Overturning stacking machine

A stacker and turning mechanism technology, applied in the field of turning stackers, can solve the problems of large turning power consumption, high cost, long turning time, etc., to achieve favorable turning operation, high production efficiency, and high paper delivery efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

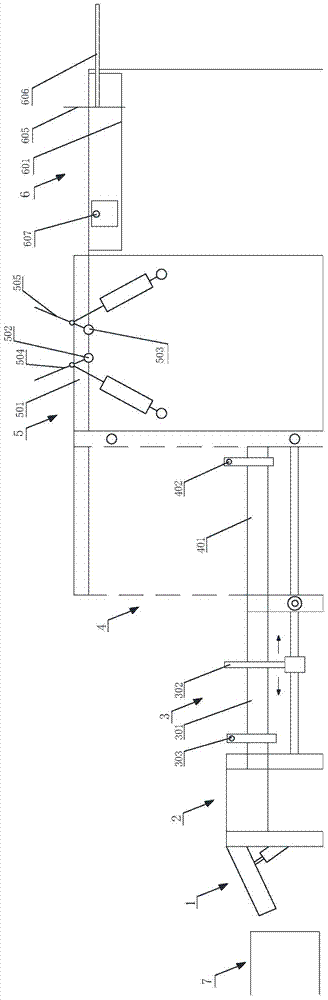

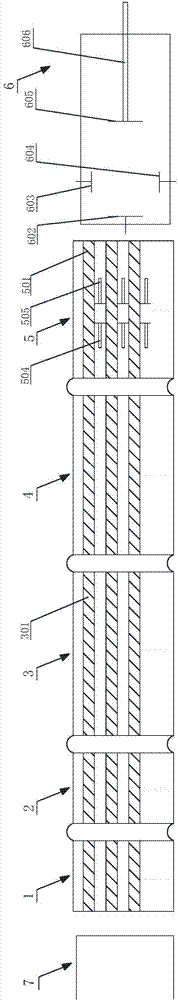

[0024] refer to figure 1 with figure 2 , a reversing stacker, including a buffer paper separation part, a chopping part 3, a reversing part 5 and a stacking part 6 arranged in sequence from front to back, and a lifting conveyor is arranged between the chopping part 3 and the reversing part 5 Section 4; the overturning section 5 includes an overturning mechanism and several overturning section conveyor belts 501 arranged in parallel along the conveying direction of the cardboard, and the overturning mechanism includes two overturning section conveyor belts located below The first rotating shaft 502 and the second rotating shaft 503 arranged radially, the first rotating shaft 502 is located in front of the second rotating shaft 503, the first rotating shaft 502 and the Front fender teeth 504 and rear fender teeth 505 are respectively arranged on the second rotating shaft 503 , and the positions and numbers of the front fender teeth 504 and rear fender teeth 505 correspond to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com