Tunnel supporting lagging jack and using method

A technology for arch frames and tunnels, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems that affect the quality and safety of engineering construction, the difficulty of controlling the tightness of prefabricated wedges, and the local concentration of loads, etc., so as to improve construction efficiency. The effect of low production cost and roughly consistent degree of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

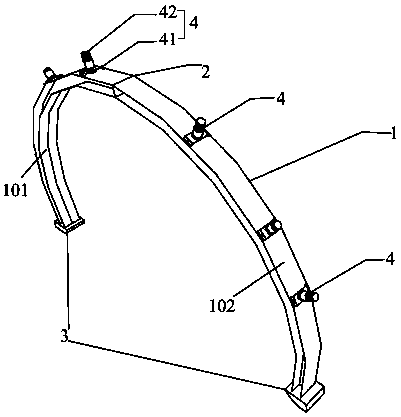

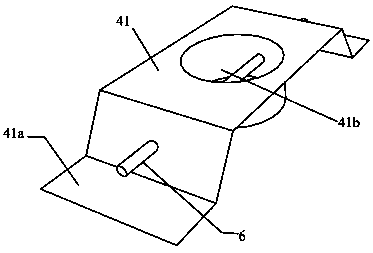

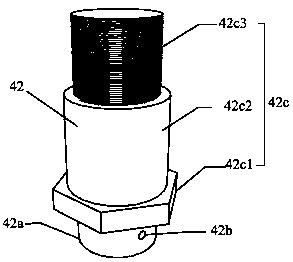

[0055] Tunnel support arches such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes an annular arch main structure 1 arranged along the inner wall of the tunnel, and a plurality of support structures 4 connected to the arch main structure 1, and one end of the support structures 4 is connected to the arch main structure 1 , the other end is provided with a telescopic device 42 that expands and contracts to one side of the surrounding rock 5, so that the support structure 4 can be extended to the surrounding rock 5, and contacts with the surrounding rock 5 to form a support.

[0056] The arch main structure 1 is arranged on the inner wall of the tunnel and arranged circularly along the inner wall of the tunnel, so that after a plurality of support structures 4 are connected to the main arch structure 1, the excavation surface is supported from multiple positions, so that the tunnel support arch has multiple To avoid local excessive concentration of load ...

Embodiment 2

[0072] The use of tunnel support arches, such as Figure 1~4 As shown, when using the tunnel supporting arch as in Embodiment 1, follow the steps below:

[0073] a. Prefabricated and spliced arch main structure 1;

[0074] b. Determine the support point;

[0075] c. Install the support structure 4;

[0076] d. Operate the telescopic device 42 so that the telescopic device 42 is against the excavation surface of the surrounding rock 5;

[0077] e. Step c and step d are repeated until all supporting structures 4 are installed.

[0078] During operation, the extension length of the telescopic device 42 is adjusted according to the distance between the arch main structure 1 and the surrounding rock 5, so that the support structure 4 presses the surrounding rock 5 tightly to ensure that each position of the arch main structure 1 The degree of tightness is roughly the same, so that the tunnel supporting arch is evenly stressed, ensuring the safe and reliable operation of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com