CNC taping machine for winding bar of wind turbine rotor winding bar

A technology for wind turbines and rotor bars, applied in laying solid insulation and other directions, can solve the problems of low degree of automation, low work efficiency, poor wrapping quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

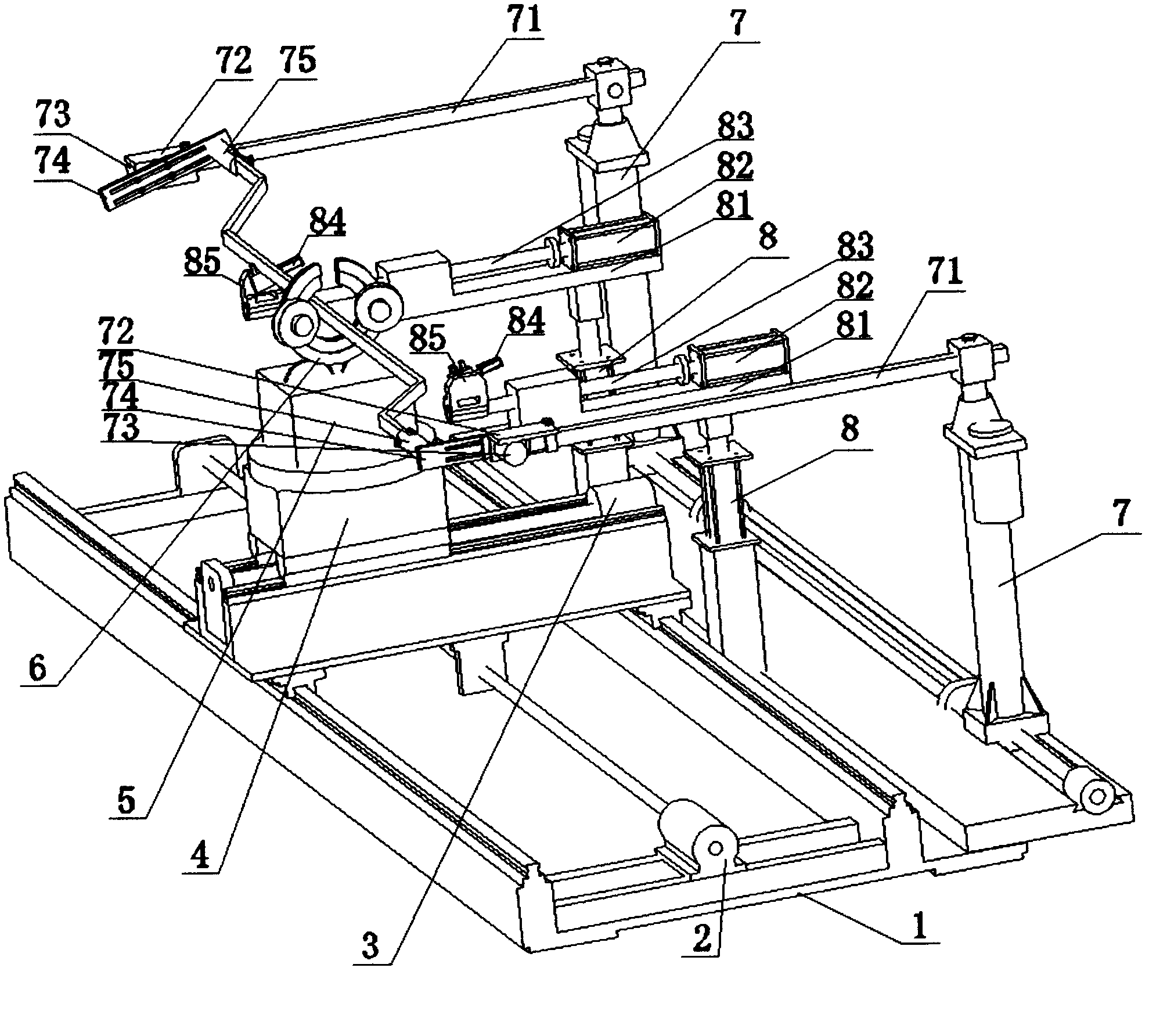

[0010] Such as figure 1 Shown, a kind of wind power generator rotor wire bar numerical control taping machine, a base 1, a tape working mechanism and a wire rod fixing device, the described tape working mechanism is composed of a horizontal servo motor 2 and a wire rod fixing device on the base 1 The platform base 4 driven by the longitudinal servo motor 3 has a rotary working platform 5 driven by a rotary servo motor on the platform base 4, and a taping head 6 is arranged on the rotary working platform 5; the wire rod fixing device includes two The column 7 that can adjust the distance horizontally and adjust the height vertically, the upper end of the column 7 is equipped with a telescopic fixed rod 71 by a fastener, the front end of the fixed rod 71 has a wire rod clamping mechanism, and the wire rod clamping mechanism is driven by a steppin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com