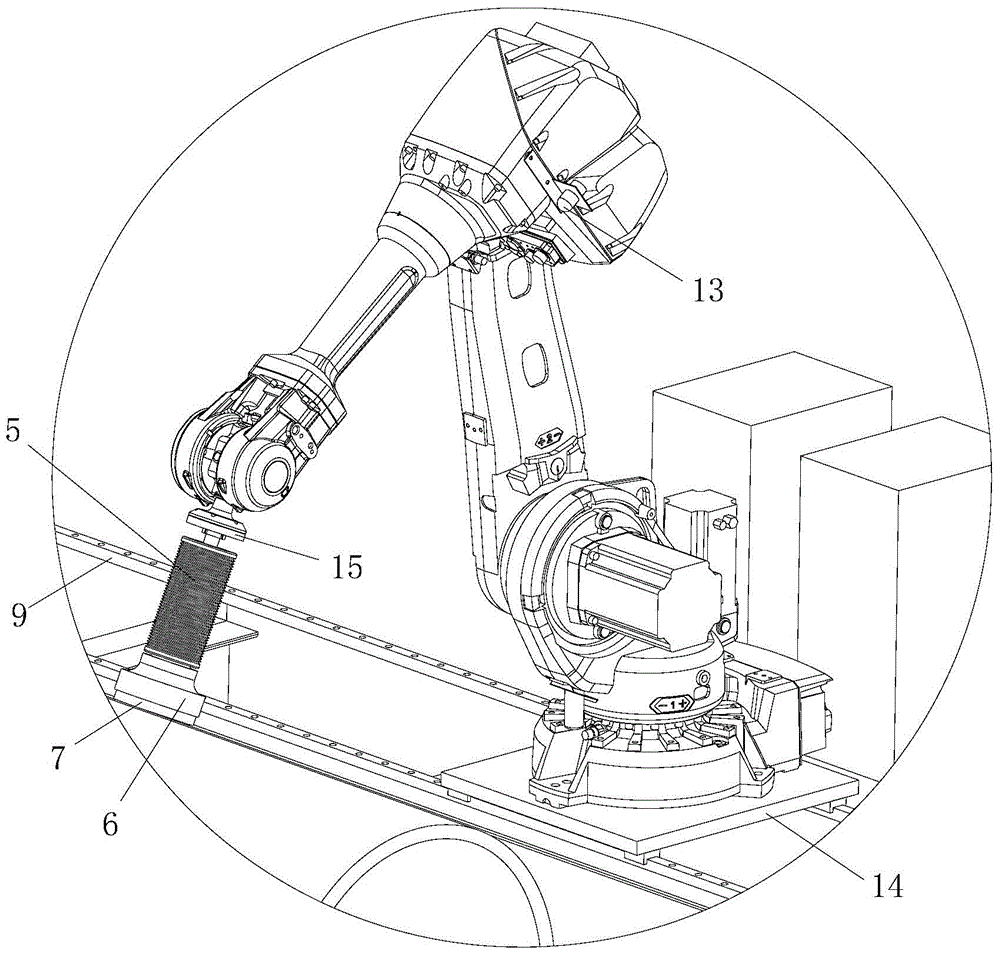

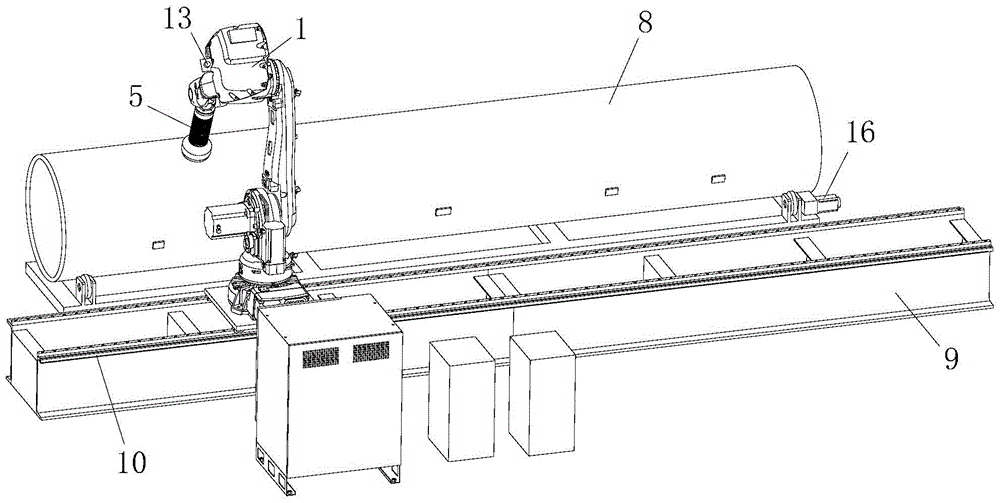

[0025] In this example, refer to figure 1 , figure 2 and image 3 , the robot grinding system for the outer surface of a cylinder with a boss includes,

[0026] Mobile track 11, is used for installing industrial robot 1;

[0027] The industrial robot 1 is installed on the moving track 11, and the forearm part of the industrial robot 1 is stretched to align with the workpiece 8 to be processed;

[0028] Robot control cabinet 2, connecting and controlling industrial robot 1;

[0029] The barostat 5 and the pneumatic control cabinet 3, the barostat 5 is installed on the front end of the forearm of the industrial robot 1, the pneumatic control cabinet 3 is connected to the barostat 5, and the pressure of the barostat 5 is controlled by a pneumatic circuit;

[0030] The electrical system control cabinet 4 is connected to the robot control cabinet 2 and the pneumatic control cabinet 3, and is used for offline calculation of the kinematics and dynamics of the industrial robot 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com