Binding machine for cigarette case paperboard stacks and binding system

A strapping machine and cardboard technology, applied in the field of strapping machines and strapping systems, can solve the problems of unsatisfactory automation, high-efficiency production, different paper film belts, and low bundling efficiency, so as to achieve strong film feeding stability and save utilization Good effect of space and bundling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

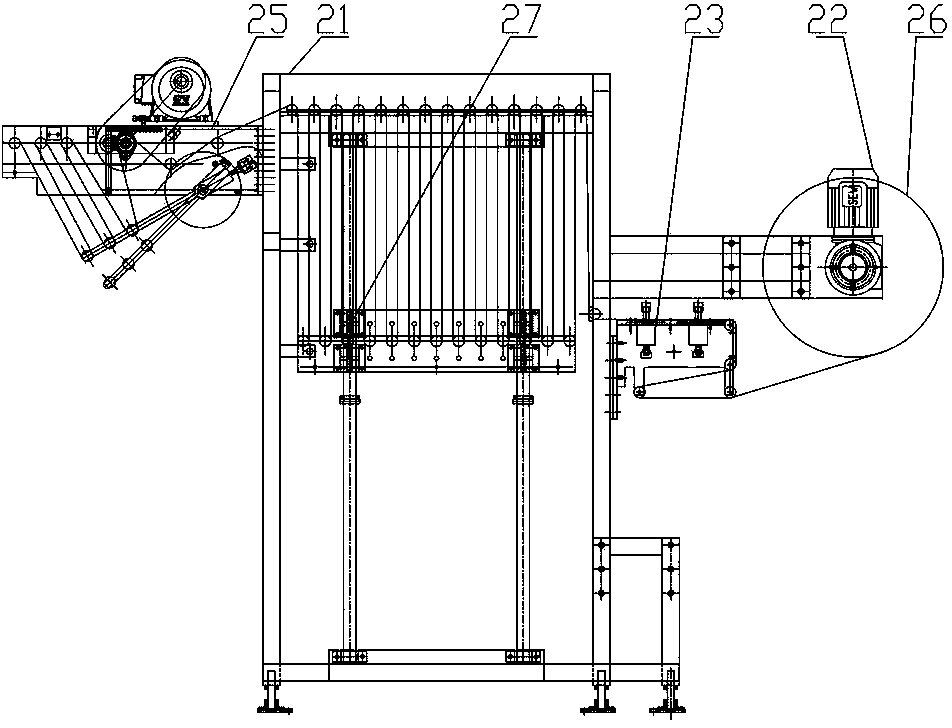

[0056] Such as Figure 11 with Figure 12 As shown, in the binding machine of the present embodiment, the two sides of the horizontal direction of the working platform 8 are provided with the clamping mechanism 4 for clamping the cigarette case cardboard stack 11, and the vertical direction of the working platform 8 is also provided with the clamping mechanism 4 for compressing the cigarettes. The pressing mechanism 7 of the box cardboard pile 11, the clamping mechanism 4 and the pressing mechanism 7 perform the clamping action and the pressing action after the cigarette box cardboard stack 11 is pushed to the working platform 8 and before the film belt 27 is pressed. Such as Figure 14 As shown, the pressing mechanism 7 in this embodiment is located directly above the working platform 8, and the pressing mechanism 7 includes a pressing cylinder 71 and a pressing block 72. For the pressing action of the carton board stack 11, the pressing mechanism 7 is also provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com