Pressure line of high performance plastic steel thin wood composite door and window

A high-performance, wire-pressing technology, applied in the direction of window/door frame, wing frame, etc., can solve the problems of high price, shortened service life, and increased production cost of doors and windows.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

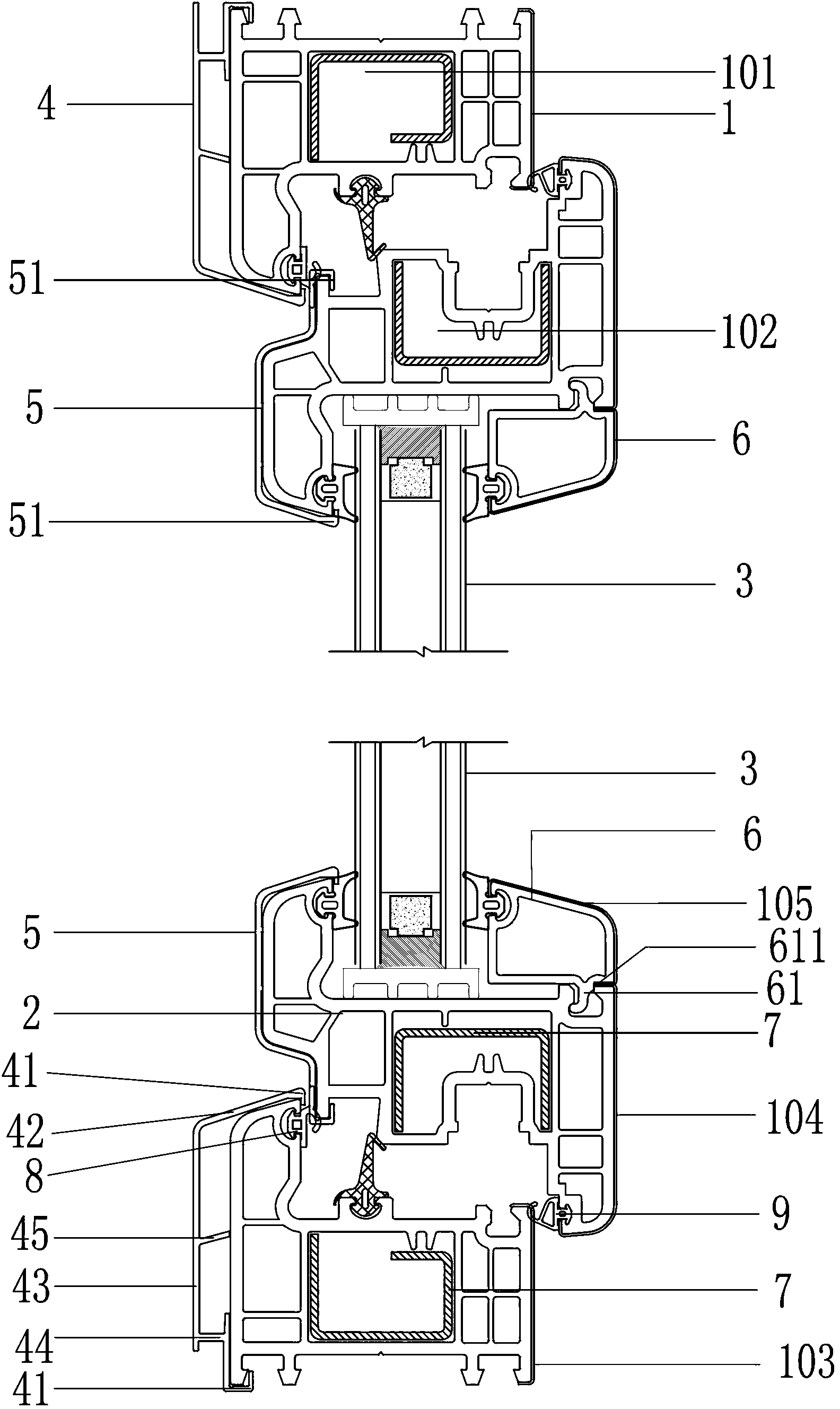

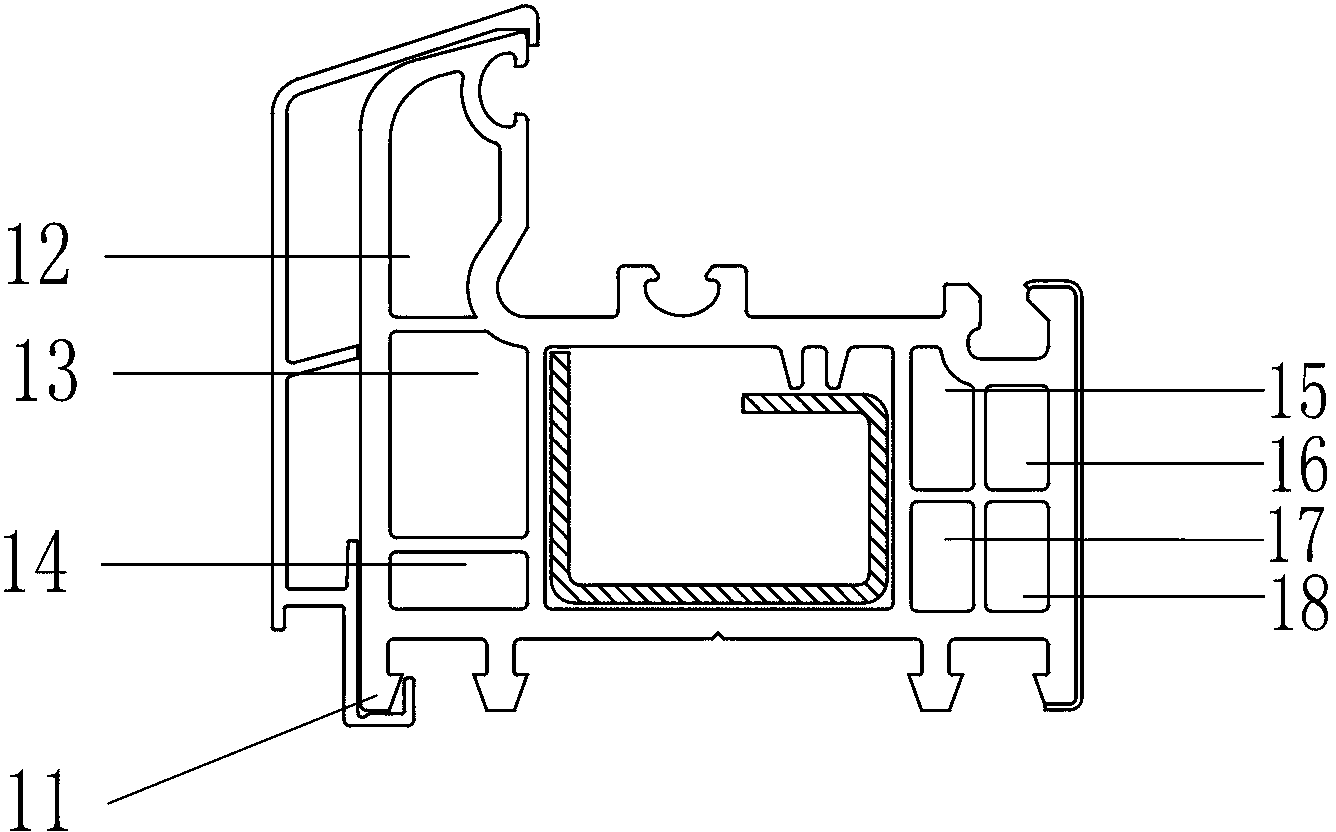

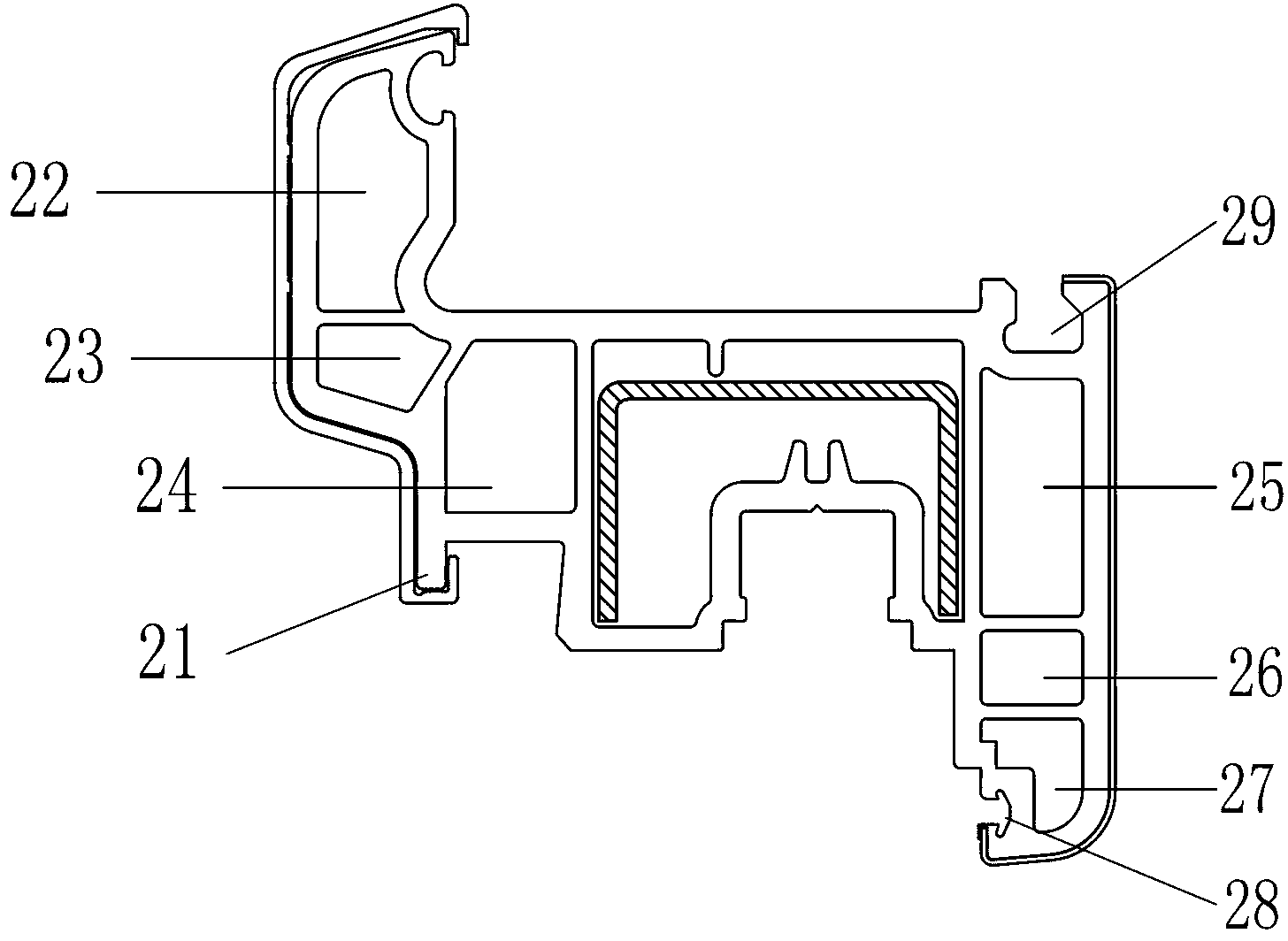

[0012] Hereinafter, in conjunction with the accompanying drawings, a detailed description will be given of the preferred embodiment of the pressing line of a high-performance plastic steel thin wood composite door and window of the present invention:

[0013] Such as figure 1 , figure 2 , image 3 A high-performance plastic-steel thin wood composite door and window shown includes frame material 1, fan material 2, frame material edge 4, fan material edge 5, press line 6 and glass 3. Frame material 1 and fan material 2 are respectively made of PVC profiles; The frame material 1 has a first transverse arm and a vertical arm. The front section of the frame material 1 is "L" from the indoor side to the outdoor side. A heat preservation cavity is provided in the middle of the frame material 1, and the outdoor side of the first transverse arm faces One side of the wall is provided with a first protruding strip 11, the outer side of the vertical arm is composed of connected vertical surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com