Wood-plastic coated solid wood composite material and preparation method thereof

A wood-plastic composite material and composite material technology are applied in the field of wood-plastic clad solid wood composite materials and their preparation, which can solve the problems of easy cracking, low toughness, easy moisture absorption and deformation, etc., so as to enhance surface friction, structure and material properties. Stable and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

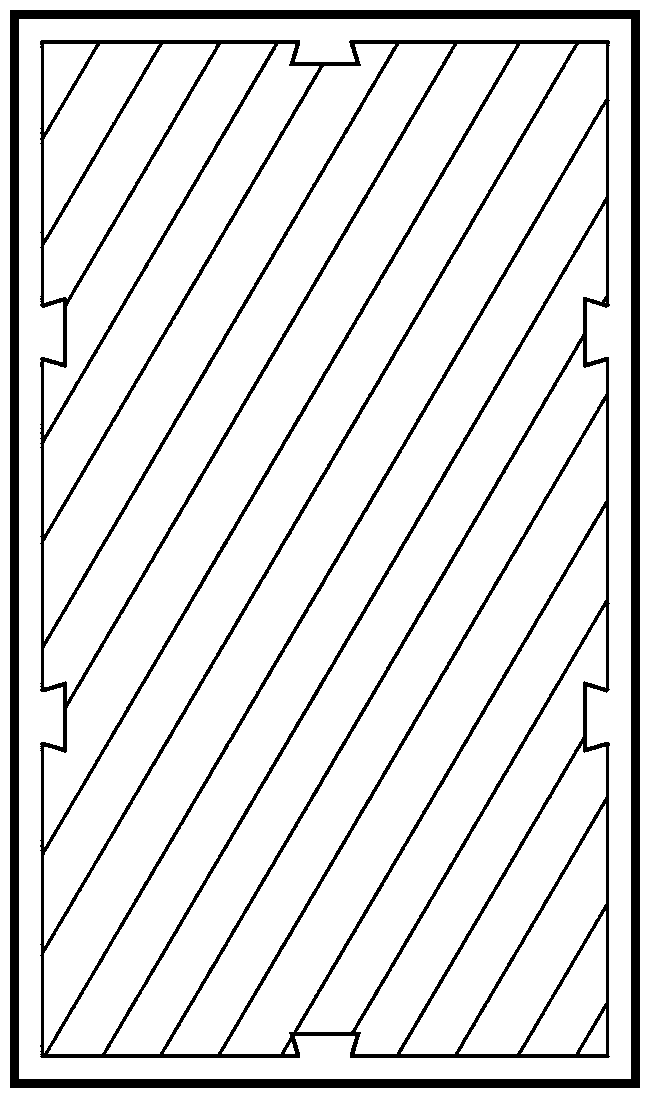

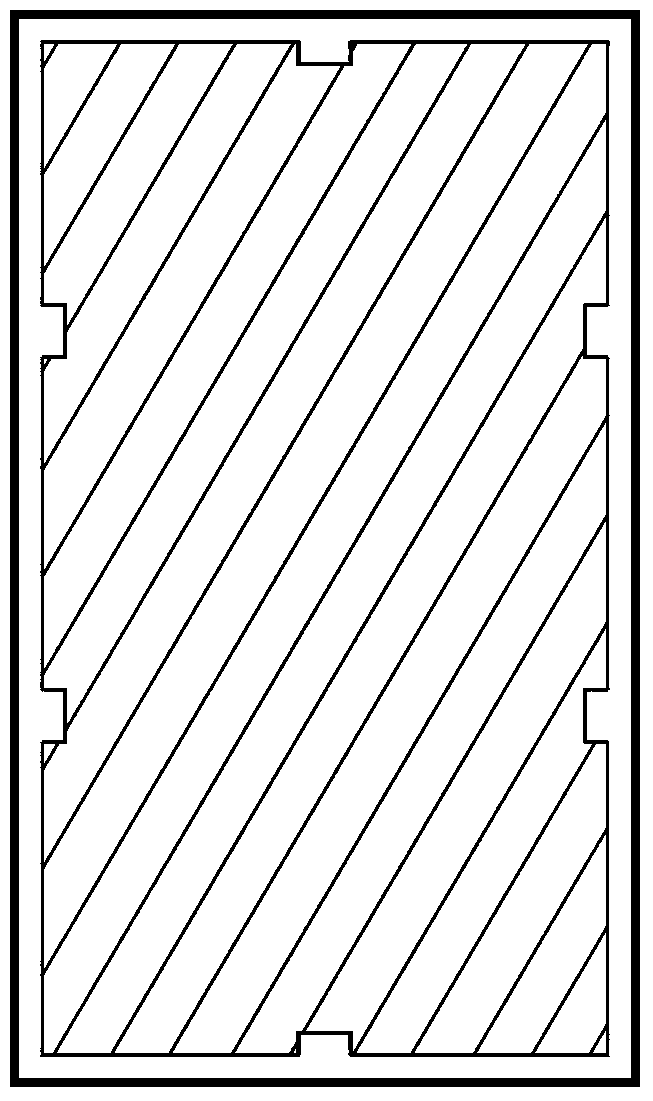

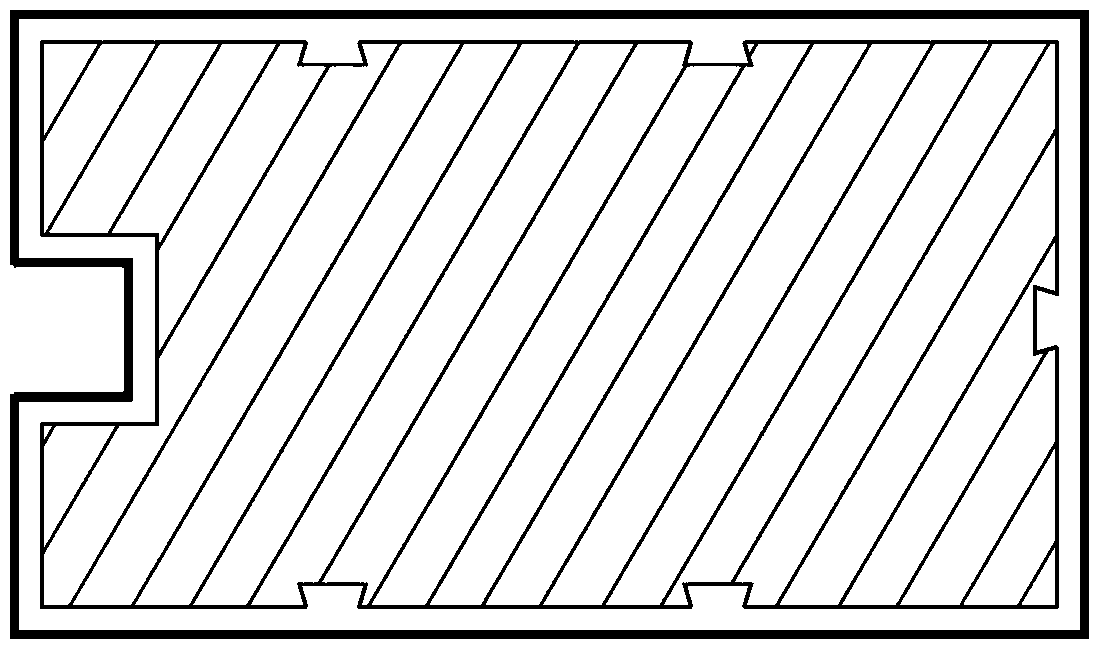

[0014] Embodiment 1: In this embodiment, a wood-plastic-clad solid wood composite material is made by covering a wood-plastic composite material with a solid wood core; the side surface of the solid wood core is provided with grooves.

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solid wood core is obtained by processing grooves on the side surface of solid wood, and the solid wood is sawn solid wood, planed solid wood, finger-jointed wood, and laminated wood. , laminated veneer lumber, reconstituted wood, reconstituted bamboo, modified wood, glue-laminated or compressed wood. Others are the same as the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the groove is a dovetail groove or a square groove. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com