Large-scale plate-fin heat exchanger core body high-temperature brazing and flexible bundling device and method

A technology of plate-fin heat exchangers and strapping devices, which can be used in auxiliary devices, welding equipment, metal processing equipment, etc., and can solve problems such as fixture deformation and pre-tightening force relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

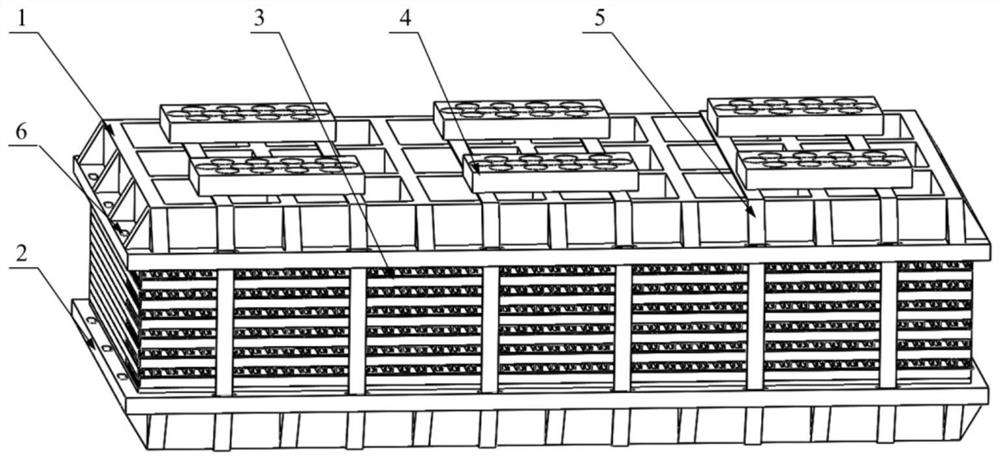

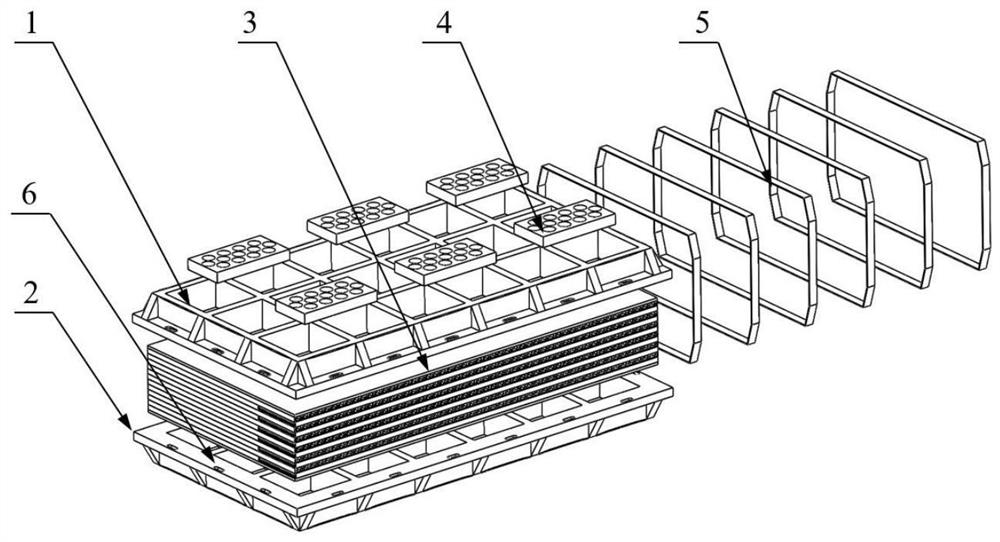

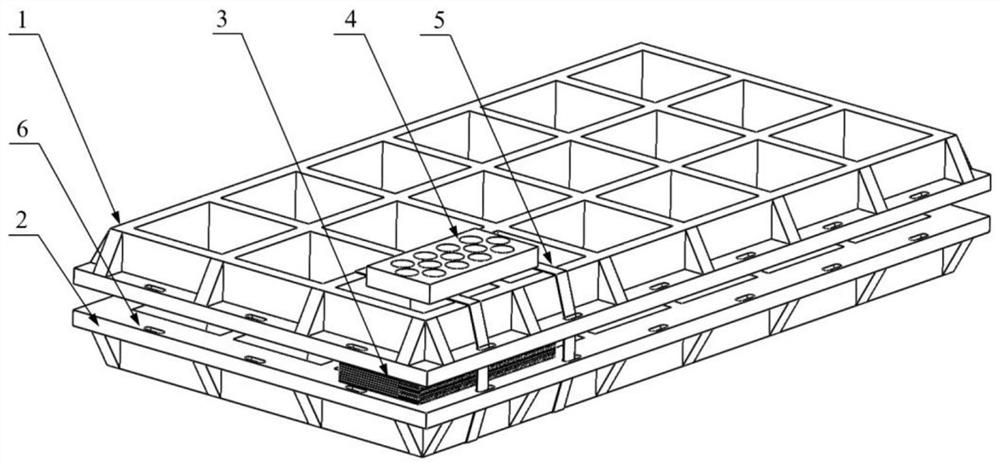

[0032] Refer Figure 1 to 5 As shown, the large-plate fin heat exchanger core of the present embodiment is a high-temperature brazing flexible strapping device including the upper splint 1, the lower pinch plate 2, the brazing unit 3, the compensation block 4, and the steel strip 5, which are combined. Removable structure.

[0033] Among them, regarding the brazing unit 3: Spread the heat exchanger core into a plurality of brazing units 3 according to the size of the heat exchanger core to be brazed, and the plurality of brazing units 3 after brazing are welded or The manual argon arc welding is welded into the core to meet the assembly requirements of different sizes of heat exchanger core.

[0034] A pre-assembled brazing unit 3 is placed between the upper splints 1 and the lower splint 2, and the three form a sandwich structure, the sandwich struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com