Piano automatic chord wrapping machine

An automatic, winding technology, applied in stringed instruments, instruments, etc., can solve the problems of low processing efficiency, low work efficiency, inconsistent tightness, etc., and achieve the effect of improving processing efficiency, high work efficiency, and consistent tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

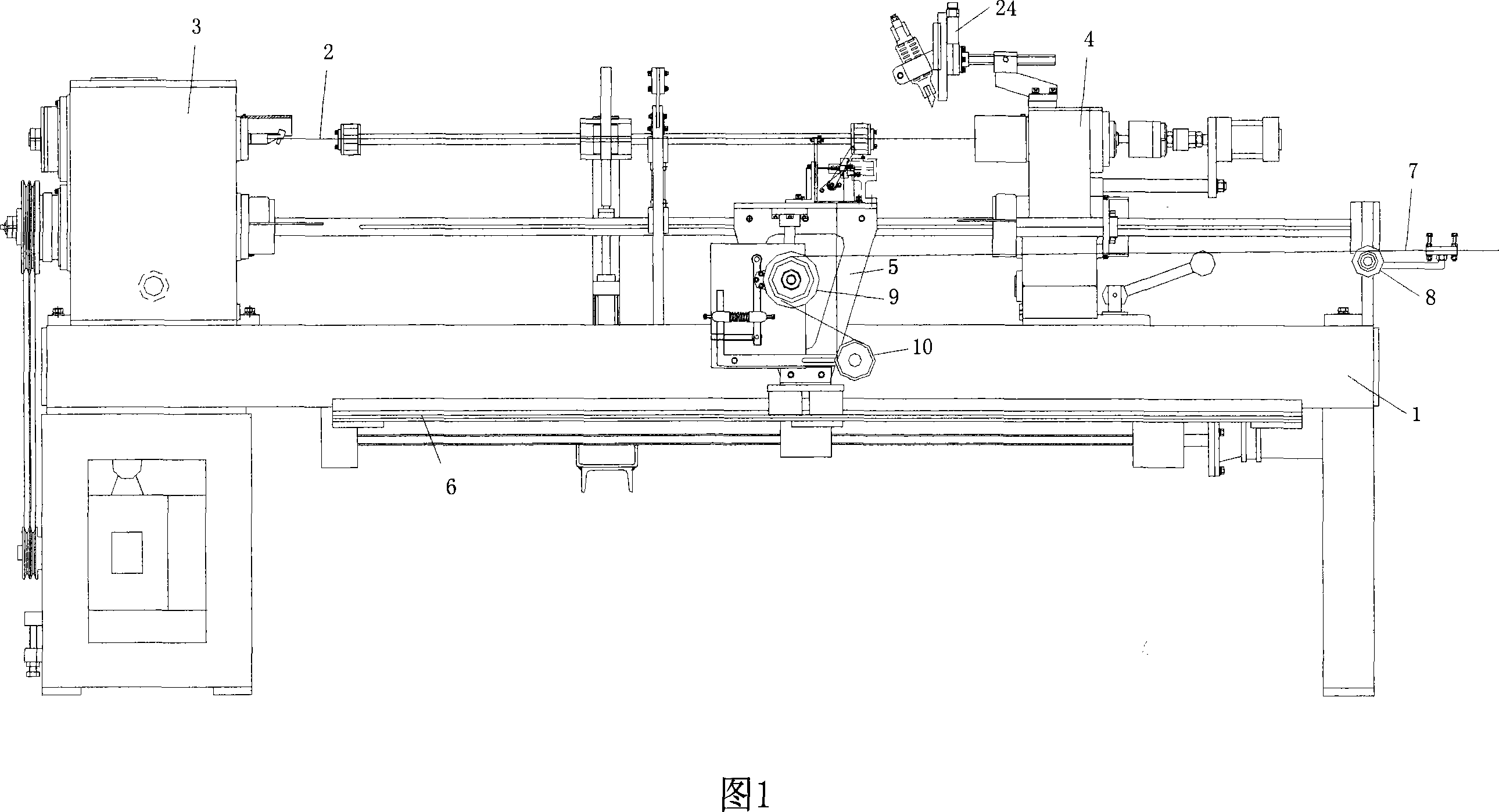

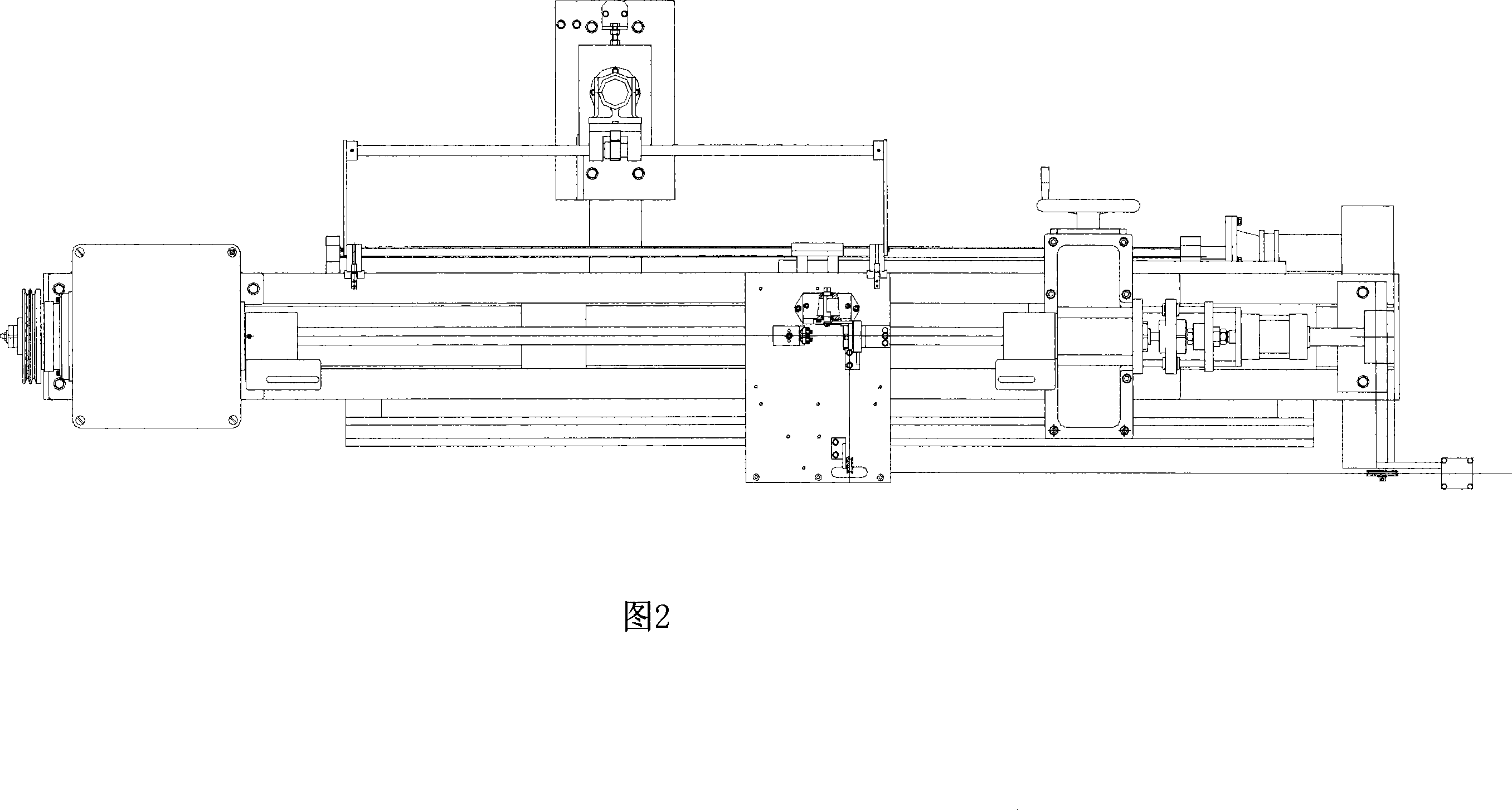

[0031] The automatic piano winding machine shown in Figures 1 to 8 includes a bed frame 1, a headboard box 3 at one end of the fixed steel string 2, and a bedside box 4 at the other end of the fixed steel string 2, and the bedside box 3 and the bedside box 4 Respectively located at the two ends of the bed frame 1, the bed frame 1 is provided with a mobile worktable 5, the mobile workbench 5 forms a movable connection with the bed frame 1 through a screw guide rail mechanism 6, and the mobile workbench 5 can be placed between the bedside box 3 and Move back and forth between the bed end box 4, and the bed frame 1 and the mobile workbench 5 are provided with the wire tightener mechanism of the guide copper wire 7.

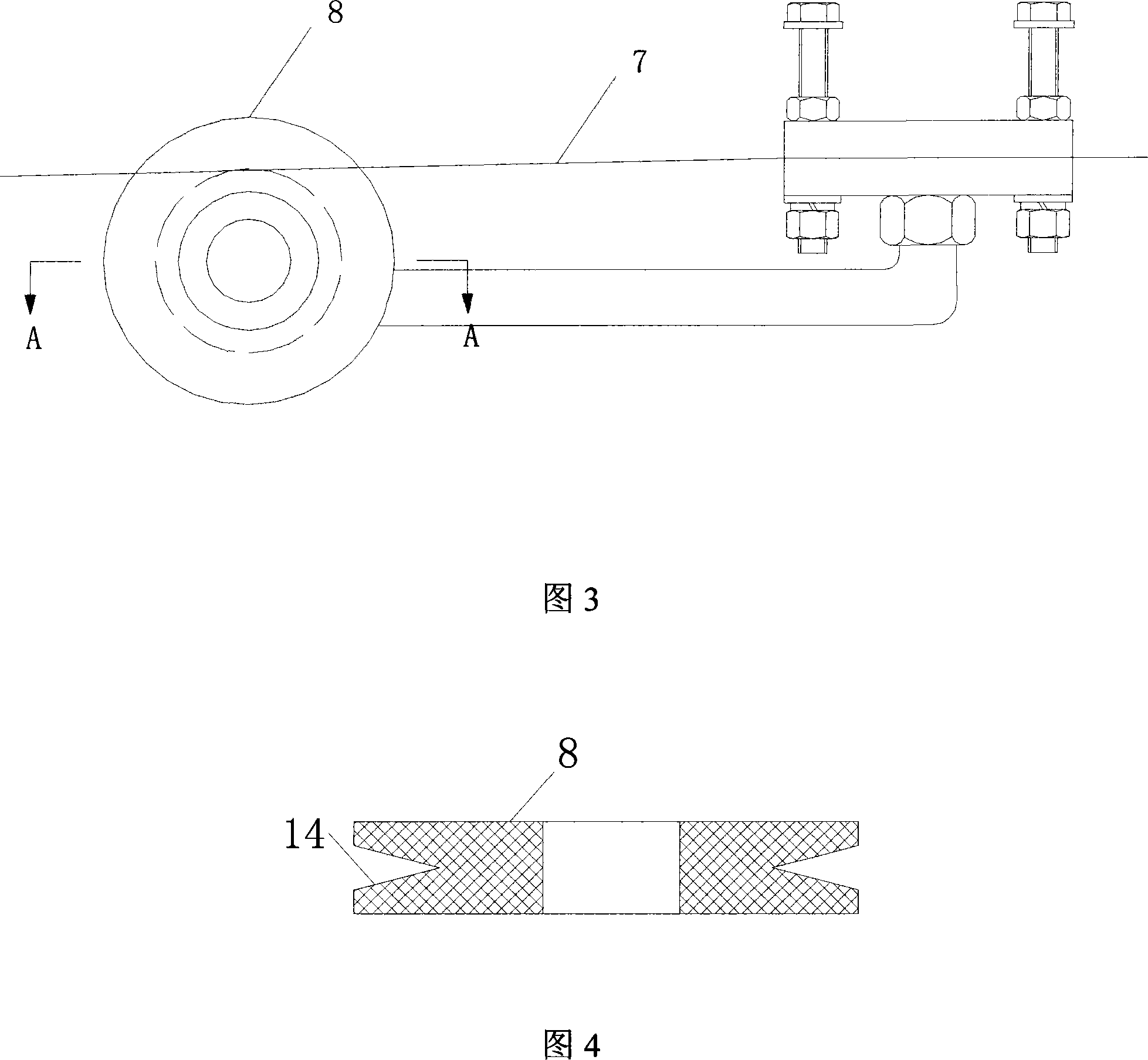

[0032] As shown in Figures 3 to 6, the thread tensioner mechanism includes five guide wheels 8, 9, 10, 11, 12 and a clamping block 13, and the five guide whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com