Thin film rolling equipment of food packaging bag

A packaging bag and food technology, applied in the direction of thin material processing, transportation and packaging, winding strips, etc., can solve the problems of packaging bag deformation, packaging bag breaking, packaging bag wrinkling, etc., to achieve uniform force, reduce The effect of small tension and uniform diameter enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

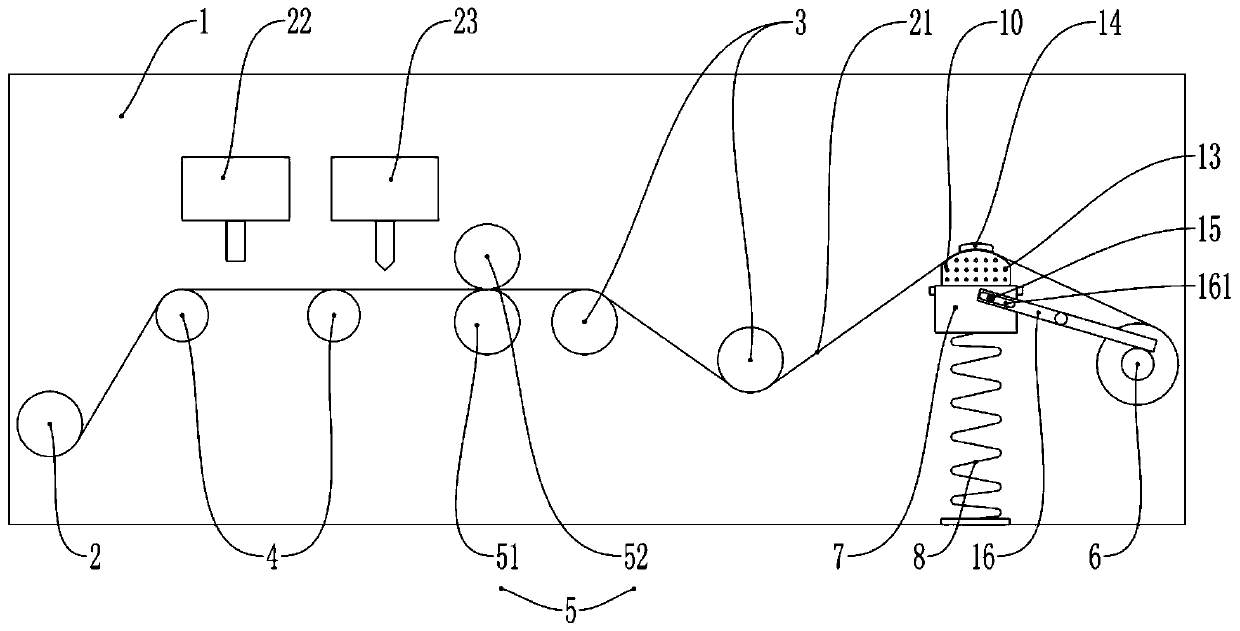

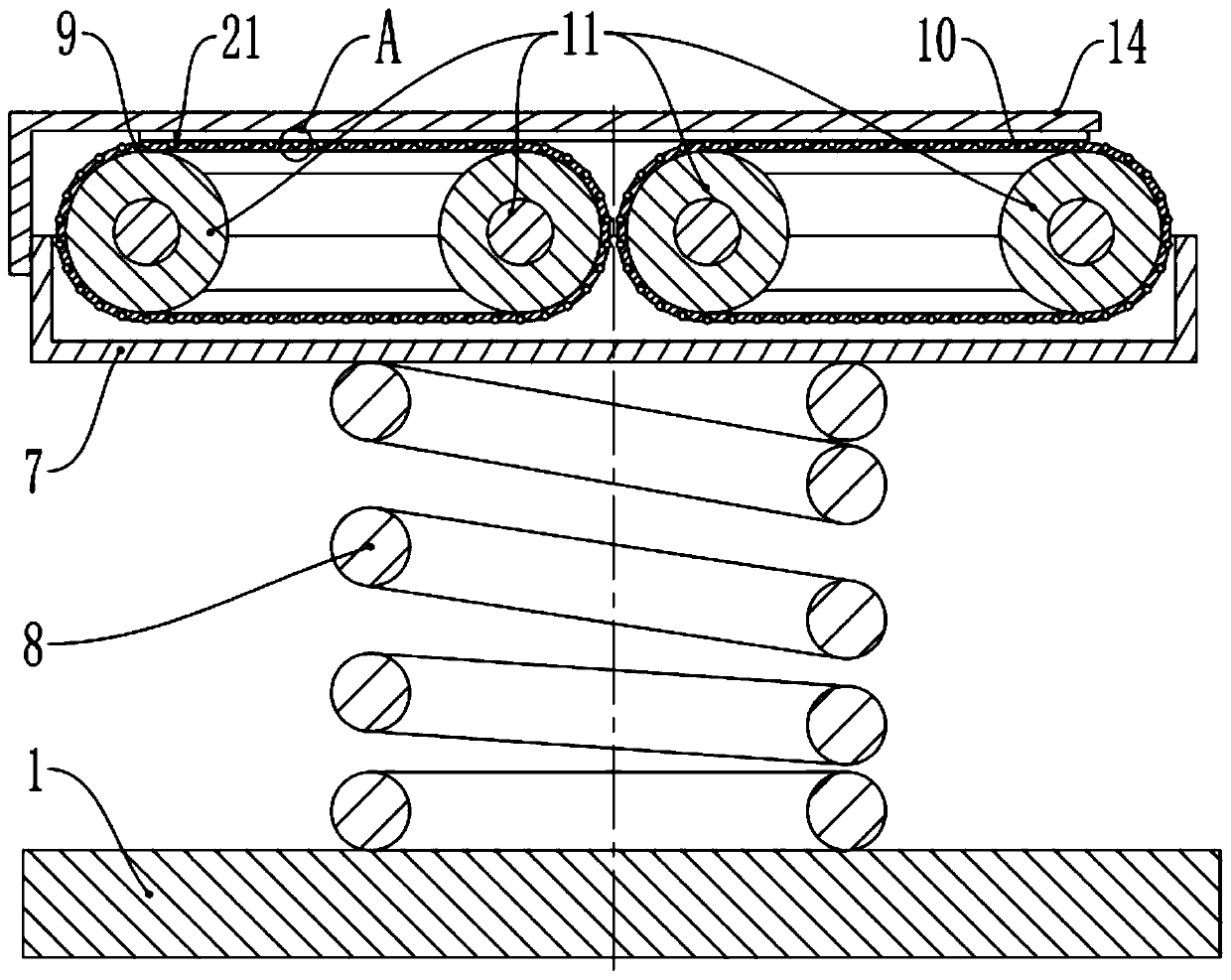

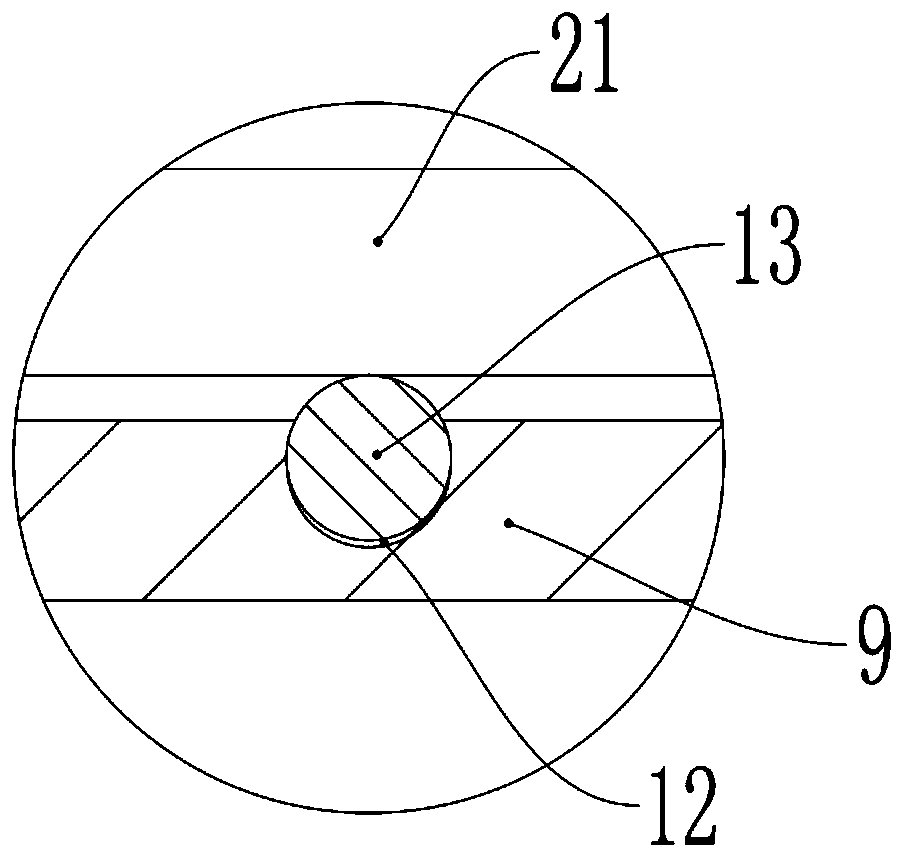

[0029] The reference signs in the drawings of the specification include: frame 1, unwinding roller 2, guide roller 3, driving roller 4, traction roller 5, winding roller 6, adjustment seat 7, first spring 8, first belt line 9 , second belt line 10, pulley 11, groove 12, ball 13, mating plate 14, connecting rod 15, swing rod 16, chute 161, steel roller 51, rubber roller 52, motor 53, gear 54, first transmission Shaft 17, second transmission shaft 18, first bevel gear 19, second bevel gear 20, packaging bag 21, sealing unit 22, dotted line processing unit 23.

[0030] The embodiment is basically as Figure 1 to Figure 4 Shown:

[0031] Film roll material equipment for food packaging bags, including frame 1, on which frame 1 is equipped with unwinding roller 2, driving roller 4, sealing unit 22, point-breaking line processing unit 23, guide roller 3, traction roller 5, and adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com