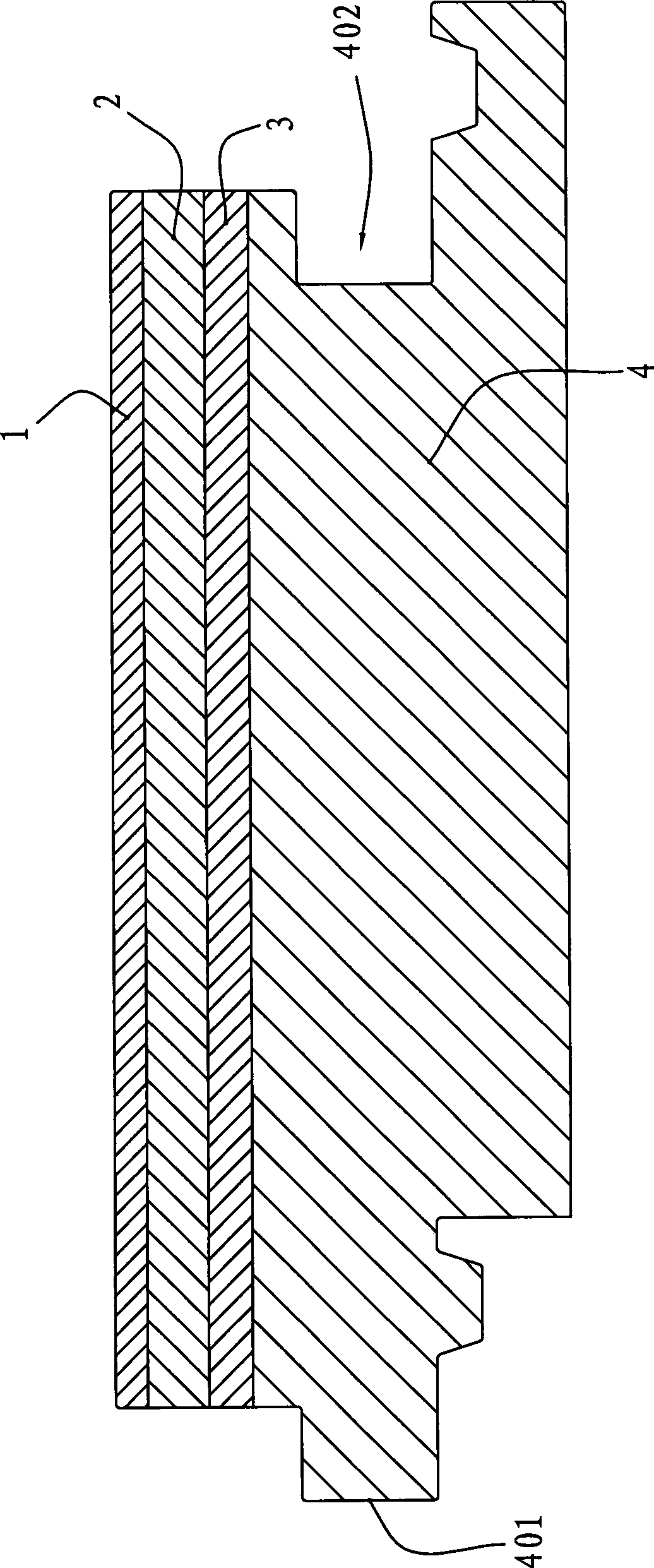

Composite floor board and method for producing the same

A composite floor and mixed layer technology, which is applied in the direction of manufacturing tools, floors, wood processing appliances, etc., can solve the problems of complex manufacturing process and high cost, and achieve the effects of convenient manufacturing and installation, low cost and saving of solid wood raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First of all, the wear-resistant impregnated paper containing aluminum oxide purchased from the general building materials market is laid on the surface of natural veneer, and then hot-pressed at 168°C to make the two firmly bonded to obtain a composite surface.

[0025] Secondly, fully stir the polyethylene and wood fibers and heat them to 160°C, and extrude them according to a predetermined thickness to obtain a wood-plastic mixed layer. Wherein, the particle size of wood fiber is 80 mesh. In the mixed layer, the percentage by weight of polyethylene is 30%.

[0026] Again, keep the temperature of the obtained wood-plastic mixed layer at 100°C, and lay an ethylene vinyl acetate copolymer resin layer with a temperature of 110°C on the surface of the mixed layer by extrusion to obtain an intermediate slab.

[0027] Finally, keep the temperature of the aforementioned intermediate slab at 100°C, lay the previously obtained composite surface layer on the surface of the eth...

Embodiment 2

[0029] First of all, the wear-resistant impregnated paper containing aluminum oxide purchased from the general building materials market is laid on the surface of natural veneer, and then hot-pressed at 180°C to make the two firmly bonded to obtain a composite surface.

[0030] Secondly, fully stir the polypropylene and crop straw fibers and heat them to 180°C, and extrude according to a predetermined thickness to obtain a wood-plastic mixed layer. Wherein, the grain size of the crop straw fiber is 160 mesh. In the mixed layer, the weight percentage of polypropylene is 50%.

[0031] Again, keep the temperature of the obtained wood-plastic mixed layer at 110°C, and lay an ethylene ethyl acrylate copolymer resin layer with a temperature of 115°C on the surface of the mixed layer by extrusion to obtain an intermediate slab.

[0032] Finally, keep the temperature of the aforementioned intermediate slab at 140°C, lay the previously obtained composite surface layer on the surface o...

Embodiment 3

[0034] First of all, the wear-resistant impregnated paper containing aluminum oxide purchased from the general building materials market is laid on the surface of natural veneer, and then hot-pressed at 208°C to make the two firmly bonded to obtain a composite surface.

[0035] Secondly, the mixture of polyvinyl chloride, wood fiber and crop straw fiber is fully stirred and heated to 220°C, and extruded according to a predetermined thickness to obtain a wood-plastic mixed layer. Among them, the particle size of wood fiber and crop straw fiber is 220 mesh. In the mixed layer, the percentage by weight of polyvinyl chloride is 70%.

[0036] Again, keep the temperature of the obtained wood-plastic mixed layer at 120° C., and lay a polyamide resin layer with a temperature of 120° C. on the surface of the mixed layer by extrusion to obtain an intermediate slab.

[0037] Finally, keep the temperature of the aforementioned middle slab at 180°C, lay the previously obtained composite s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com