Cloth rewinder tension force adjusting framework

A tension adjustment, cloth rolling machine technology, applied in the direction of winding strips, textiles and papermaking, knitting, etc., can solve the problems of shifting to one side of the cloth winding shaft, belt wear, insufficient friction between the belt and the pulley, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

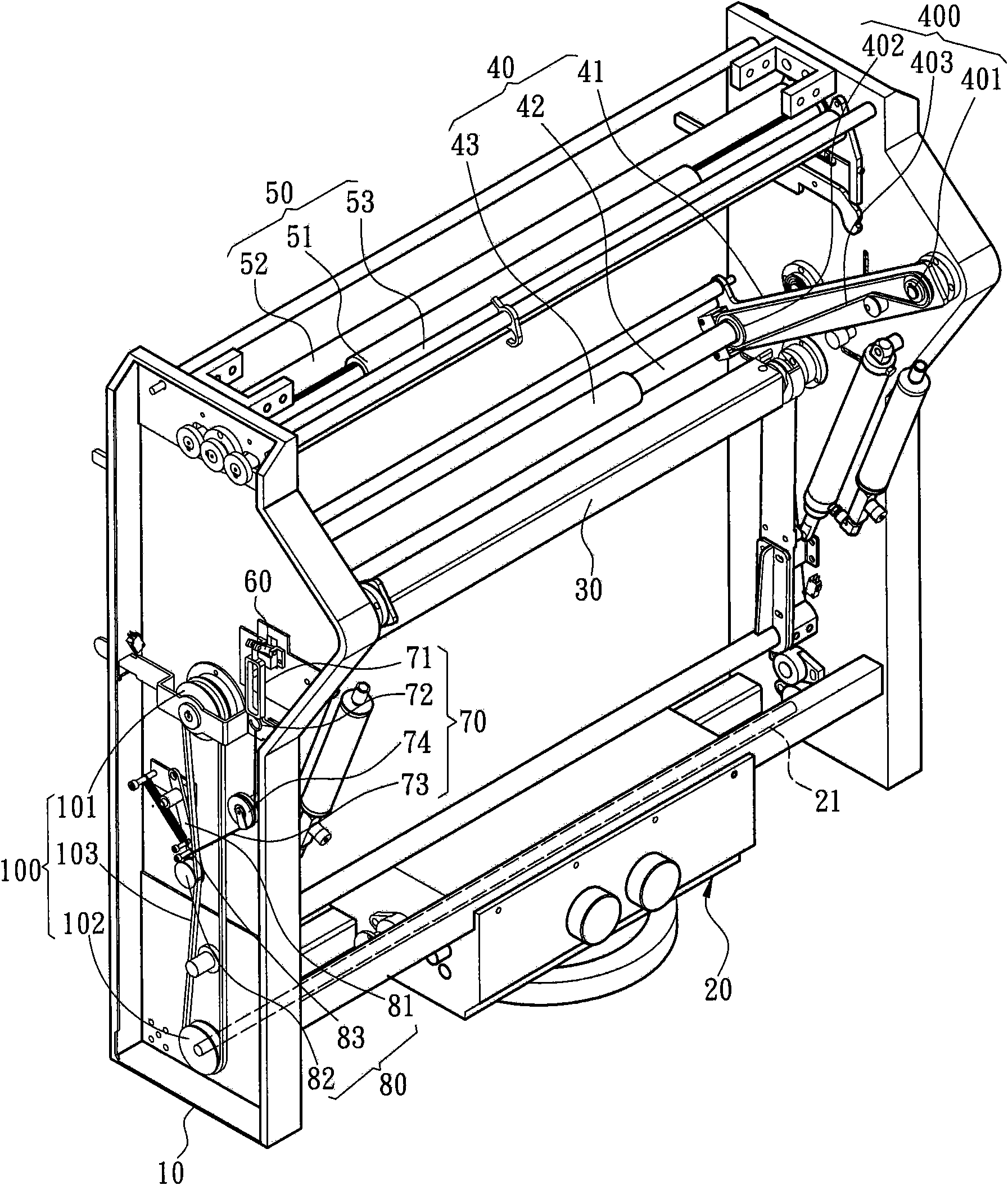

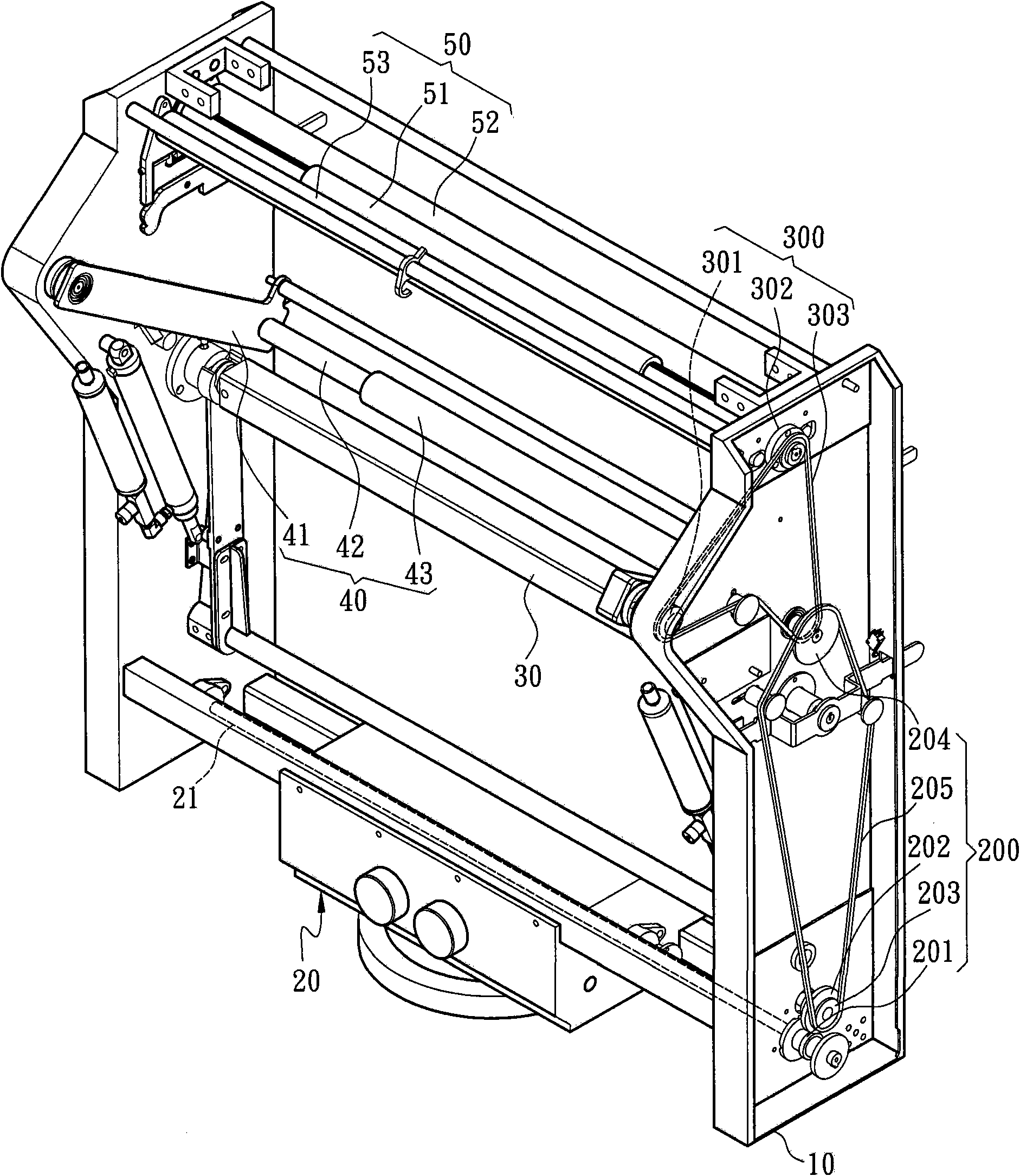

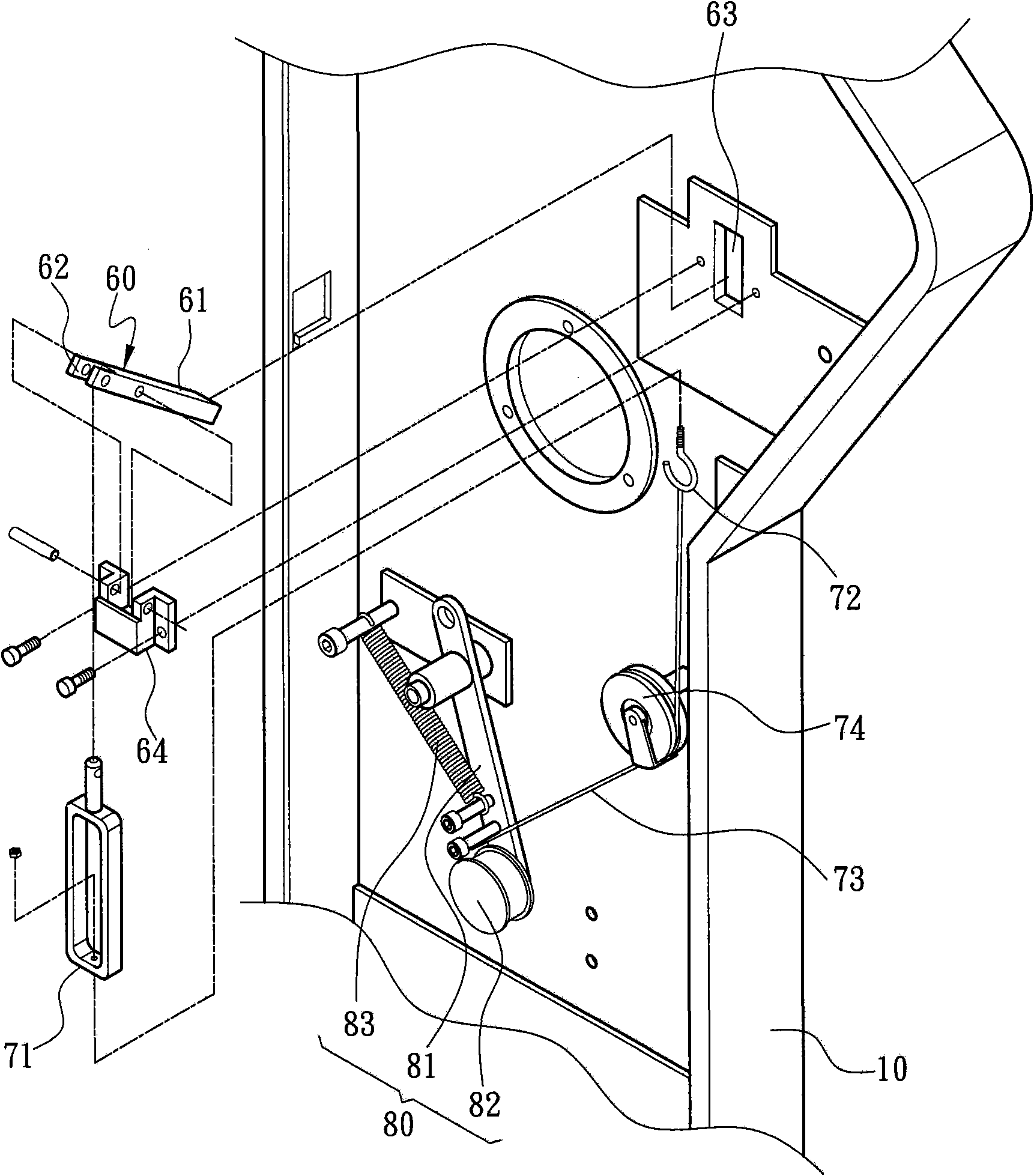

[0018] Relevant detailed description and technical contents of the present invention are as follows now in conjunction with the accompanying drawings:

[0019] refer to figure 1 and figure 2 As shown, the present invention is a tension adjustment structure of a cloth winding machine, the cloth winding machine includes two side boxes 10, and a driving mechanism 20 and a cloth winding bar 30 are arranged between the two side boxes 10 from bottom to top. , a cloth pressing mechanism 40 and a cloth feeding mechanism 50, and the side box 10 is also provided with an adjustment mechanism between the driving mechanism 20 and the cloth pressing mechanism 40. The action of the mechanism 40 is used to adjust the cloth-rolling tension of the cloth-rolling rod 30; wherein, the driving mechanism 20 is arranged at a position close to the bottom between the two side boxes 10, and a shaft 21 is extended from the inside, and the shaft The two ends of 21 penetrate to the inside of the two sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com