modular house

A modular and housing technology, applied in building materials, building components, wine cellars, etc., can solve the problems of high load-bearing requirements, large construction waste, and high transportation costs, and achieve transportation cost savings, light weight, and construction waste reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

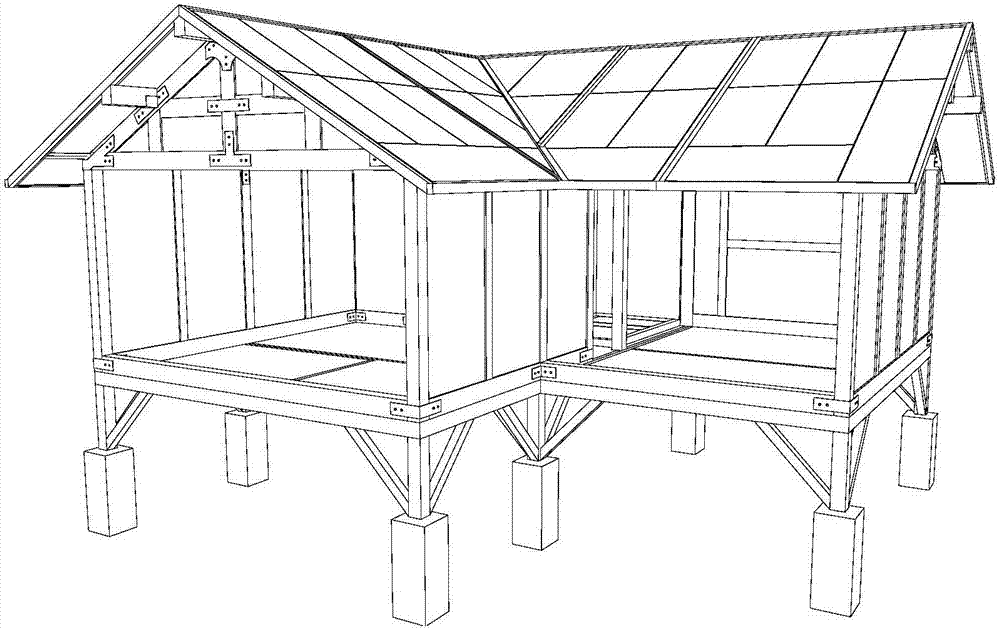

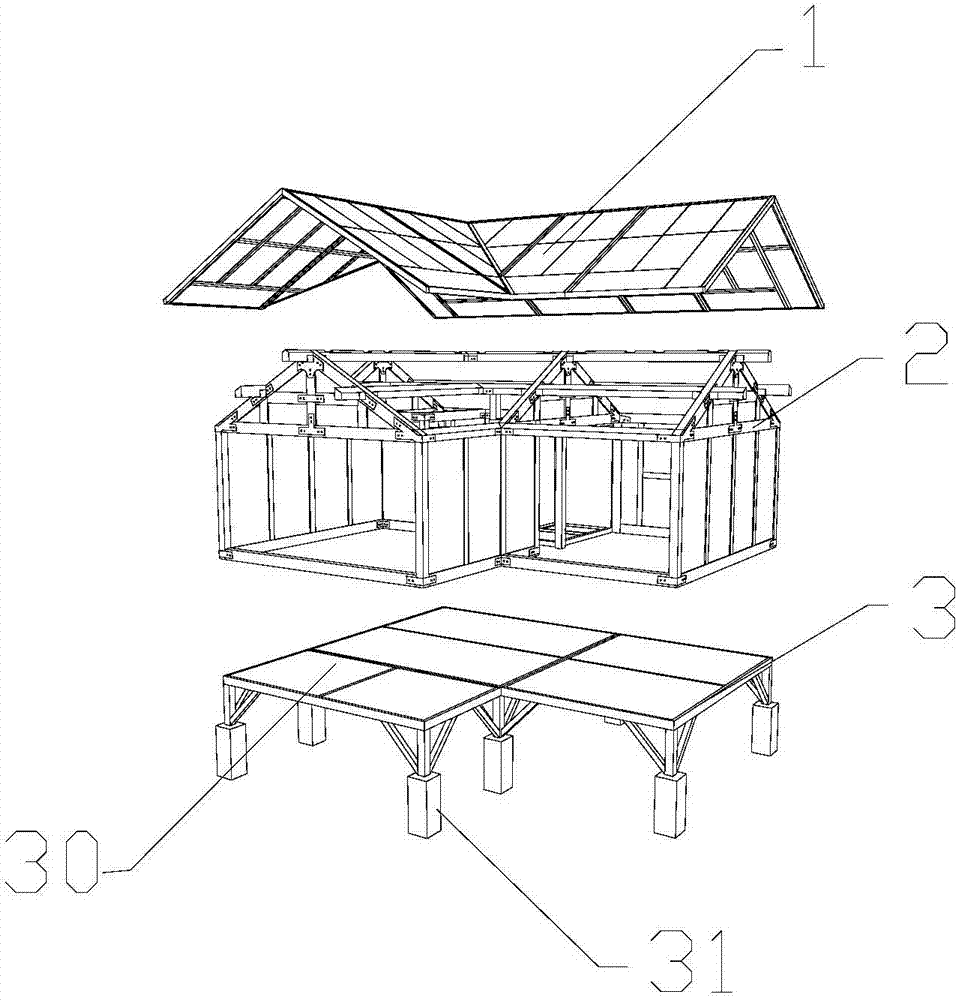

[0050] figure 1 It is a structural schematic diagram of a house using a modular house in one embodiment of the present invention. figure 2 Yes figure 1 An exploded view of the house in . combine figure 1 and figure 2 It can be seen that the house in this embodiment includes a roof 1, a modular wall body 2 and a base 3; wherein the base 3 includes a floor 30 and a supporting base 31 for supporting the floor.

[0051] The modularized integrated floor slab of the present invention is prefabricated in blocks according to the house design, and then each floor slab is combined and assembled to form a complete floor slab 30 .

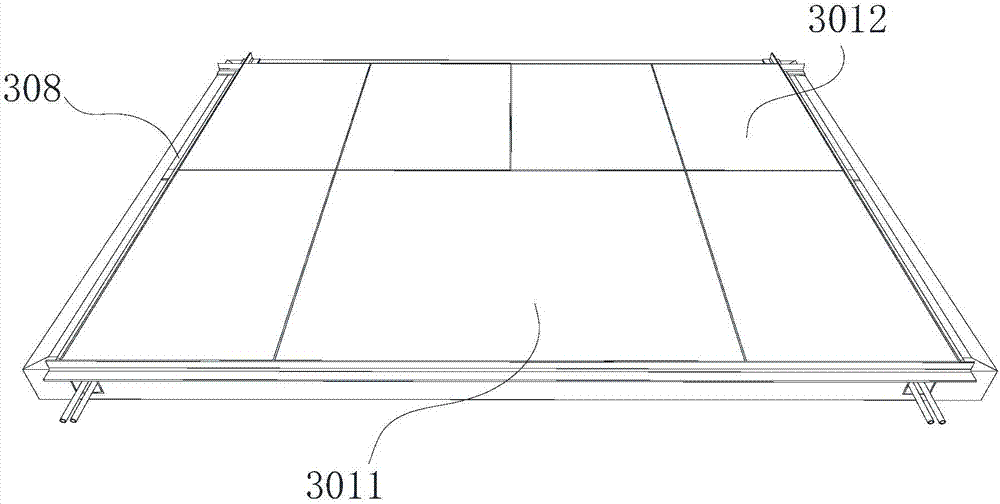

[0052] image 3 Yes figure 1 Schematic diagram of the modular integrated floor slab in . Figure 4 Yes image 3 A semi-disassembled schematic diagram of the modular integrated floor slab in . Figure 5 Yes image 3 An exploded schematic of the modular integrated floor slab in . Image 6 Yes image 3 The schematic diagram of the cooperation betwe...

Embodiment 2

[0068] Figure 8 Yes figure 1 Schematic diagram of the structure of the modular wall. Figure 9 Yes figure 1 Schematic diagram of the disassembly of the modular wall in . Figure 10 Yes figure 1 The disassembled diagram of another angle of the modular wall in . Figure 11 Yes figure 1 Schematic diagram of the structure of Zhongfang Decoration Wall Panel.

[0069] combine Figure 8 , Figure 9 , Figure 10 and Figure 11 It can be seen that for modular walls, each wall is pre-made in blocks according to the design. Wherein the wall body in this embodiment includes a wall body frame 21 and a decoration-free wallboard 22 .

[0070] A gap is provided between the wall body frame 21 and the decoration-free wallboard 22 . Setting this gap can avoid deformation due to thermal expansion and contraction. Generally, the width of the gap is 0.1-1 cm, preferably, the width of the gap is 0.3-0.5 cm.

[0071] Further, the elastic sealing material 23 is filled in the gap, and th...

Embodiment 3

[0085] Figure 12 It is the structural representation of the decoration-free wallboard in embodiment 3.

[0086] Figure 12 It is the structural representation of the decoration-free wallboard in embodiment 3. like Figure 12 As shown, the main body of the decoration-free wallboard 22 in this embodiment includes two layers, wherein the upper layer is chemically foamed concrete 222, and the lower layer is physically foamed concrete 223, wherein the upper surface of the chemically foamed concrete is provided with a protective layer 221.

[0087] The decoration-free wallboard 22 in this embodiment is prepared by the following method:

[0088] Step a, making a mold frame according to the design size, the mold frame includes a bottom plate and a frame with a certain height;

[0089]Step b: Pour the mixed puffed microbead mixture and foamed concrete slurry into the mold frame to a predetermined thickness; shake the poured slurry and level it; wait for the slurry to reach a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com