Ceramic working surface damnification detecting system

A detection system, a technology for ceramic processing, applied in the direction of optical testing flaws/defects, etc., can solve the problems of reduced strength, scrap, surface tissue damage, etc., to achieve low cost, large economic benefits, and reliable and effective promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] After grinding, the surface processing damage caused by the grinding force and grinding temperature on the ceramic surface will directly affect the fatigue strength, fracture strength, surface hardness and wear resistance of the part, and it is also an important cause of surface cracks and surface breakage. When discussing the two important factors that affect the integrity of the surface, the surface mechanical performance index and surface morphology are analyzed. Experiments are designed to grind a variety of ceramic materials under different grinding conditions to obtain the ground surfaces under different conditions. Systematic theoretical analysis and experimental research on the processing damage of the ceramic surface after grinding are done.

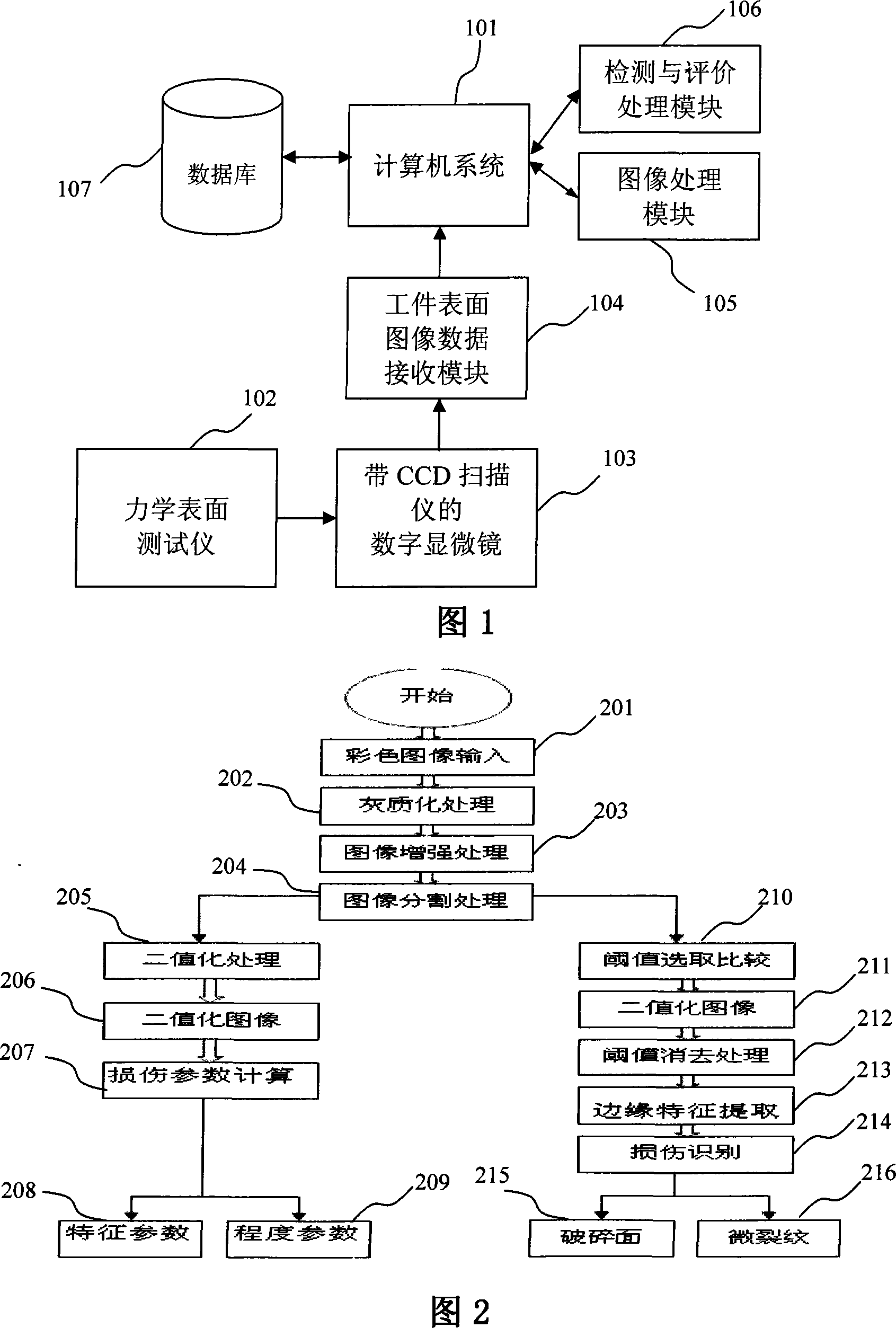

[0016] The invention uses computer digital image processing technology and development tools to process the collected surface images of workpieces for various defects of the processed surface / subsurface in the high-effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com