Steering guide wheel set

A technology of guide wheels and guide rods, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, and electrical components. It can solve the problems of low precision, unsatisfactory productivity, and high cost of use, and achieve accurate and reliable angles. Eliminates the effect of uneven force on the belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

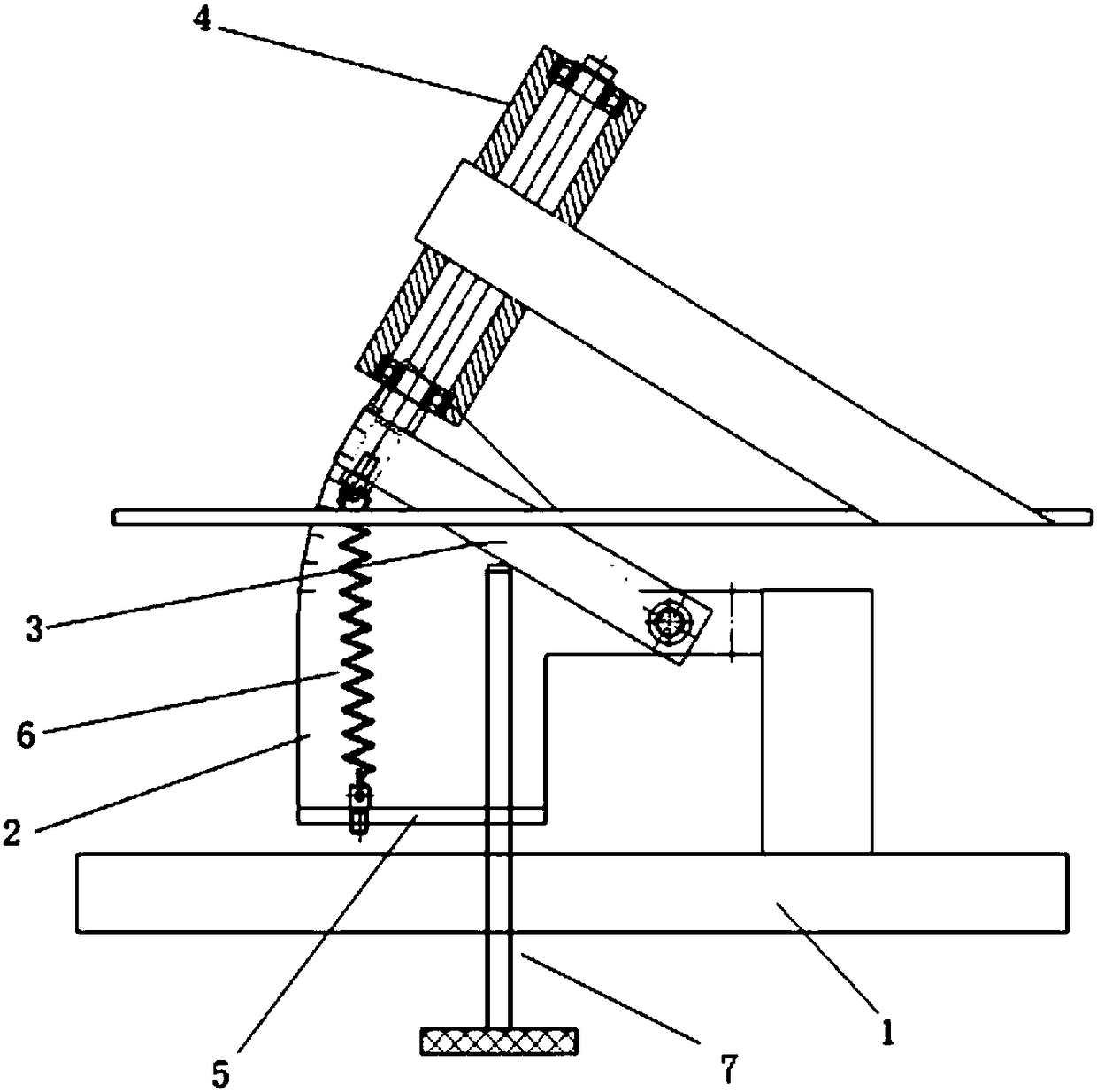

[0016] Such as figure 1 As shown, the tape machine frame 1 is equipped with an active tape unwinding machine, a tension amplifier, and multiple rollers to jointly transmit the tape, and the steering guide wheel group is the final output device for the tape transmission. On the transmission panel of the machine frame 1, the transmission panel is perpendicular to the ground, and a kind of turning guide wheel group of the present invention specifically includes an adjustment platform 2 installed on the tape machine frame 1, and the adjustment platform 2 is parallel to the ground, The adjustment platform 2 is provided with an angle adjustment arm 3 parallel to the adjustment platform 2, one end of the angle adjustment arm 3 is movably connected to the adjustment platform 2, and the other end is provided with a guide rod 4.

[0017] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com