High hardness stainless steel feedstock and preparation method thereof, high hardness stainless steel blank and preparation method thereof

A stainless steel, high hardness technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor thermal stability, low degreasing efficiency, low hardness, etc., achieve high thermal stability, high degreasing efficiency, and improve hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

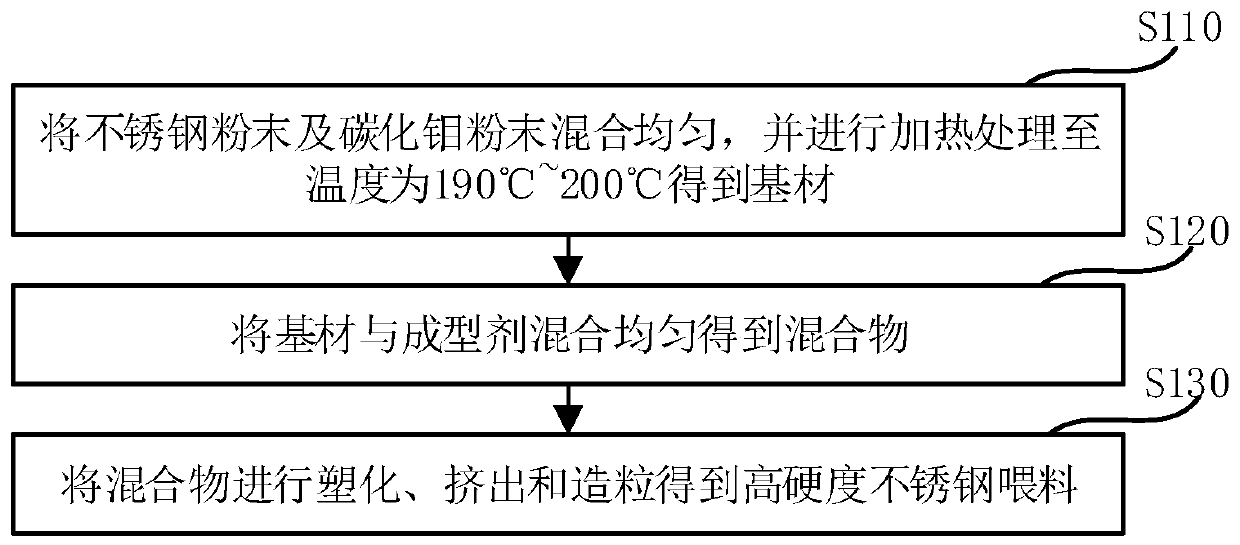

[0044] see figure 1 , the preparation method of the high-hardness stainless steel feeding material of one embodiment, comprises the following steps:

[0045] S110, uniformly mixing the stainless steel powder and the molybdenum carbide powder, and performing heat treatment until the temperature is 190° C. to 200° C. to obtain a base material.

[0046] In one embodiment, the stainless steel powder and the molybdenum carbide powder are mixed by stirring in a kneader, and the stirring rate is 4r / min-6r / min.

[0047] Heat treatment of stainless steel powder and molybdenum carbide powder to 190°C to 200°C can remove the moisture in the base material.

[0048] In one embodiment, the time for mixing the stainless steel powder and the molybdenum carbide powder is 1 hour to 2 hours.

[0049] S120, uniformly mixing the base material and the molding agent to obtain a mixture.

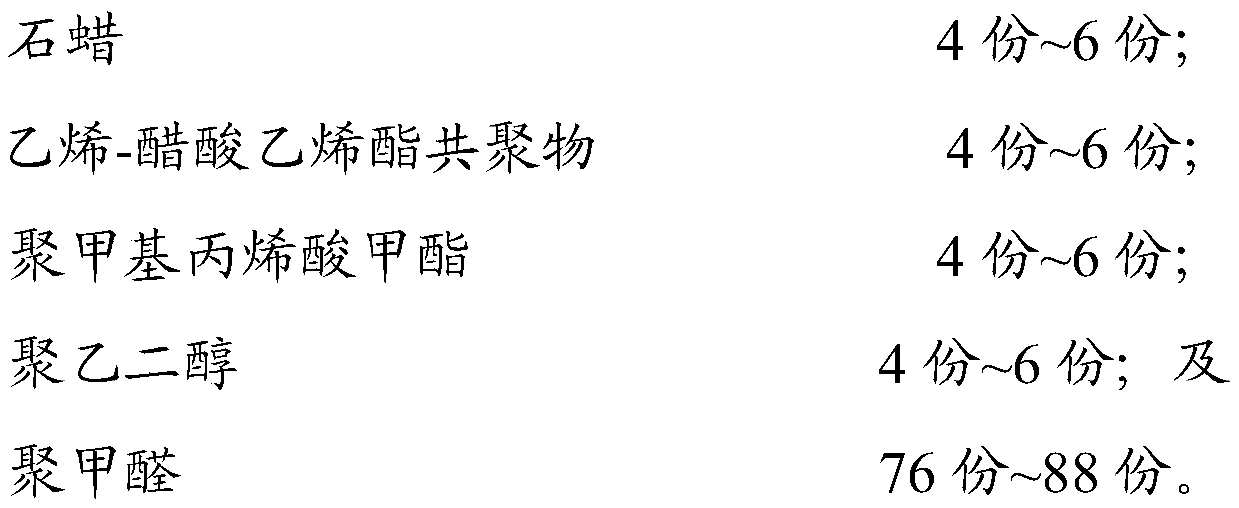

[0050] In one embodiment, the forming agent is added into the heated base material and mixed until it becomes...

Embodiment 1

[0069] Weigh 4.4Kg of SUS316L stainless steel powder and 0.09Kg of molybdenum carbide powder into a kneader, heat to 200°C and mix for 1 hour to obtain the base material. During the mixing process, the speed of the kneader is set to 5r / min.

[0070] Among them, the particle size of molybdenum carbide is 80nm; when the temperature of the detection substrate is greater than 170°C, add 0.025Kg of No. 58 fully refined paraffin wax, 0.02Kg of ethylene-vinyl acetate copolymer, and 0.027Kg of polymethyl ether to the kneader. Methyl acrylate, 0.025Kg of polyethylene glycol and 0.38Kg of polyoxymethylene were mixed to a muddy mass, wherein the mixing process made the temperature 185°C, the mixing speed was 20r / min, and the mixing time was 30min, and then stop the mixing process. Heating the substrate and molding agent, and continuing to mix for 30 minutes to obtain a mixture; put the mixture into a twin-screw extruder for plasticization and extrusion, and then granulate in a granulator ...

Embodiment 2

[0073] Weigh 9.4Kg of SUS316L stainless steel powder and 0.1Kg of molybdenum carbide powder into a kneader and heat to 190 ° C for 2 hours to obtain the base material. The diameter is 10nm; when the temperature of the detection substrate is greater than 170°C, add 0.03Kg of No. 58 fully refined paraffin wax, 0.03Kg of ethylene-vinyl acetate copolymer, 0.03Kg of polymethyl methacrylate, 0.03 Kg of polyethylene glycol and 0.38Kg of polyoxymethylene are mixed to a muddy mass, wherein the mixing process makes the temperature 180°C, the mixing speed is 30r / min, and the mixing time is 60min, and then stop the mixing of the substrate and the forming agent. Heat and continue mixing for 20 minutes to obtain a mixture; put the mixture into a twin-screw extruder for plasticization and extrusion, and then granulate in a granulator to obtain a high-hardness stainless steel feed.

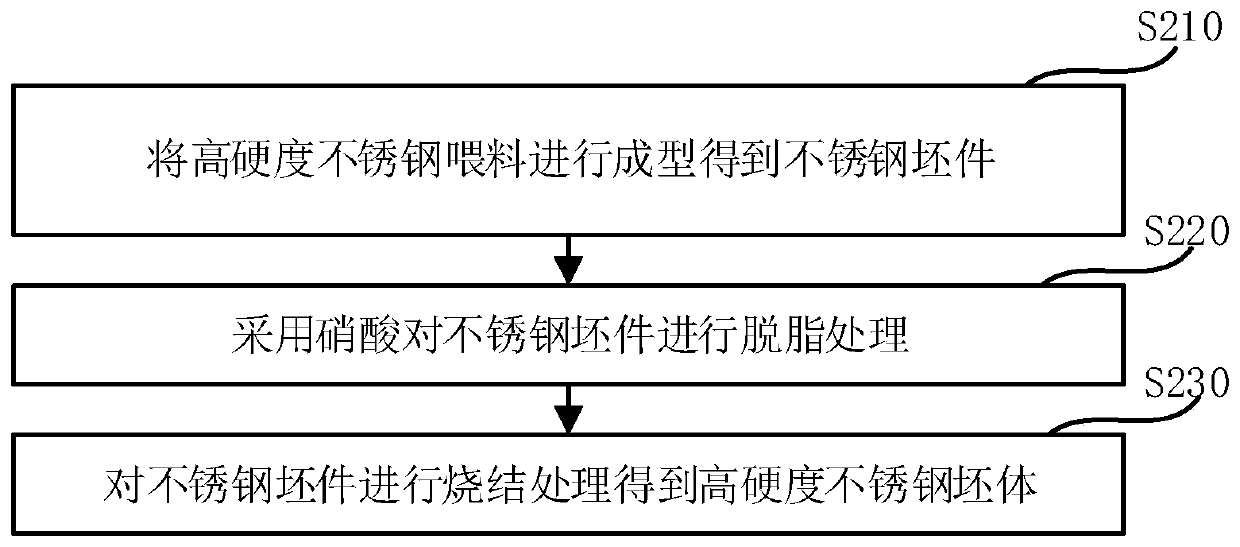

[0074] The product mold is selected and installed in the injection molding equipment, and the high-hardness st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com