Preparation method of biomass composite material and application thereof

A technology of biomass materials and composite materials, applied in applications, other household appliances, wood treatment, etc., can solve problems such as unfavorable human health, easily damaged texture layer, unusable products, etc., achieve large-scale industrial application prospects, and have environmental protection Sexuality and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

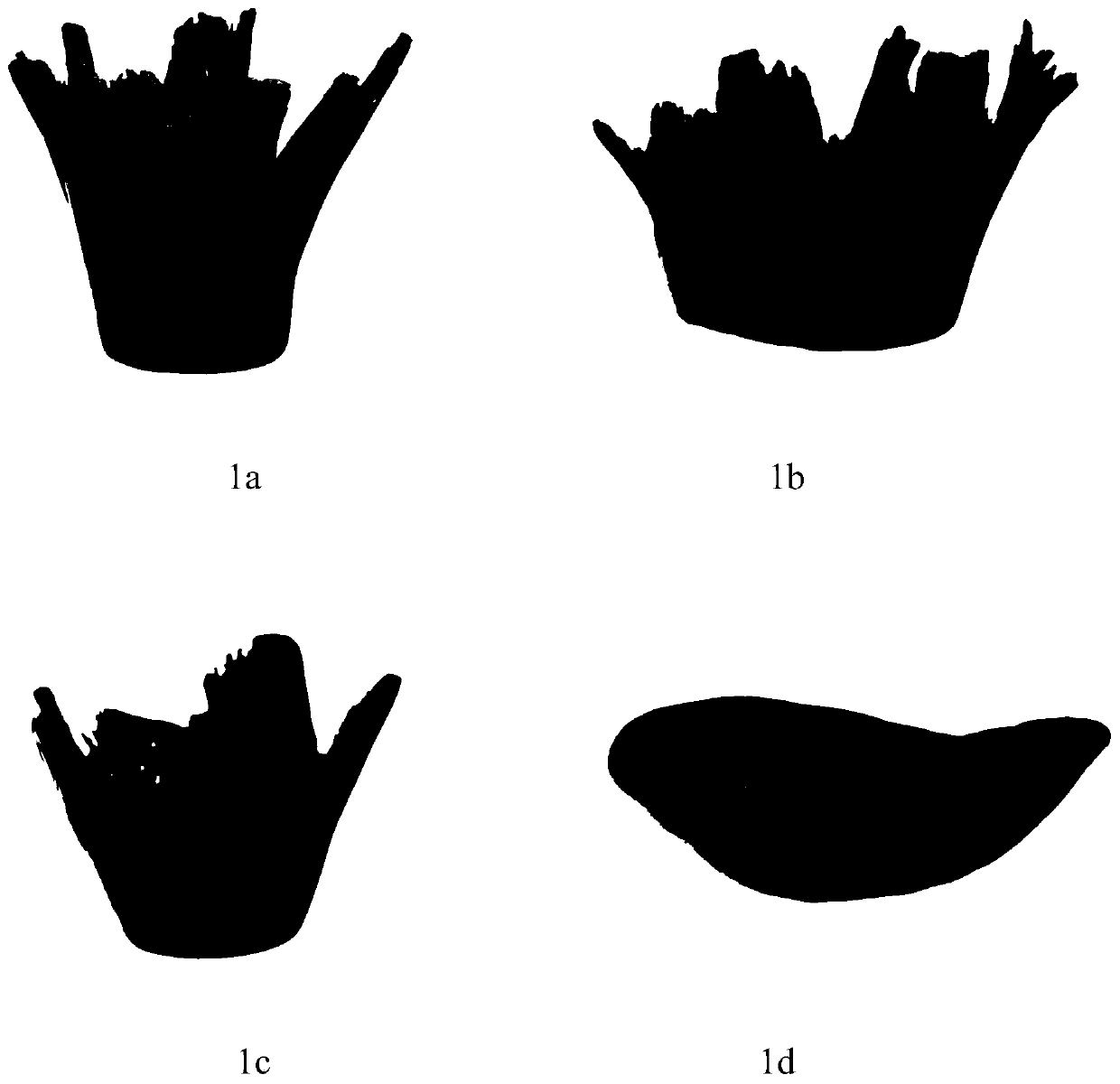

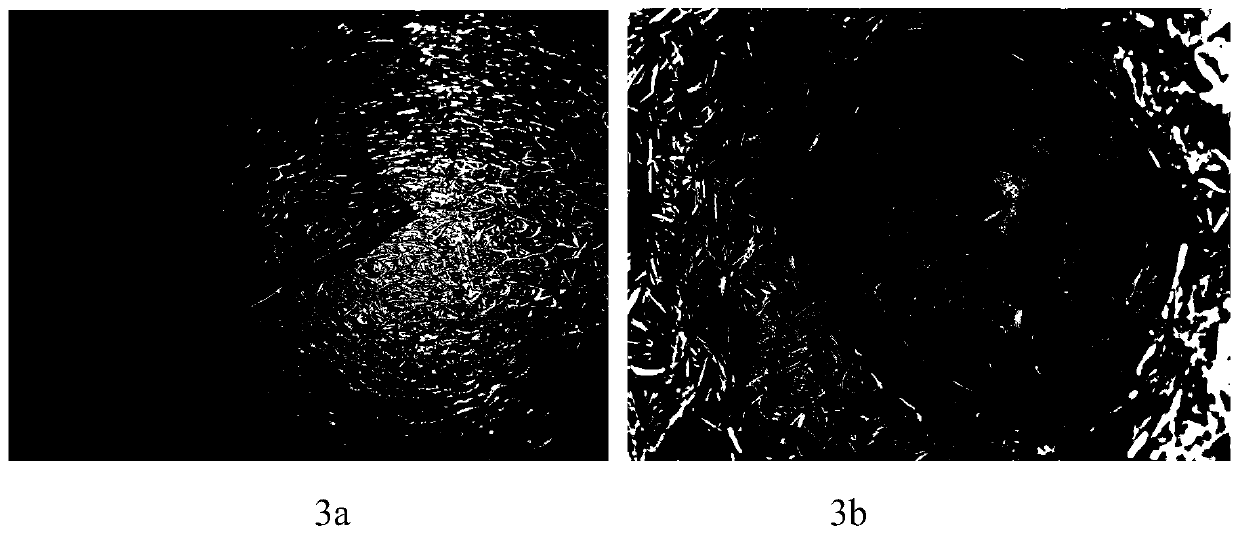

Image

Examples

Embodiment 1

[0033] A method for preparing a biomass container, comprising the steps of:

[0034] (1) Cleaning: Utilize clear water to wash away the mud etc. on the straw;

[0035] (2) Soaking: Soak the cleaned stalks in clear water for 24 hours at room temperature;

[0036] (3) Grinding: putting the soaked stalks into a grinding machine for grinding to obtain fibers with a length of 3 cm;

[0037] (4) dry; the straw fiber that step (3) obtains is placed 2d under the state of natural ventilation;

[0038] (5) Mixing: the dried straw and the biomass adhesive are mixed according to a mass ratio of 2.0:1.0 to form a compact, and the obtained compact is a biomass composite material;

[0039] (6) Then, under the condition of temperature of 90°C, hot press forming is carried out at a pressure of 4.0MP, and the hot pressing time is 300s, and then several times of repairing, polishing and surface waterproof treatment are carried out to obtain a biomass container.

[0040] In this embodiment, th...

Embodiment 2

[0043] A method for preparing a biomass container, comprising the steps of:

[0044] (1) Cleaning: Utilize clear water to wash away the mud etc. on the sugarcane;

[0045] (2) Soaking: at room temperature, soak the cleaned sugarcane in clear water for 36 hours;

[0046] (3) Grinding: put the soaked sugarcane into a grinding machine and grind to obtain sugarcane fibers with a length of 8 cm;

[0047] (4) dry; the sugarcane fiber that step (3) obtains is dried 6h with about 50 ℃ in drier;

[0048] (5) Mixing: the dried sugarcane and the biomass adhesive are mixed according to a mass ratio of 3.5:2 to form a compact, and the resulting compact is a biomass composite material;

[0049] (6) Then cold-press forming the assembly blank at room temperature under a pressure of 5.0MP, and the cold-press forming time is 2 days, and then carry out multiple repairs, polishing and surface waterproofing treatment to obtain a biomass container.

[0050]In this embodiment, the biomass adhesiv...

Embodiment 3

[0052] A method for preparing a biomass plate, comprising the steps of:

[0053] (1) Cleaning; use clear water to wash away the mud on the loofah;

[0054] (2) Soaking: Soak the cleaned loofah in clear water for 24 hours at room temperature;

[0055] (3) Weaving and reorganization: the loofah is cut open and combined, and flattened;

[0056] (4) drying; drying the loofah in step (3) at 50° C. for 5 hours or placing it under natural ventilation for 2 days;

[0057] (5) Mixing: the dried loofah and the biomass adhesive are mixed according to a mass ratio of 2.5:1.5 to form a compact, and the resulting compact is a biomass composite material;

[0058] (6) Then cold-press forming the assembly under normal temperature and a pressure of 6.0MP, and the cold-press forming time is 3 days, and then carry out multiple repairs, polishing, and surface waterproofing treatment to obtain biomass panels.

[0059] In this embodiment, the biomass adhesive is prepared by mixing glutinous rice ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com