Efficient heat-setting spinning thread processing machine with uniform oil

A treatment device and heat setting technology, applied in textiles and papermaking, etc., can solve problems such as the difference in tightness between the inner and outer rings, affect the winding effect, and high labor intensity, and achieve simple structure and improved oiling. Uniformity, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

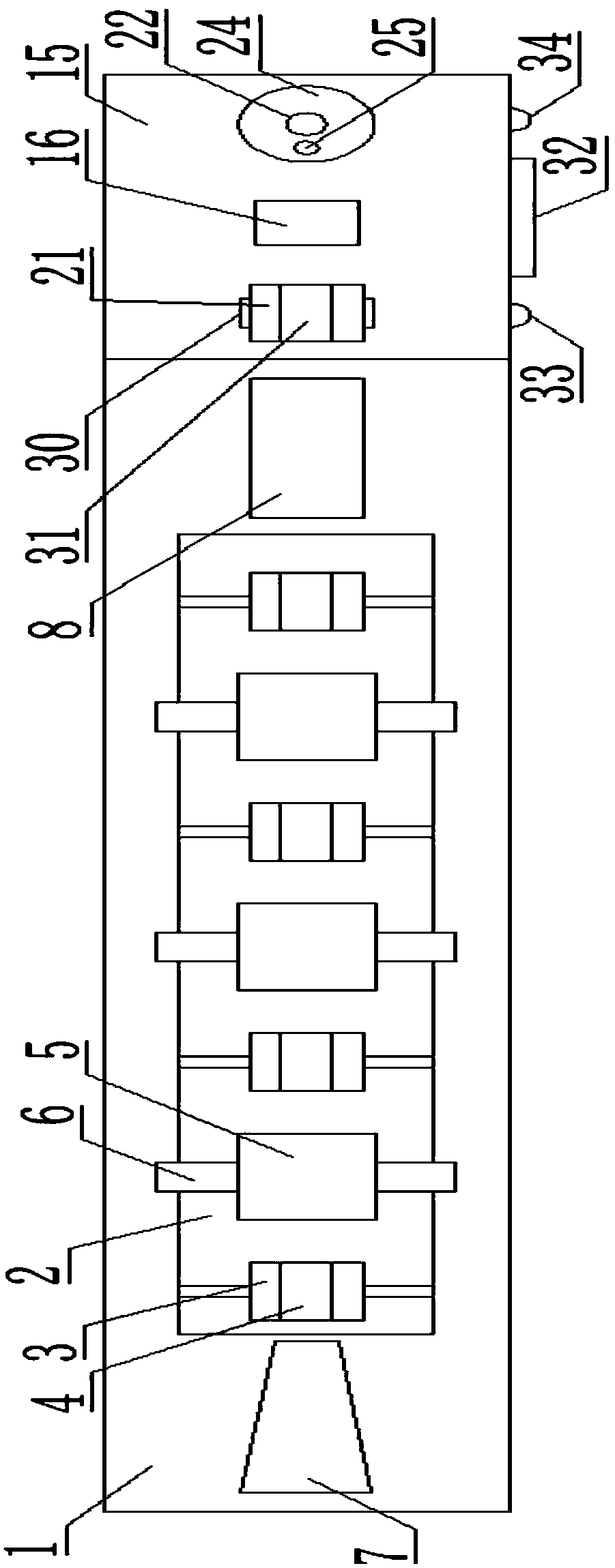

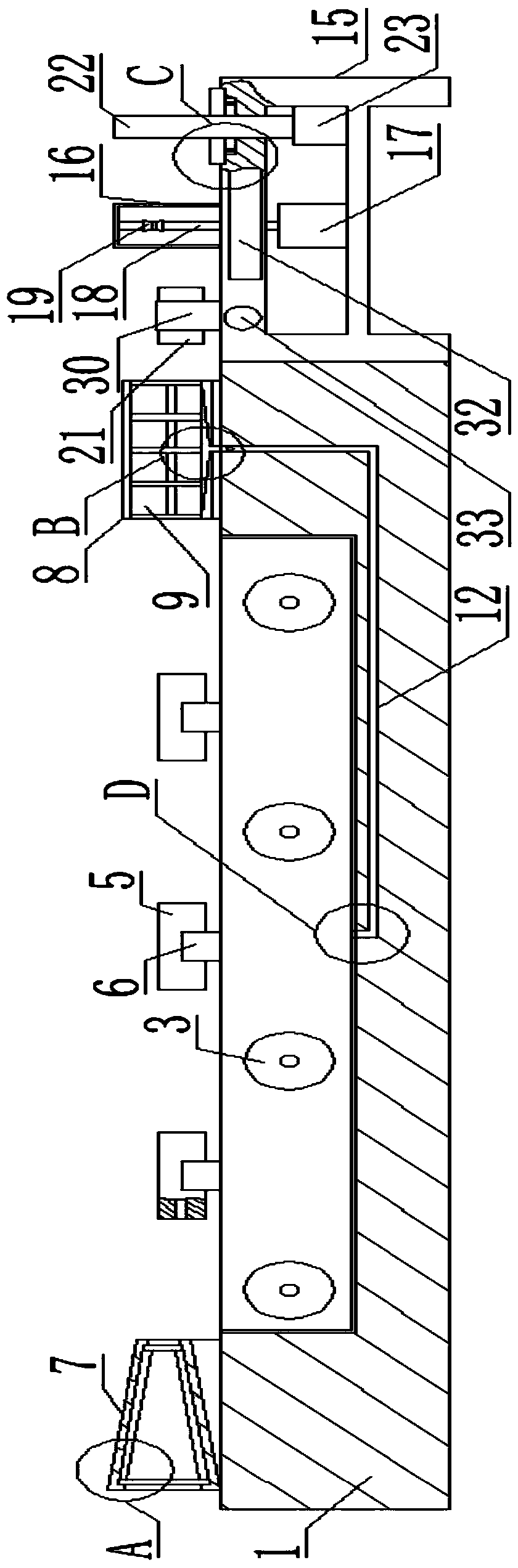

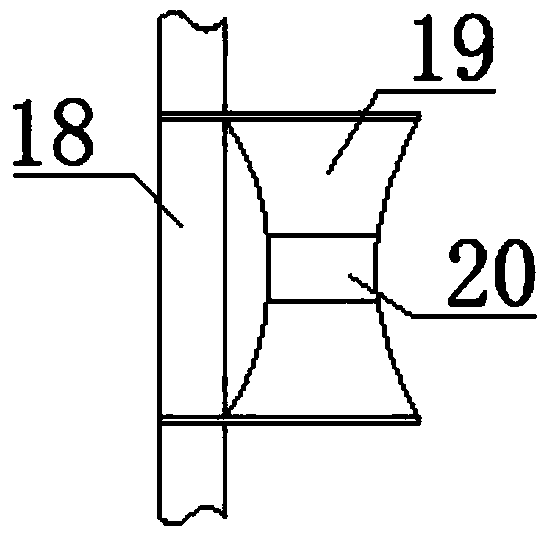

[0022] Example. High-efficiency heat-setting spinning processing device with uniform oiling, consisting of Figures 1 to 8 As shown, it includes a housing 1, and the housing 1 is provided with a first groove 2; a plurality of evenly distributed oiling rollers 3 are arranged in the first groove 2, and each oiling roller 3 is provided with an oiling groove 4; a heating plate 5 is arranged between every two adjacent oiling rollers 3, and each heating plate 5 is equipped with two inclined supporting rods 6; one side of the first groove 2 is provided with The dust removal channel 7 is provided with an oil return channel 8 on the other side; a plurality of evenly distributed first sponge rings 9 are installed in the oil return channel 8, and an oil outlet 10 is provided in the middle of the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com