Porous surface layers with increased surface roughness and implants incorporating the same

a technology of surface roughness and porous structure, which is applied in the direction of prosthesis, packaging foodstuffs, packaging goods, etc., can solve the problems of loss of roughness on machined surfaces and mechanisms that have so far proved unsatisfactory in increasing roughness, so as to increase the surface roughness of machined tissue-interfacing, increase the surface roughness of porous structure, prevent the effect of pores occlusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

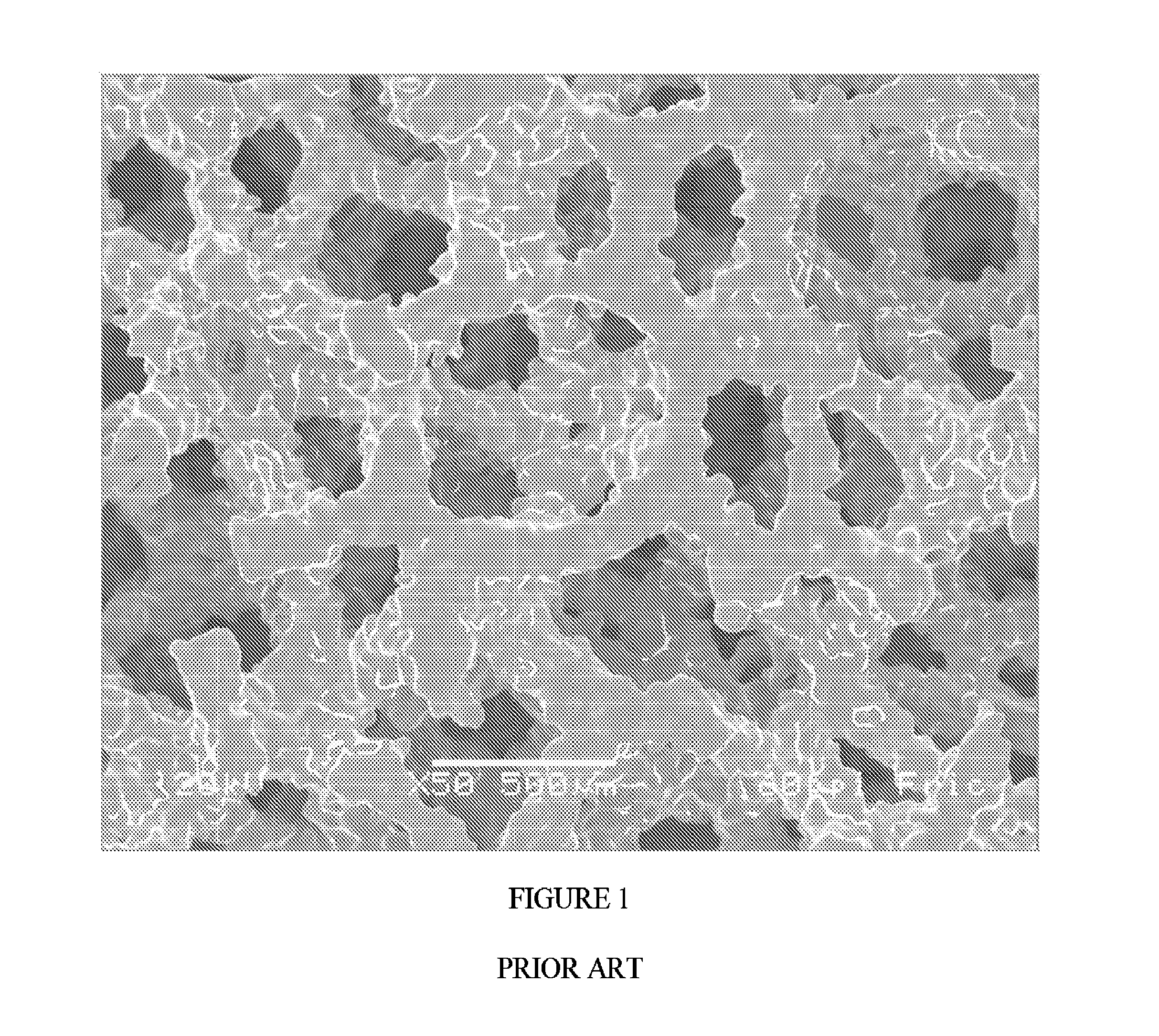

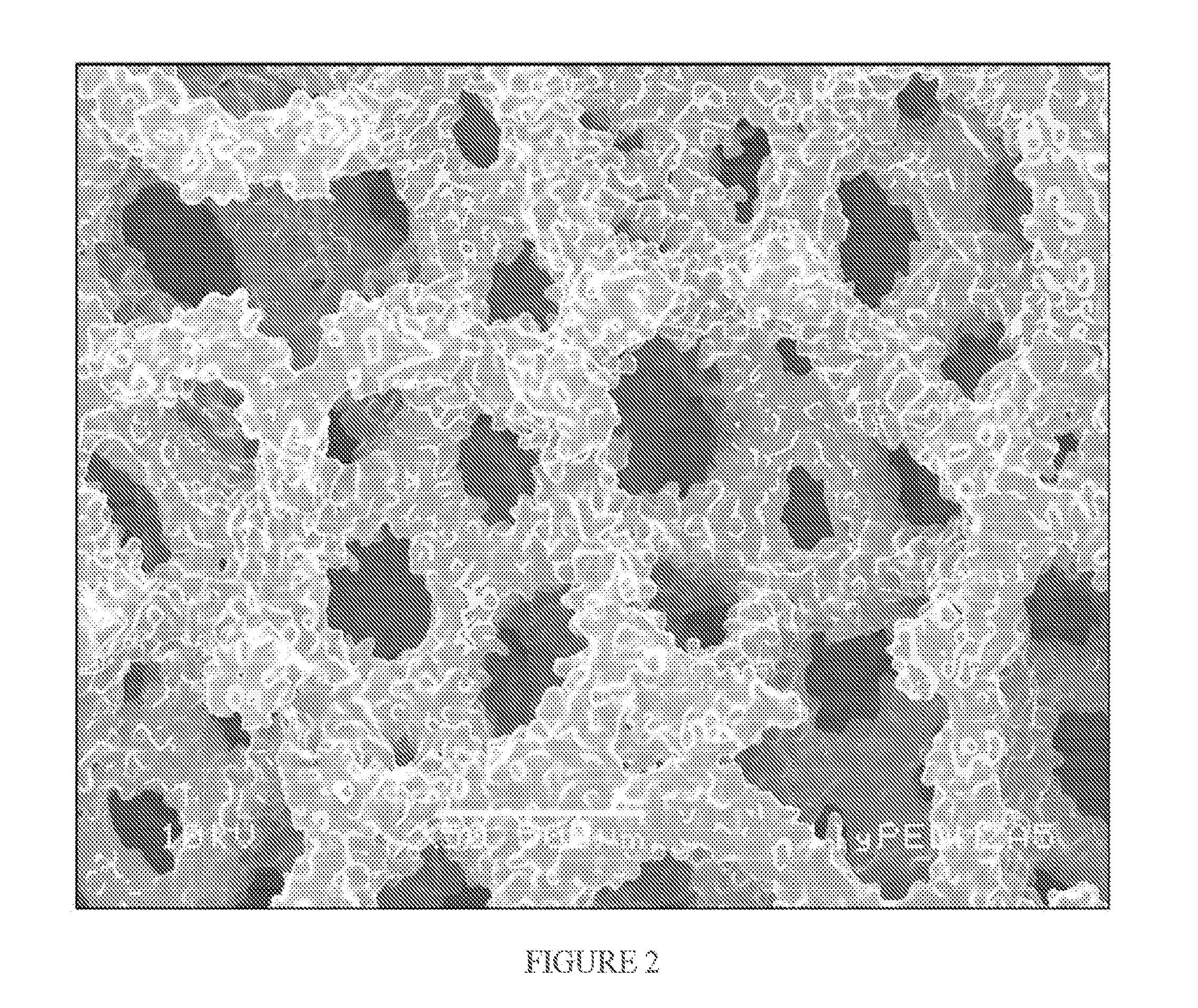

[0031]The embodiments disclosed herein provide a porous structure with increased surface roughness on a machined tissue-interfacing outer surface of the structure and methods of fabricating the same. The machined tissue-interfacing outer surface generally benefits from an increased roughness created by the application of a powder to a porous structure (e.g., porous metal body, porous foam material).

[0032]Generally, a tissue-interfacing outer surface with increased roughness can be applied to a porous metallic structure, a formed structure, the surface of a pre-formed structure, or some other object. In the case of medical articles, a bioinert material such as titanium, titanium alloys, tantalum, tantalum alloys, cobalt-chromium alloys, zirconium, zirconium alloys, and the like can be used for the porous structure. However, other suitable metallic and non-metallic materials can be used. Such non-metallic materials can include osteoconductive ceramics such as, for example, calcium pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com